Frame for suctioning filling gases and transferring same into the gas collection chamber of the oven chamber of a stamping battery during the setting of a stamped cake in the oven chamber, with reduction of the filling emissions

A technology for filling gas and collecting chambers, which is applied in the heating of coke ovens, coke ovens, charging devices, etc., which can solve the problem of insufficient sealing between tamping briquettes and irregular surfaces, and the inability to completely prevent filling gas from escaping and tamping Avoid problems such as briquette mechanical contact damage, achieve the effect of preventing filling discharge, simple structure, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

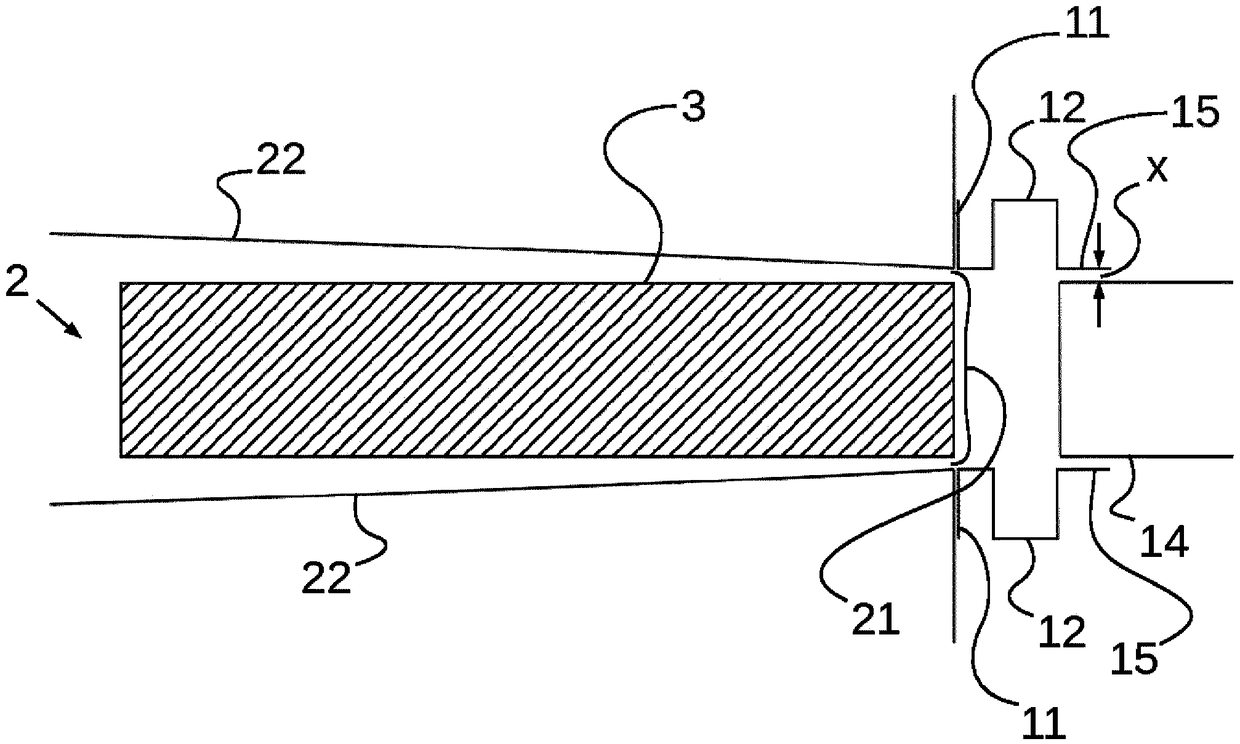

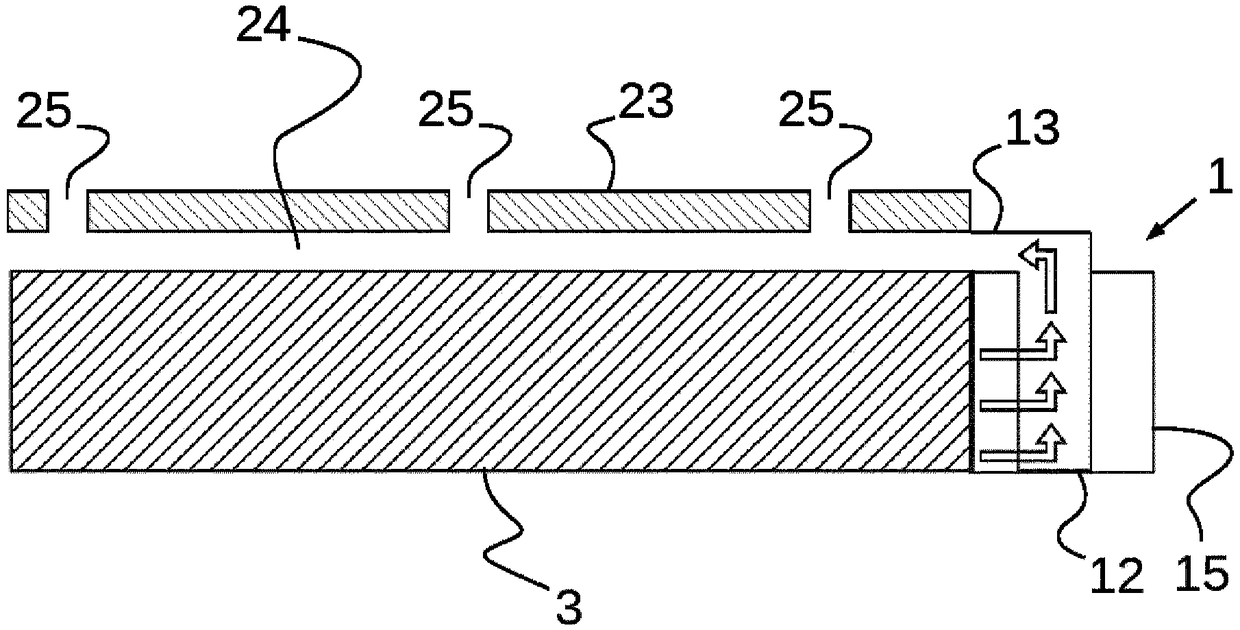

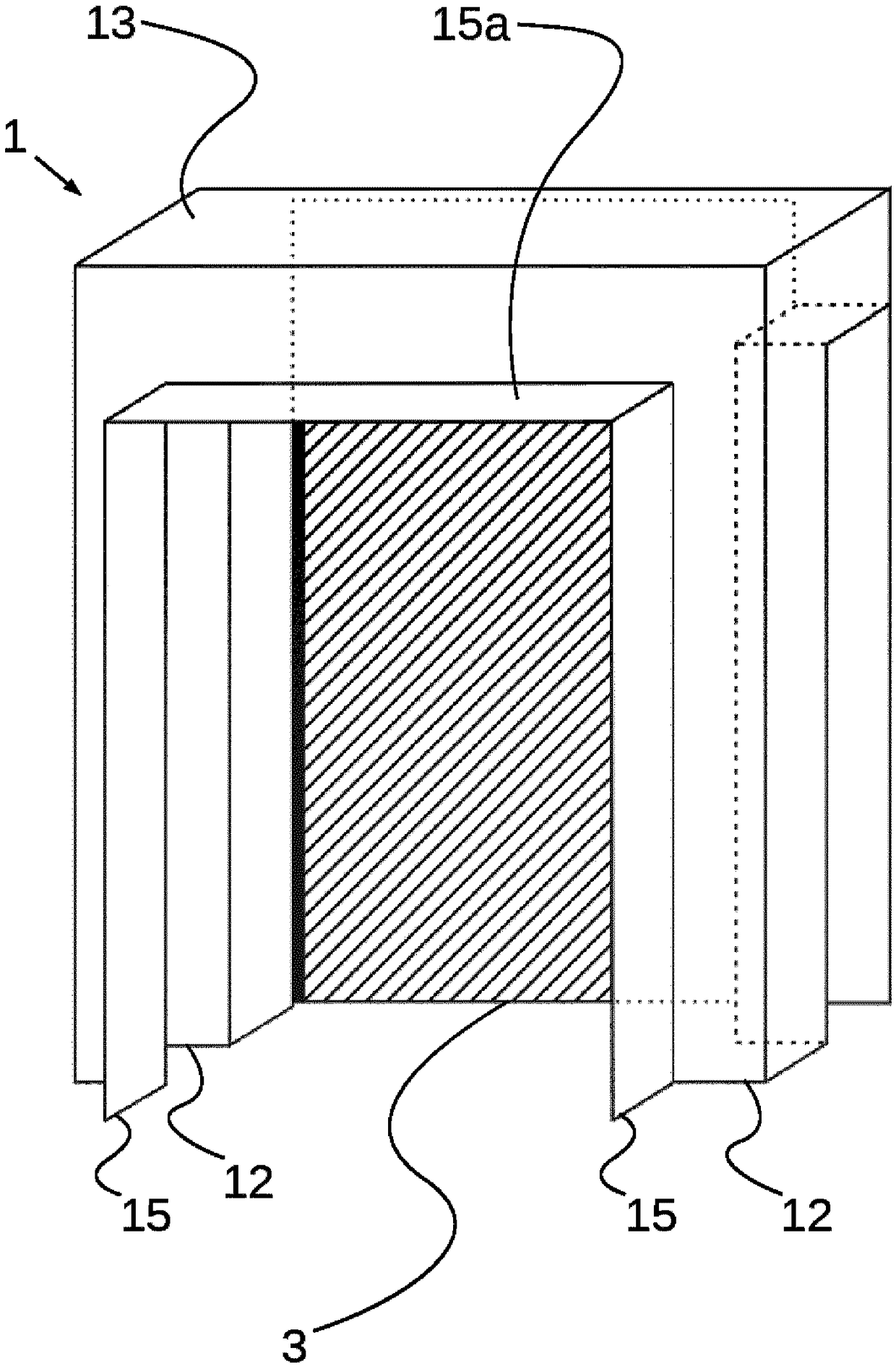

[0032] figure 1 A horizontal section through a coke oven chamber with a device for extracting and diverting filling gas according to an exemplary embodiment of the invention is shown. The coke oven chamber 2 has a typical elongated shape along the charging direction, in figure 1In , the loading direction extends from right to left. The charging opening 21 is arranged at the right-hand end (machine side) of the coke oven chamber 2 . The rammed briquettes 3 have been introduced through the filling opening and are completely accommodated in the coke oven chamber 2 . The coke oven chamber 2 is delimited at its sides by oven walls 22 . The oven wall 22 is tapered in the charging direction, so that the coke oven chamber 2 is wider on the coke side facing away from the charging opening 21 than on the machine side. As a result, the processed coke can be pushed out against the furnace wall 22 with reduced friction.

[0033] The important element of the device according to this emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com