Improved process compatibility through fill factor modulation

一种周期性、目标的技术,应用在计量领域,能够解决降低目标性能及装置-目标相似度、影响工艺兼容性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Before setting forth the detailed description, it may be helpful to clarify the definitions of certain terms that will be used hereinafter.

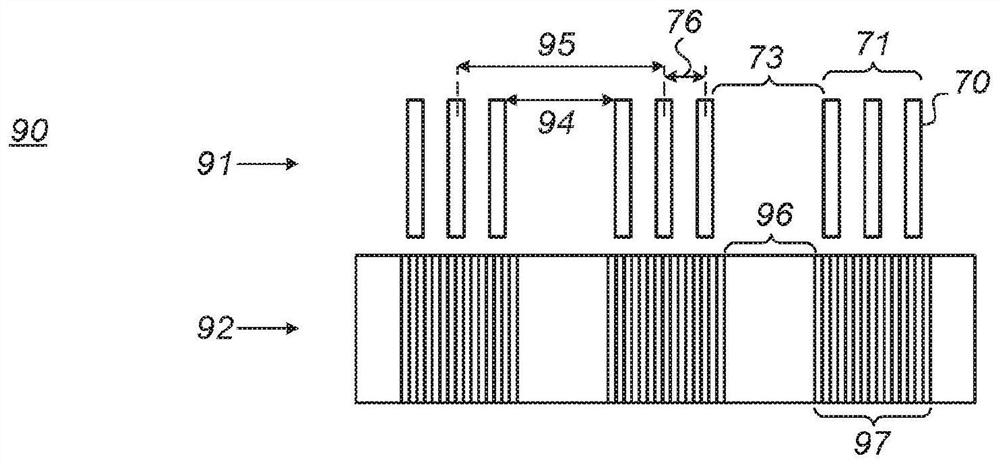

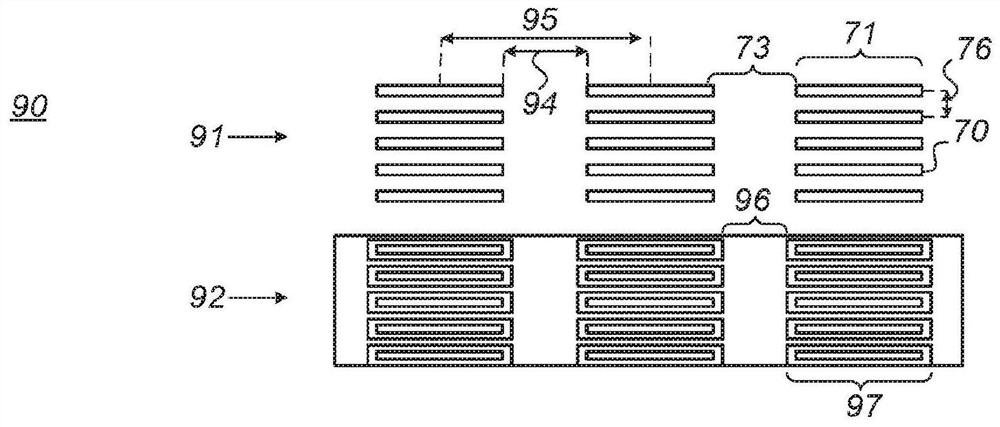

[0024] As used in this application, the terms "element", "target element" and "auxiliary element" refer to the part of a metrology object (especially an imaging object) at any of its stages of manufacture, such as the design stage, optical masks, resists, various fabrication steps and resulting objects. Typically, metrology targets include periodic structures with repeating elements to which the present invention is concerned. For example, the target element may be on a reticle used to transfer the target design to the wafer. It is clearly noted that although the physical properties of the objects differ at various stages of fabrication, the disclosed design principles and resulting structures are not limited to any particular fabrication step, and can be related to the Either applies. It should be emphasized that similar desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com