Hot-rolled strip temperature and strip shape synchronous online detection device

A detection device and hot-rolled plate technology, which is applied in the direction of length measuring device, metal rolling, metal rolling, etc., can solve problems such as not considering the influence of temperature, achieve easy installation and maintenance, good market application prospects, and improve precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further elaborated below in conjunction with accompanying drawing:

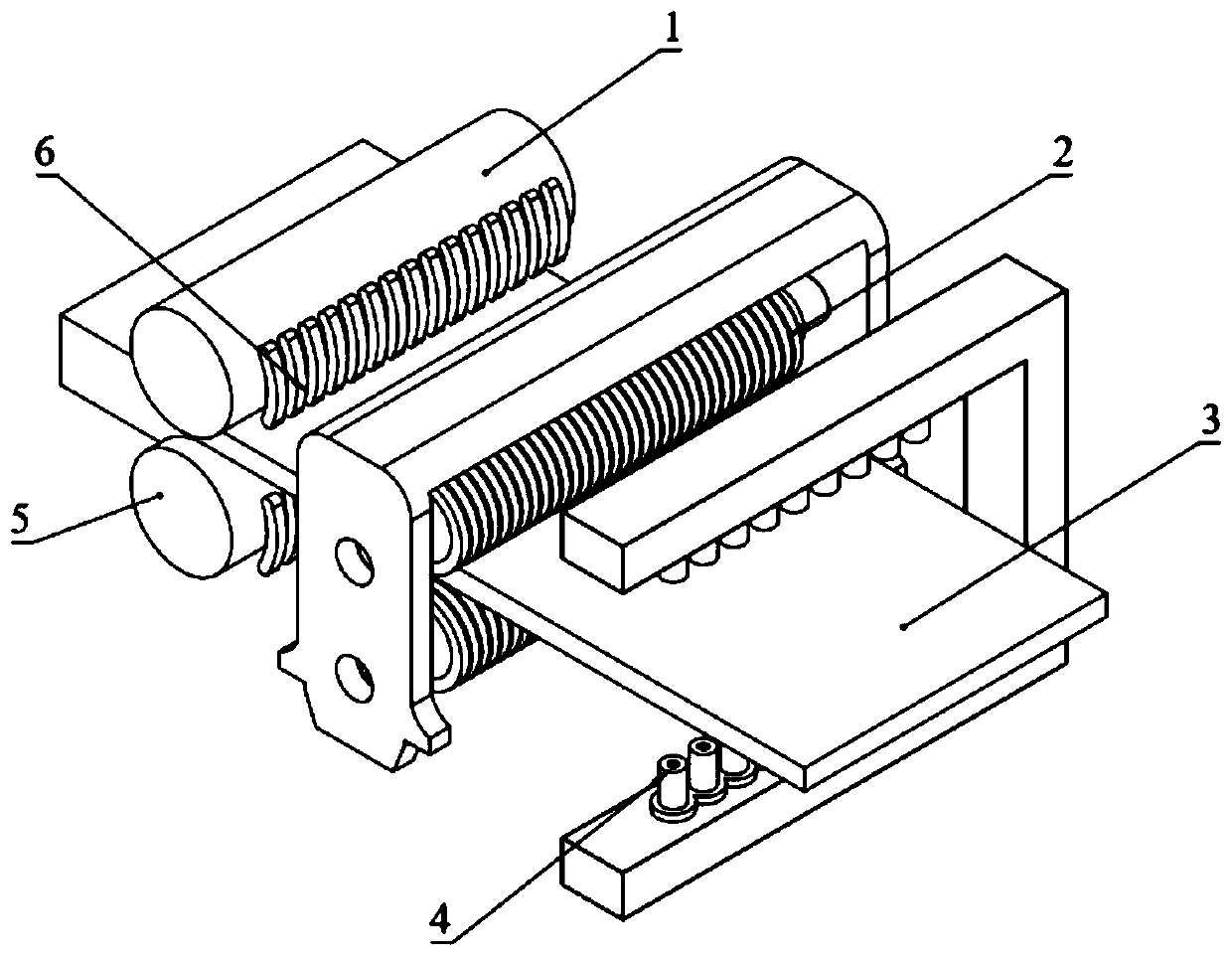

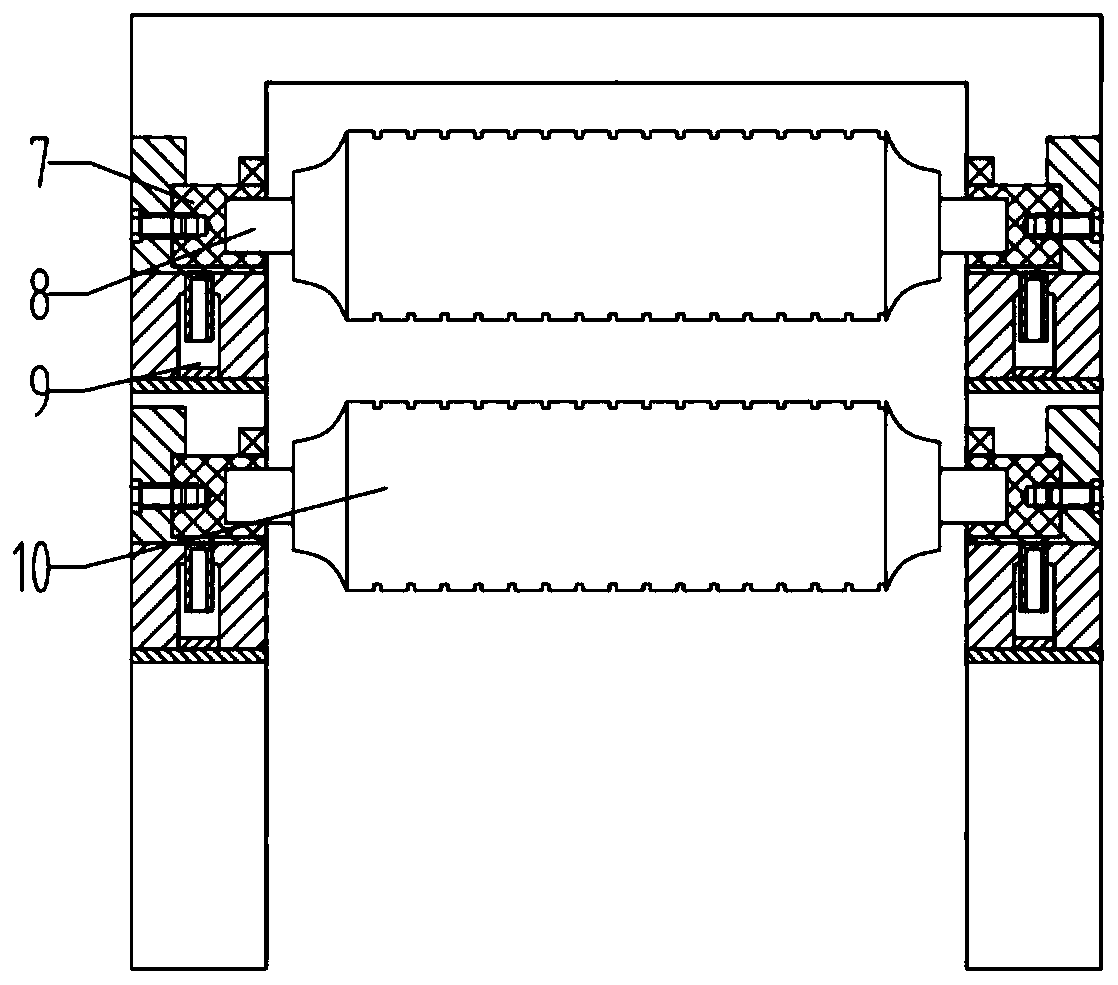

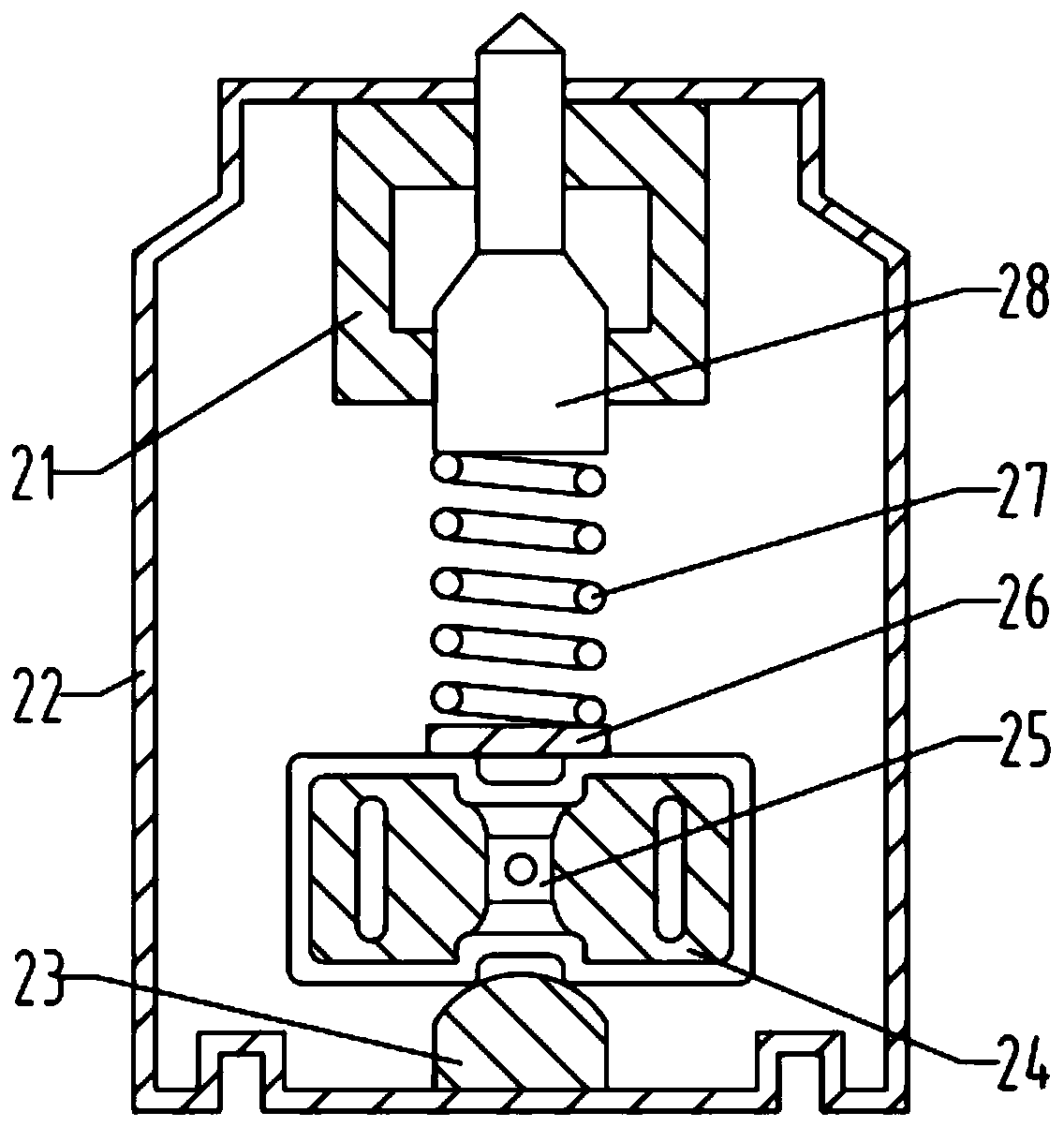

[0037] Such as figure 1 As shown, the hot-rolled strip temperature and flatness synchronous detection device of the present invention mainly includes a flatness detection device 2, a temperature measurement device 4, a cooling device 6 and a signal processing module. The measuring roller 10 of the plate shape detection device is in direct contact with the surface of the plate strip 3 to be tested, and accurate plate shape signals are obtained through the measuring probe 28 and the pressure sensor.

[0038] The temperature measurement device 4 uses an infrared thermal imager 46 to collect the lateral temperature distribution of the online strip, and obtain the temperature field information of the strip. The signal processing module receives the shape signal and temperature information, and realizes the temperature error compensation of the shape through data conversion and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com