Continuous spring connected spring box type oven

A spring box, box-type technology, applied in the field of processing and manufacturing, can solve the problems of uneven heating between the middle and the edge, large smoke and unenvironmental protection, and large oven volume, etc., to achieve enhanced shaping effect, good shaping effect, and good working environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

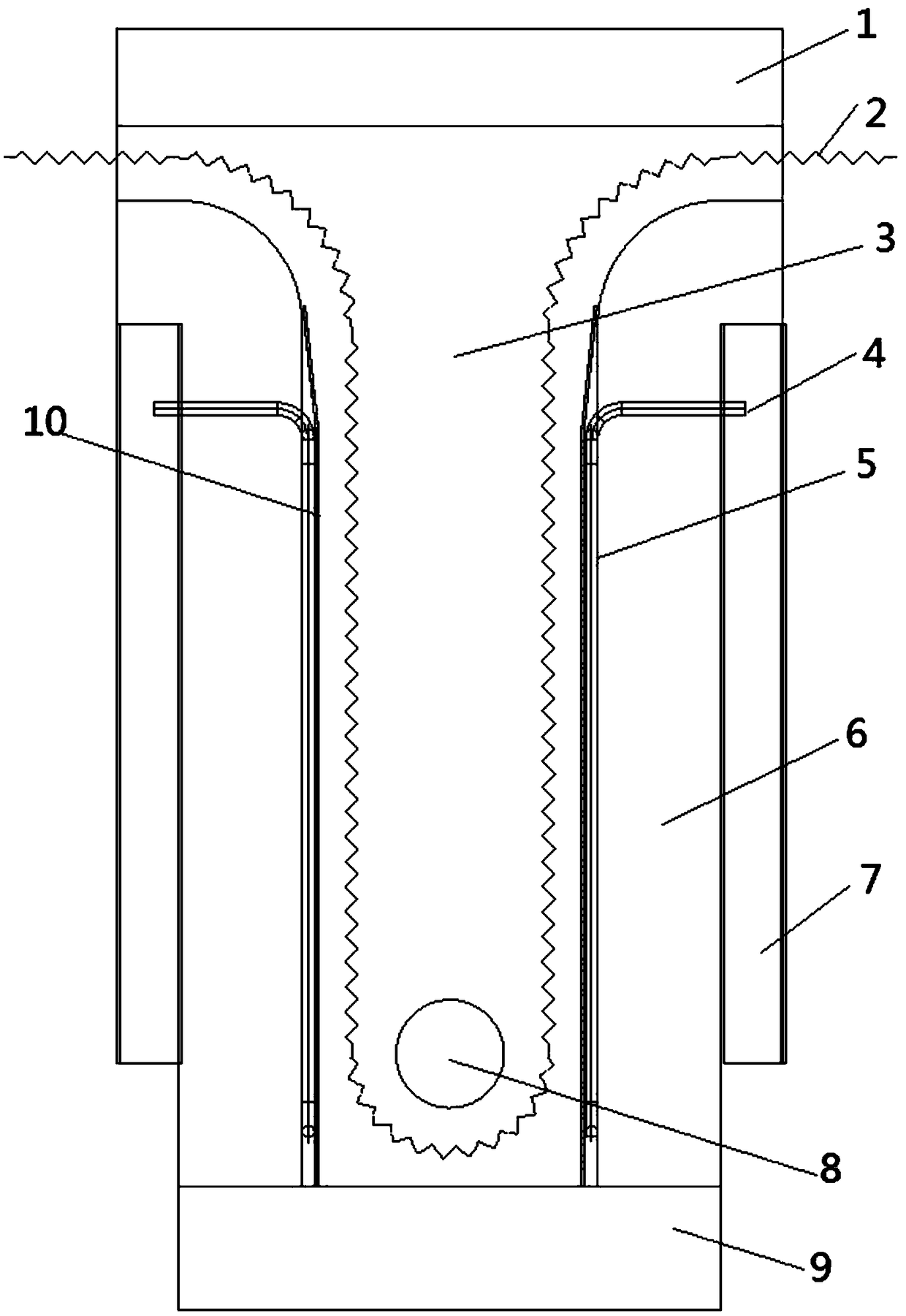

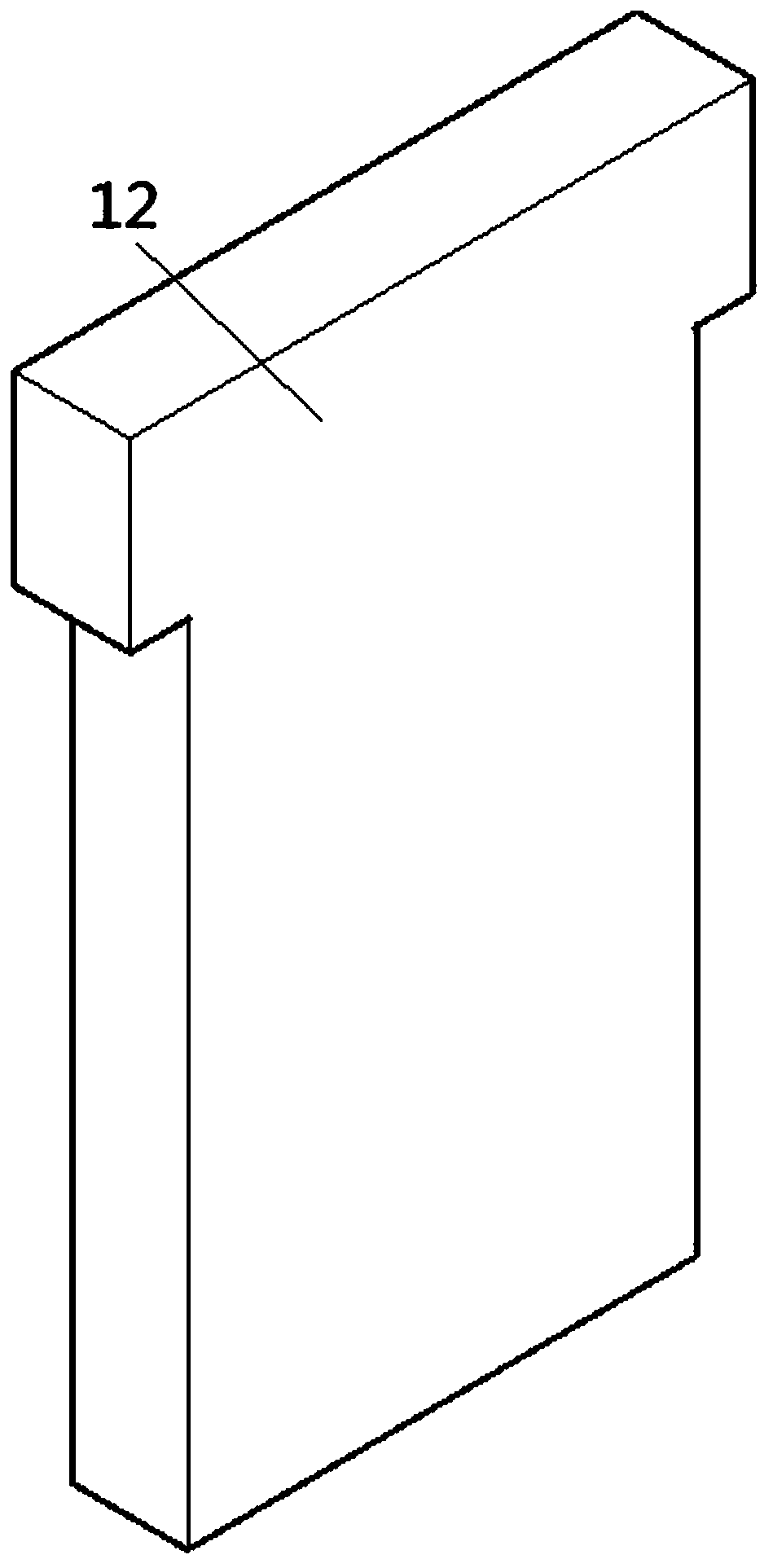

[0019] see figure 1 , figure 2 , Figure 4 , a box-type oven in the embodiment of the present invention, comprising a vertically arranged support installation plate 3, the upper end of the support installation plate 3 protrudes forward horizontally and is provided with an upper end insulation layer 1, and the lower end of the support installation rod faces toward the The front horizontal extension is provided with a lower end insulation layer 9, which is characterized in that the front end of the support installation plate 3 is vertically arranged with an installation insulation layer 6 symmetrically, and the opposite end faces of the installation insulation layer 6 on the left and right sides are all vertically arranged. There is a protective plate 10, and a spring 2 is provided in conjunction with the rotating drum 8, and the upper end of the installation insulation layer 6 is provided with a spring inlet and outlet in conjunction with the upper insulation layer 1, and the...

Embodiment 2

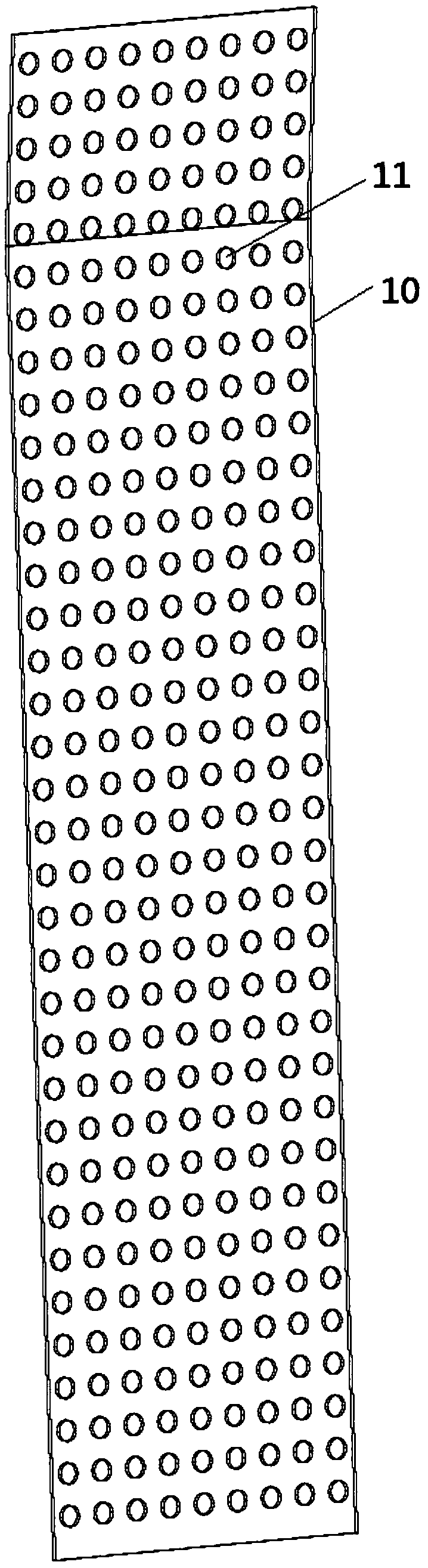

[0021] refer to image 3 , on the basis of Embodiment 1, electric heating tubes 5 are arranged on the installation insulation layer 6 opposite to the protective plate 10, and the upper ends of the electric heating tubes 5 are all protruded outwards to be provided with electric poles 4, and the protective plate 10 Cooperating with the electric heating tube 5, a number of uniform heat dissipation holes 11 are uniformly arranged, and the protection plate 10 is uniformly heated through the uniform heat dissipation holes 11, so that the spring is uniformly transformed, and the internal material is directionally transformed, and the shaping effect of the spring is strengthened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com