Hybrid 3D printing device and method used for building components

A technology of 3D printing and building components, which is applied in the direction of additive processing, process efficiency improvement, manufacturing tools, etc., can solve the problems of low printing efficiency and low strength of building components, and achieve easy printing, large printing coverage, and solution low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

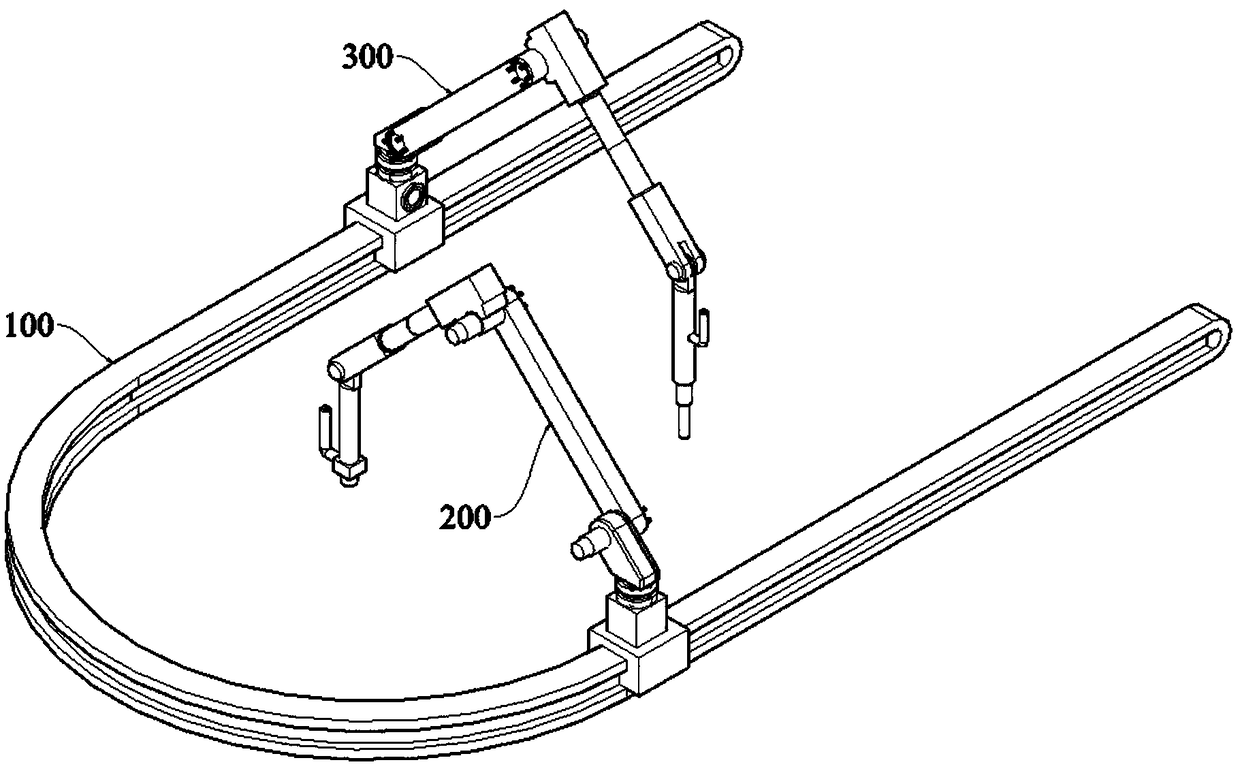

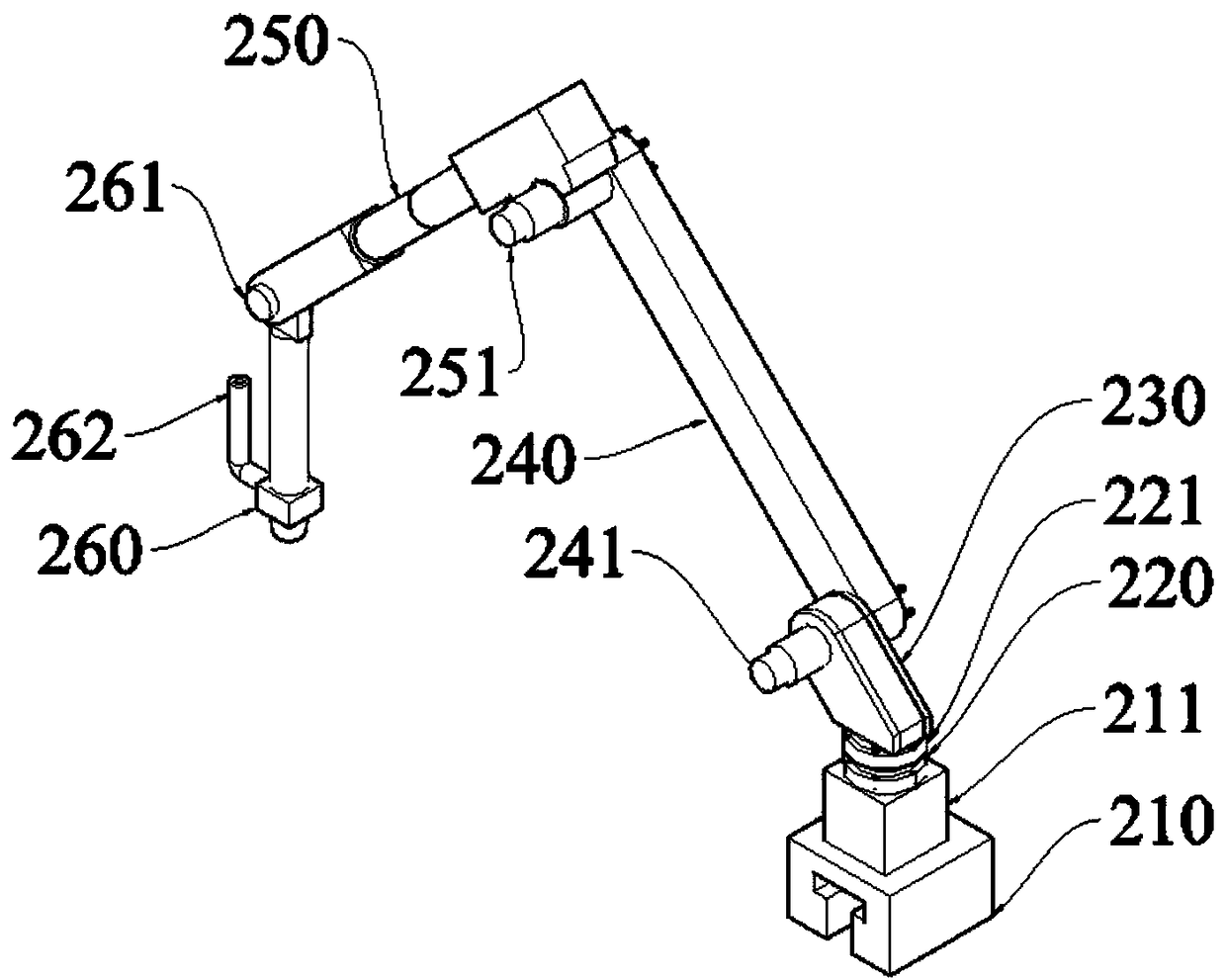

[0039] see Figure 1 to Figure 6 As shown, this embodiment provides a mixed material 3D printing device for building components, which will be combined below Figure 1 to Figure 6 The gist of the present invention is further described.

[0040] Such as figure 1 As shown, the mixed material 3D printing device includes a guide rail 100 , a main structure 3D printing mechanism 200 and a reinforcement structure 3D printing mechanism 300 .

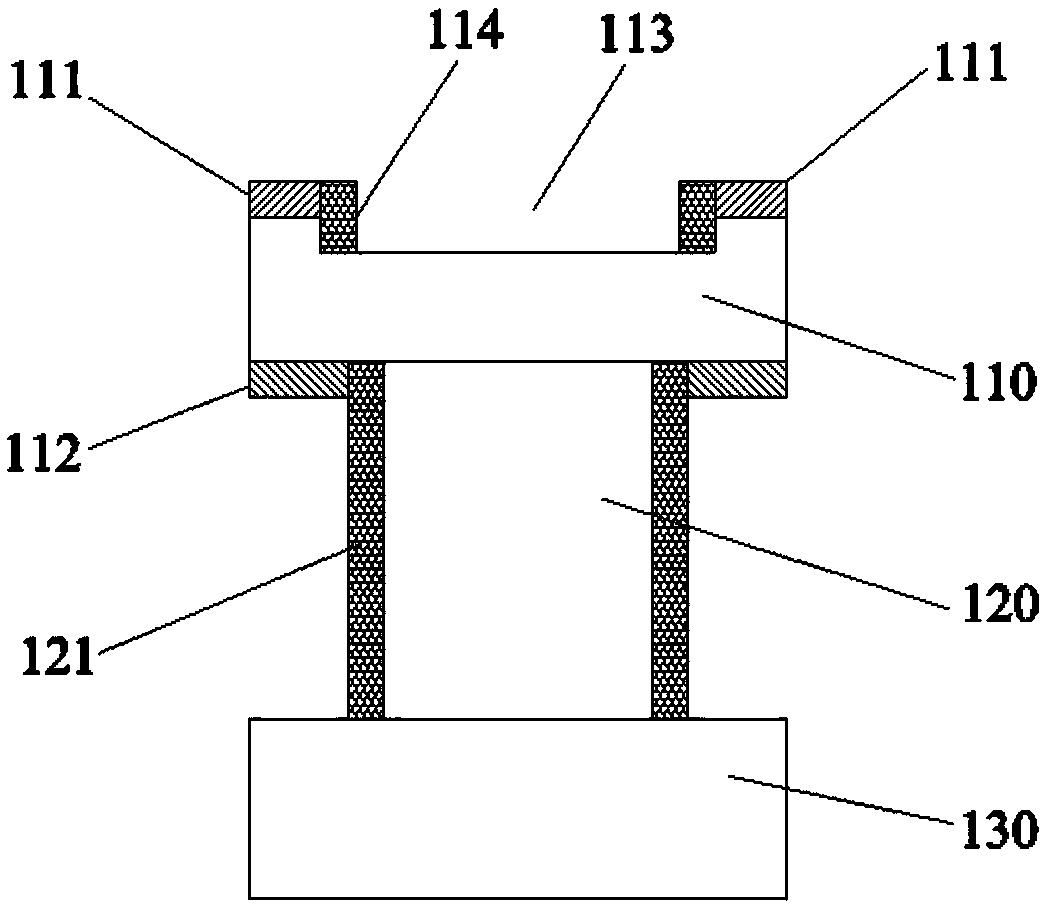

[0041] Such as figure 2 As shown, the guide rail 100 includes three parts: the upper track 110, the middle track 120 and the track base 130. These three parts form an I-shaped structure and are an integral structure; the track base 130 is fixed on the foundation surface; The side is provided with a rack guide rail 121; the upper and lower surfaces of the upper rail 110 are respectively provided with an upper slide rail 111 and a lower slide rail 112, and the upper surface of the upper rail 110 is provided with a rectangular groove 113, and ...

Embodiment 2

[0053] This embodiment provides a construction method for a mixed material 3D printing device for building components, combined below Figure 1 to Figure 6 The construction method is further described. This construction method comprises the steps:

[0054] Step 1, fix the guide rail 100 on the foundation surface, make the T-shaped groove of the sliding base 1 210 of the main structure 3D printing mechanism 200 snap on the upper slide rail 111 and the lower slide rail 112 of the guide rail 100, and put the gear 1. The second gear is engaged with the rack guide rail 1 121 and the rack guide rail 2 114 ; the sliding base 2 310 of the reinforced structure 3D printing mechanism 300 is buckled on the guide rail 100 . The guide rail 100 adopts a U-shaped guide rail 100, the main structure 3D printing mechanism 200, and the reinforced structure 3D printing mechanism 300 are set opposite to each other, and the printing work can be carried out at the same time without affecting each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com