Energy-saving coal screening device

A screening device, coal technology, applied in screening, loading/unloading, transportation and packaging, etc., can solve problems such as troubles, reduce the number of debugging and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

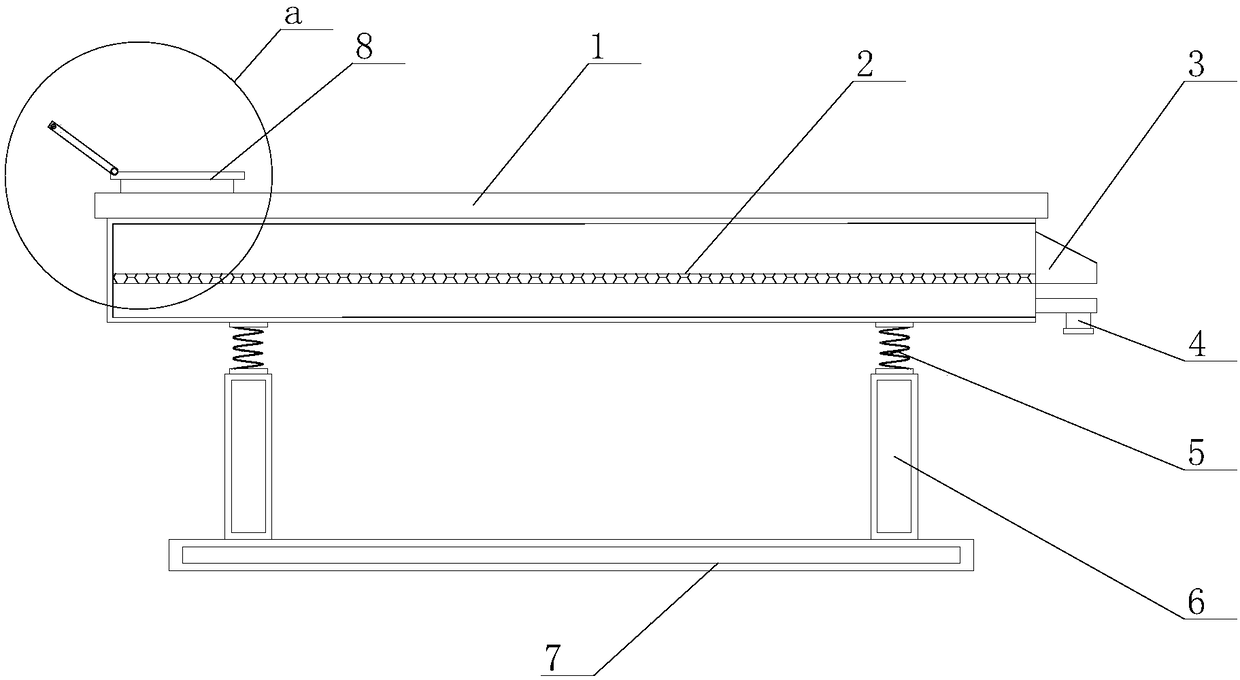

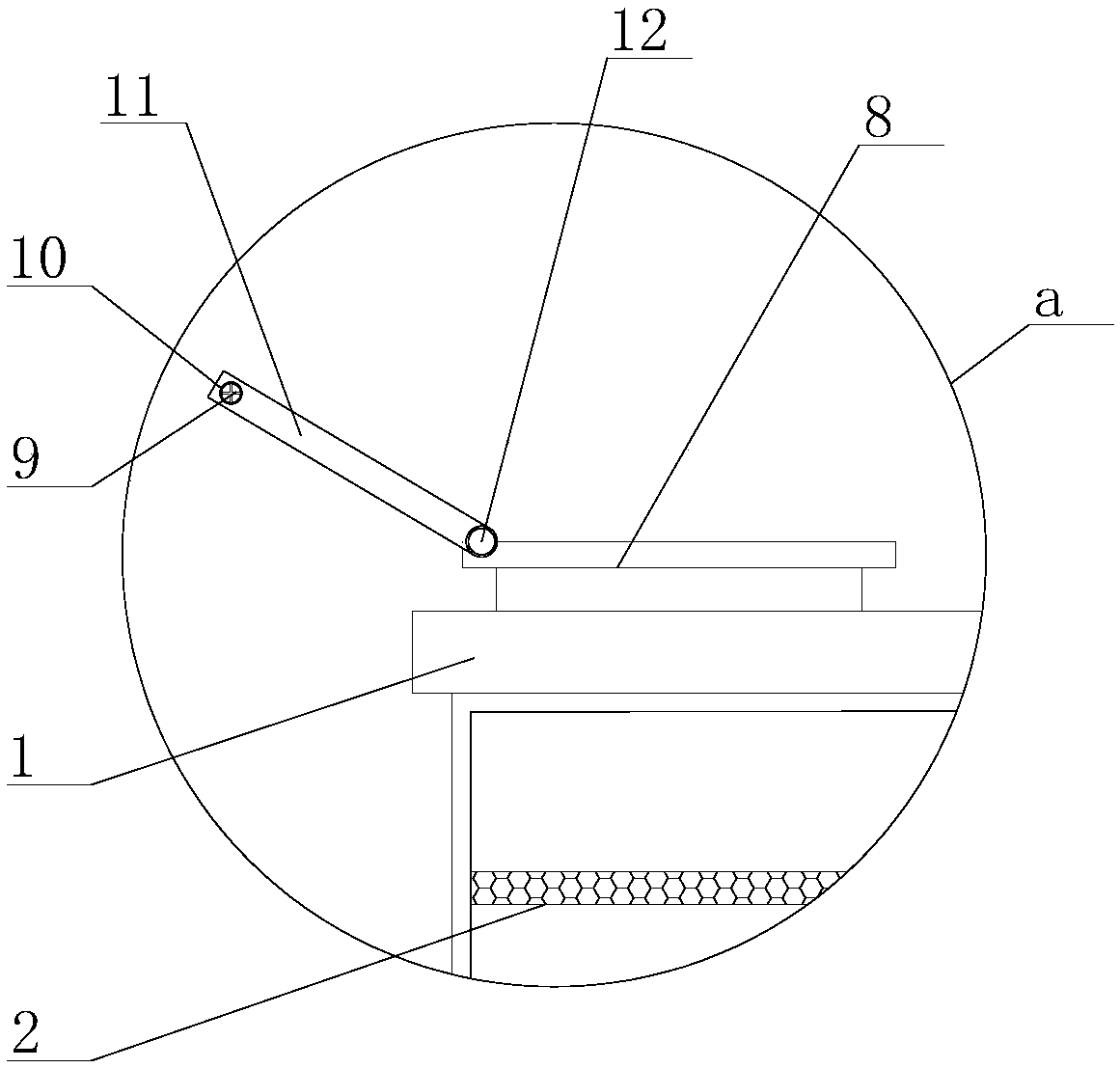

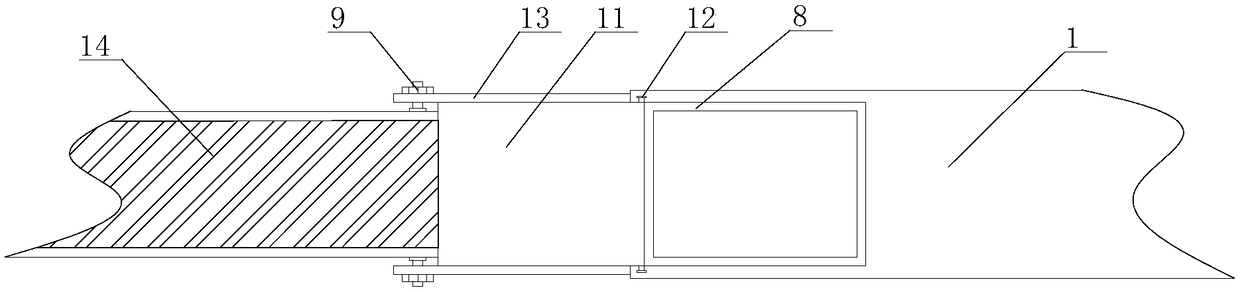

[0021] See Figure 1-3 , The present invention provides the following technical solutions: an energy-saving coal screening device, comprising an outer casing 1, the bottom end of the outer casing 1 is connected with a leg 6 through a spring 5, a base 7 is welded between adjacent legs 6, and the bottom of the base 7 The surface is glued with a rubber pad. One end of the upper surface of the outer shell 1 is integrally formed with a feeding port 8, the outer shell 1 is integrally formed with a discharge port 3 on the side different from the feeding port 8, and the outer shell 1 side is located at the outlet A slag discharge port 4 is integrally formed under the material port 3, a screen 2 is fixed by bolts at the inner middle position of the outer shell 1, and the screen 2 is a porous mesh structure with a mesh diameter of 3 mm, and the outer shell 1 A conveyor belt 14 is provided on one side of the slag discharge port 4 with a hollow cylindrical structure, and the inner diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com