Special partitioning switch lifting device

A hoisting device and isolating switch technology, used in hoisting devices, portable hoisting devices, etc., can solve the problems of difficult to determine construction time, huge workload, and large crane footprint. The effect of a small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

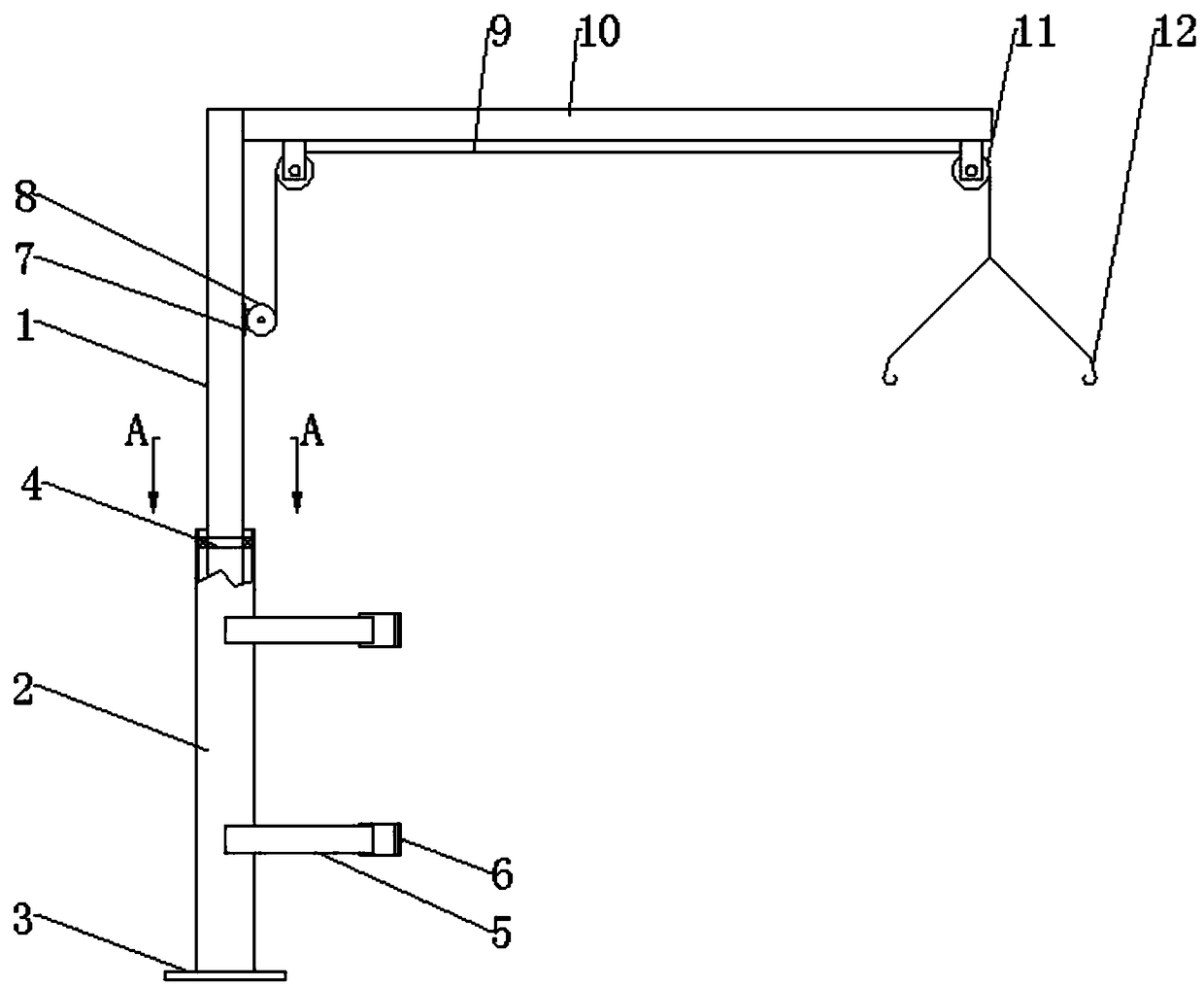

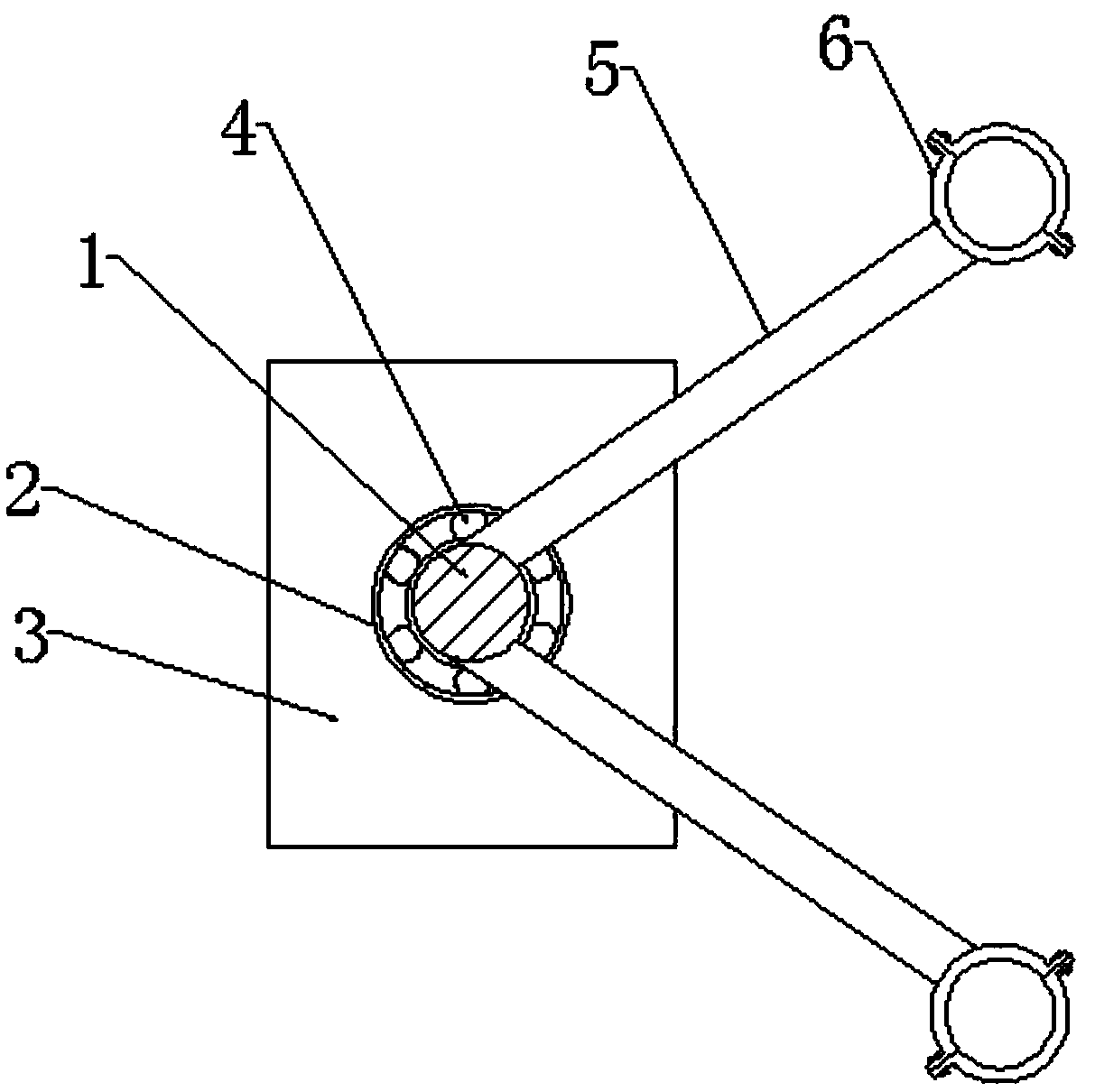

[0015] Such as figure 1 , figure 2 As shown, the special lifting device for the isolating switch includes a column, and the column is composed of a support rod 1, a support tube 2 sleeved at the bottom of the support rod 1 and a support seat 3 welded at the bottom end of the support tube 2. The support rod 1 and Bearings 4 are connected between the support tubes 2; two groups of electric pole cable-stays arranged up and down and each group arranged left and right are welded on the side wall of the support tube 2. Composition; motor 7 is installed on support bar 1, winding wheel 8 is installed at the output shaft end of motor 7, and suspension rope 9 is wound on winding wheel 8, and horizontal boom 10 is welded on the top of support bar 1, and the bottom of boom 10 has two front and rear sides. Pulleys 11 are respectively installed at the two ends of the suspension rope 9. The free ends of the suspension rope 9 bypass each pulley 11 from the back to the front and hang down fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com