Anti-floating pile raft structure of pipe pile

An anti-floating pile and pipe pile technology, applied in the direction of foundation structure engineering, sheet pile wall, protection device, etc., to achieve the effect of improving bearing performance, reducing settlement and increasing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

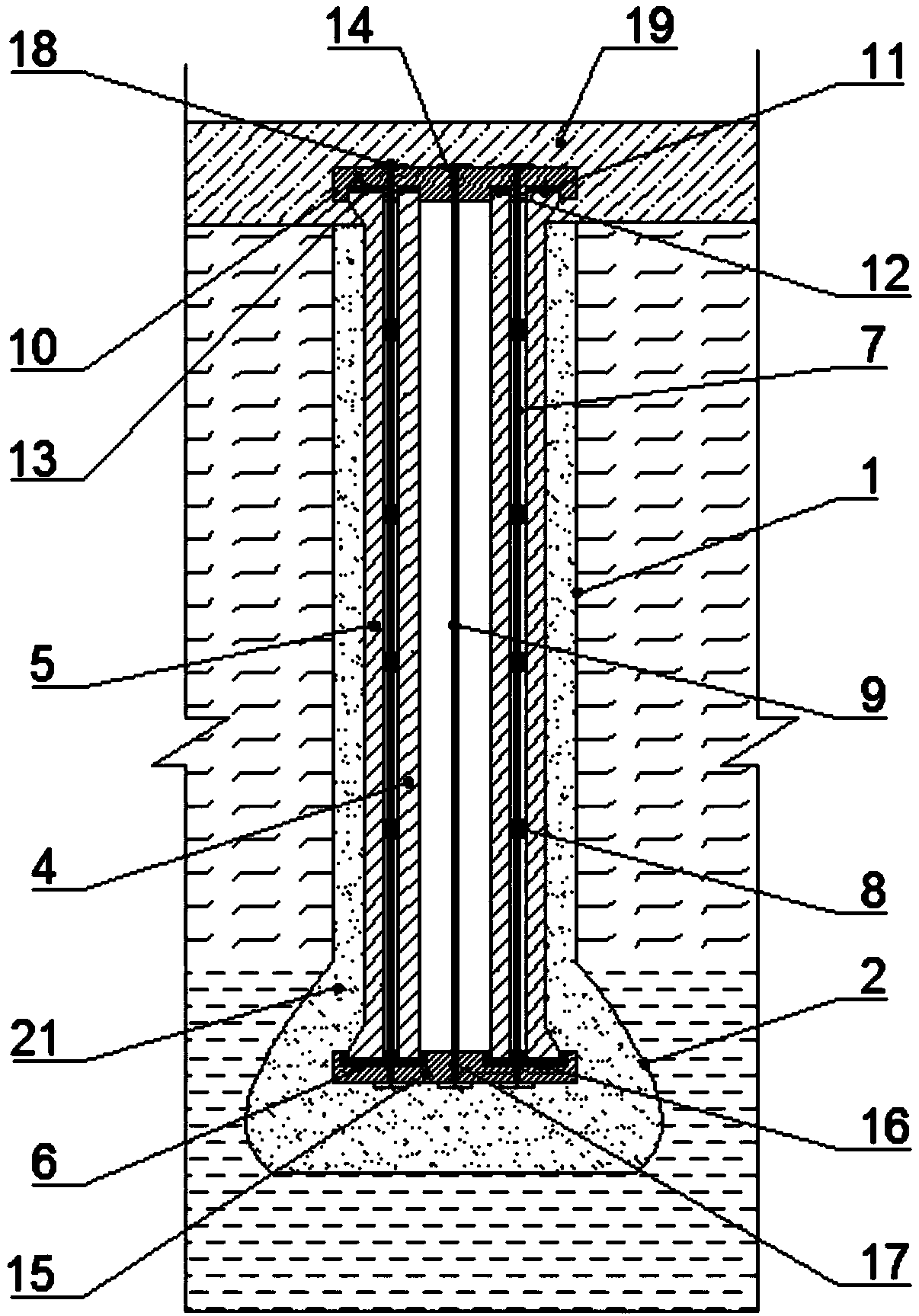

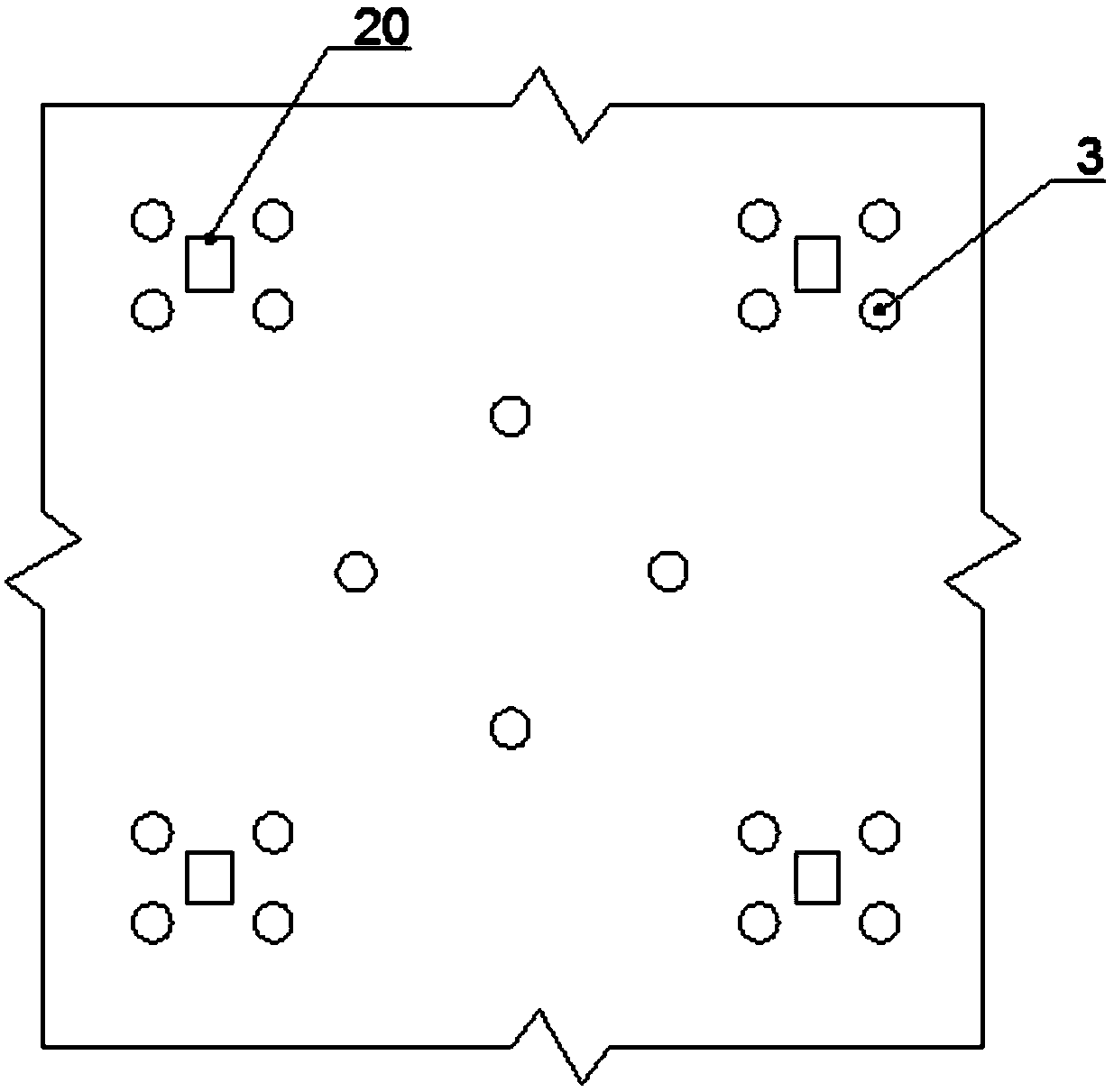

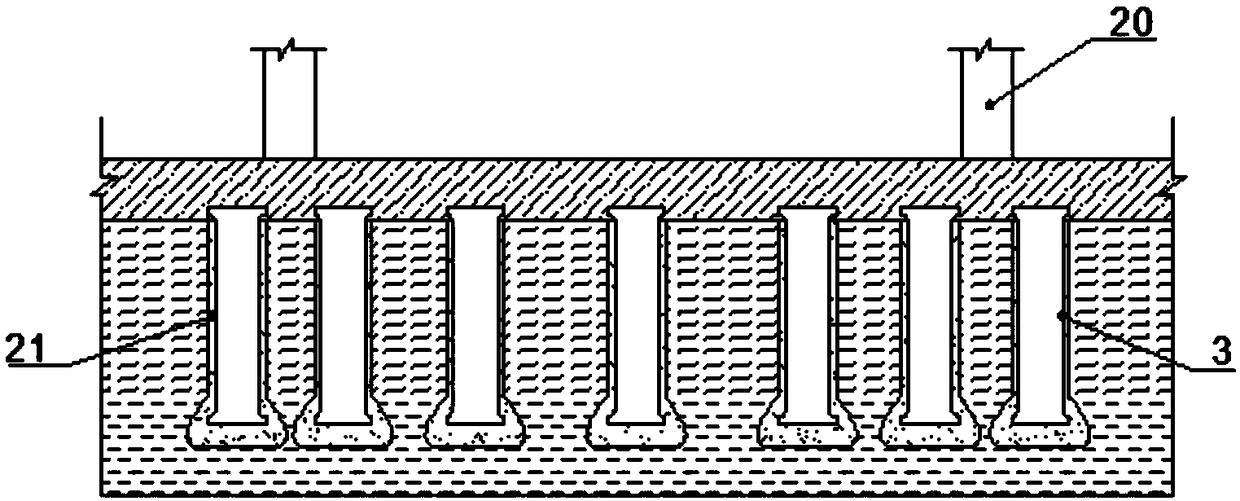

[0033] Such as Figure 1 to Figure 3 As shown, a pipe pile anti-floating pile raft structure includes a pile hole 1, an enlarged pile end 2 is arranged at the bottom of the pile hole 1, a pipe pile 3 is arranged in the pile hole 1, and a gap between the inner wall of the pile hole 1 and the outside of the pipe pile 3 The distance between the pile hole 1 and the pipe pile 3 is filled with a slurry solid 21, the material used for the slurry solid 21 is concrete, and the pipe pile 3 includes an inner cylinder 4 and an outer cylinder 5 distributed from the inside to the outside. The bottoms of the inner cylinder 4 and the outer cylinder 5 are connected by a sealing cap 6, a number of first anchor cables 7 are arranged between the inner cylinder 4 and the outer cylinder 5, and a plurality of annular rings 8 are arranged on the first anchor cables 7, and inside the inner cylinder 4 Several second anchor cables 9 are provided, the top end plate 10 is arranged on the top of the pipe p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com