Treatment method for cracking and seepage of basement bottom plate

A basement floor and treatment method technology, which is applied in protection devices, buildings, infrastructure engineering, etc., can solve the problems of basement floor cracking and water seepage, and achieve the effects of preventing water seepage from cracking again, enhancing the anti-floating ability, and avoiding floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

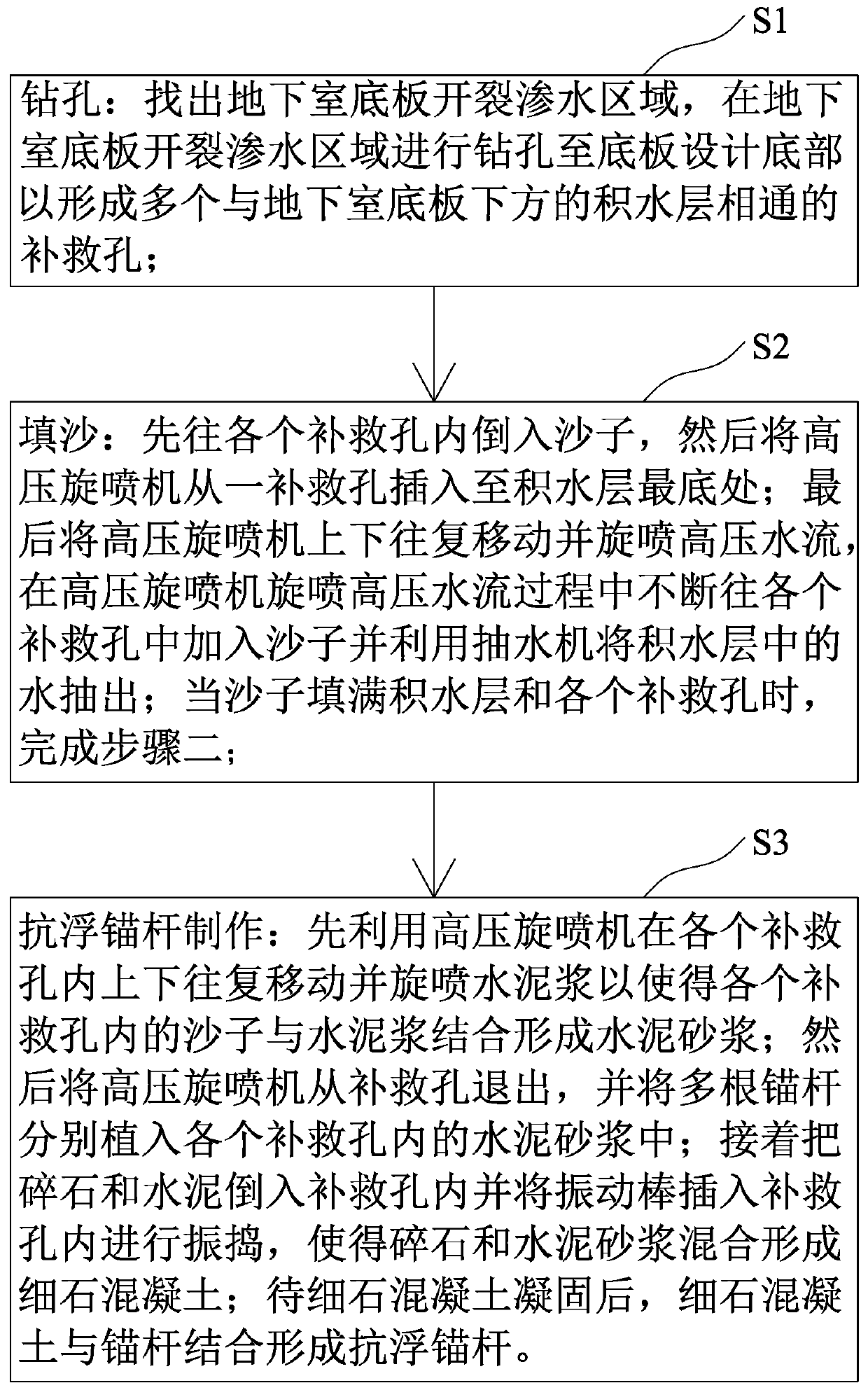

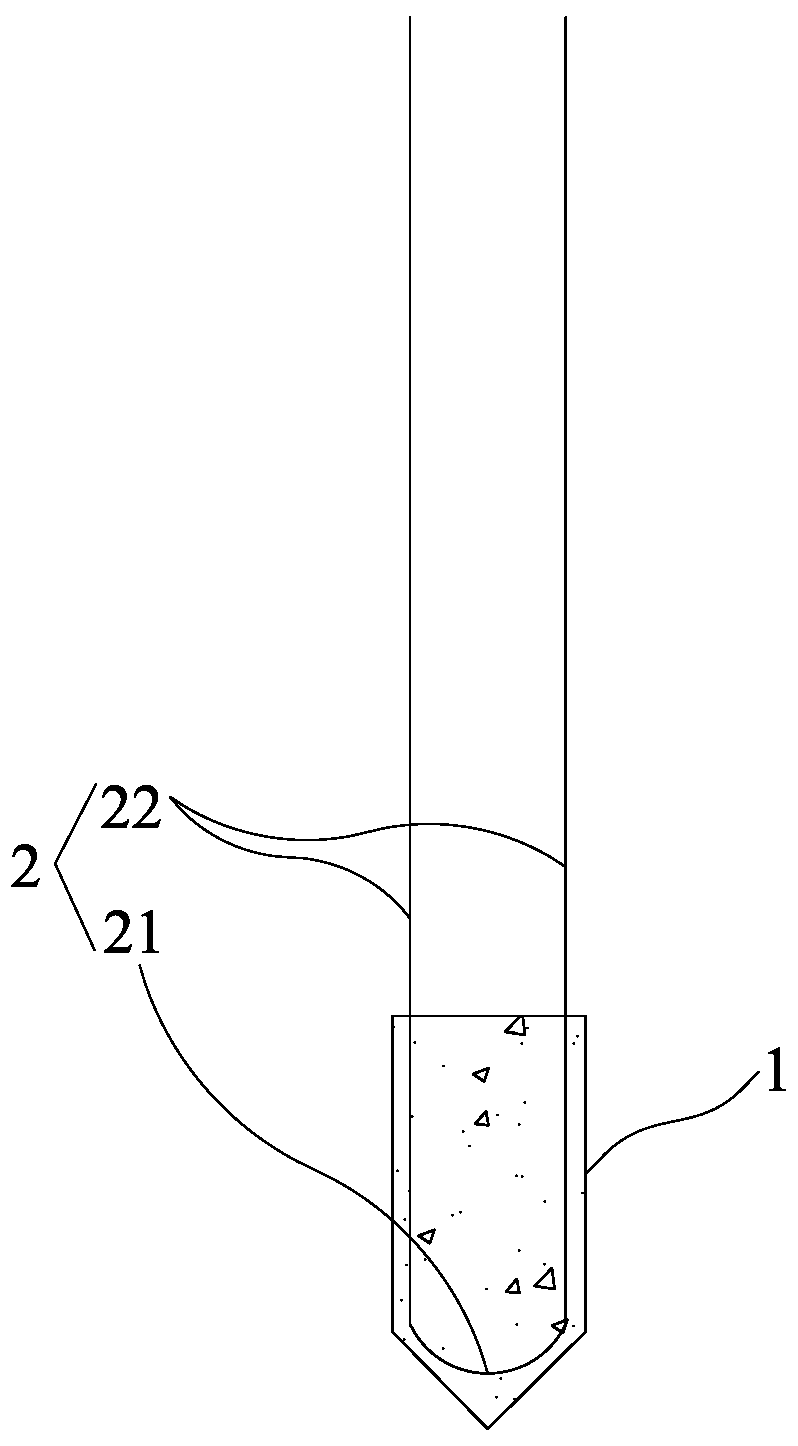

[0027] like figure 1 As shown, the present invention discloses a treatment method for basement floor cracking and water seepage, which includes the following steps:

[0028] Step 1 S1, drilling: find out the cracked water seepage area of the basement floor, drill holes in the cracked water seepage area of the basement floor to the bottom of the base plate design to form a plurality of remedial holes communicating with the water accumulation below the basement floor; wherein the remedial holes The diameter of the hole is 10~15 cm; the distance between adjacent remedial holes is 3 meters;

[0029] Step 2 S2, sand filling: first pour sand into each remedial hole, then insert the high-pressure rotary sprayer from a rescue hole to the bottom of the water layer; finally move the high-pressure rotary sprayer up a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com