Electromechanical automatic leveling rotating base

A technology of automatic leveling and rotating the base, applied in the direction of supporting machines, mechanical equipment, machine tables/supports, etc., can solve the problems of low leveling accuracy, unstable rotation, cumbersome operation, etc., to achieve simple and convenient leveling operation, improve Bearing capacity, effect of reducing bending loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

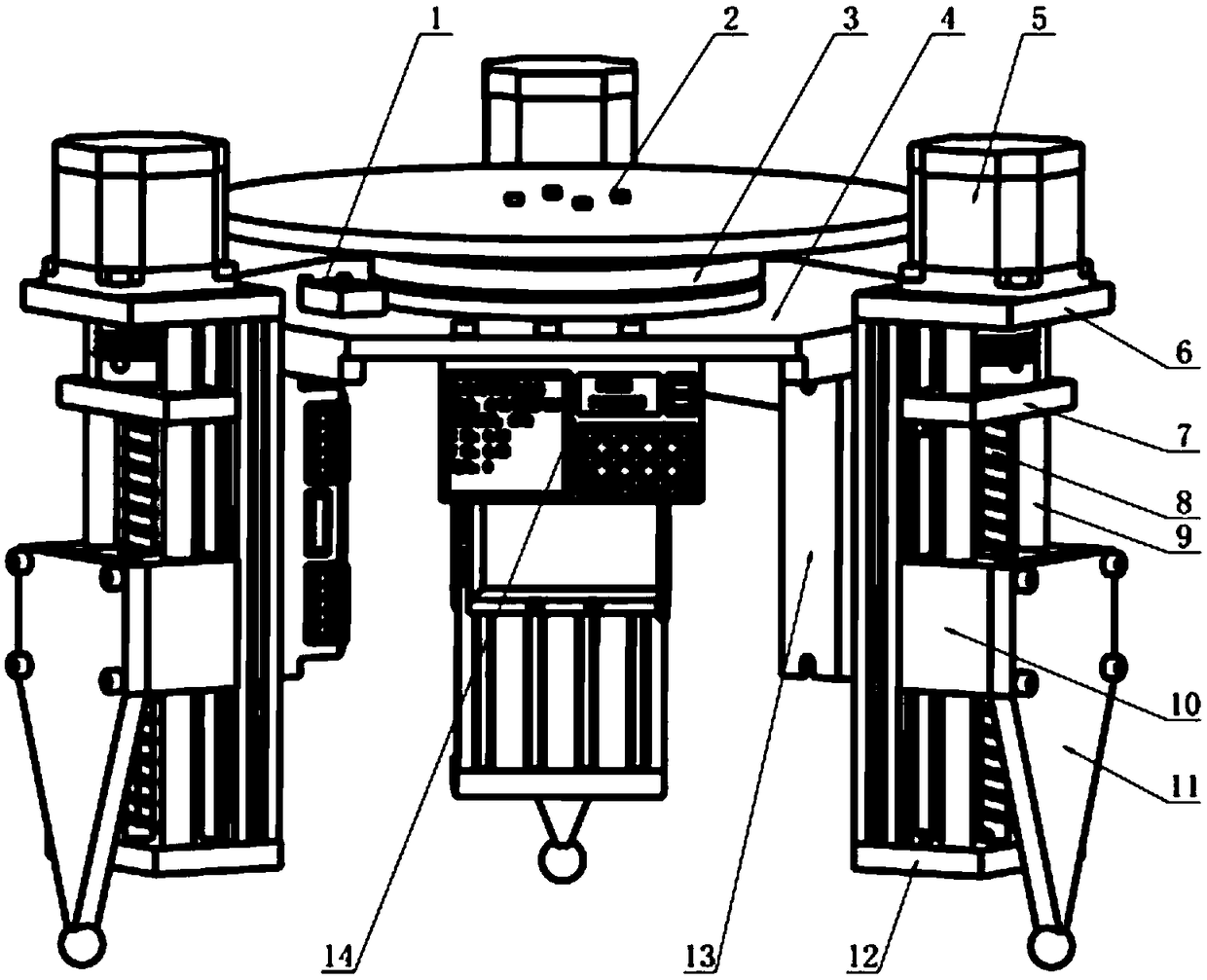

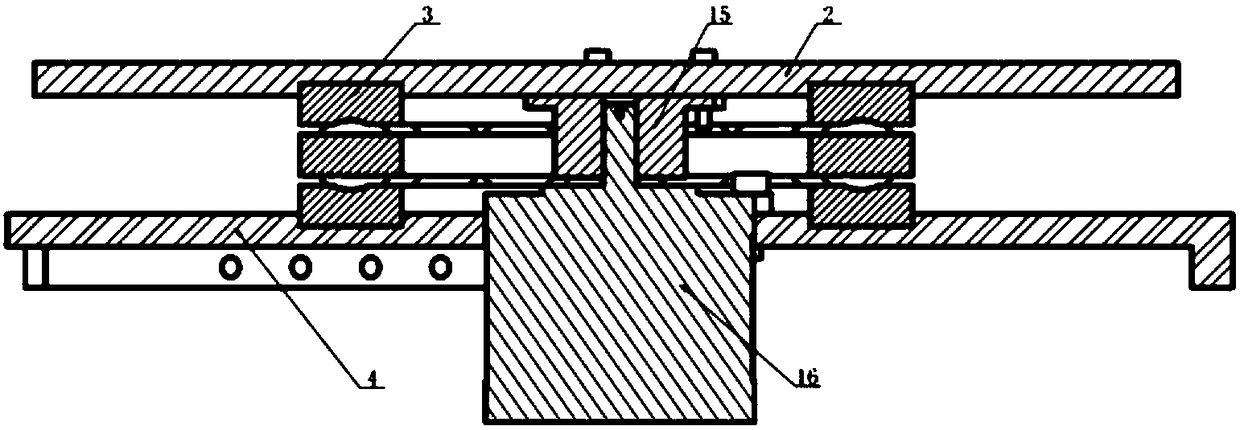

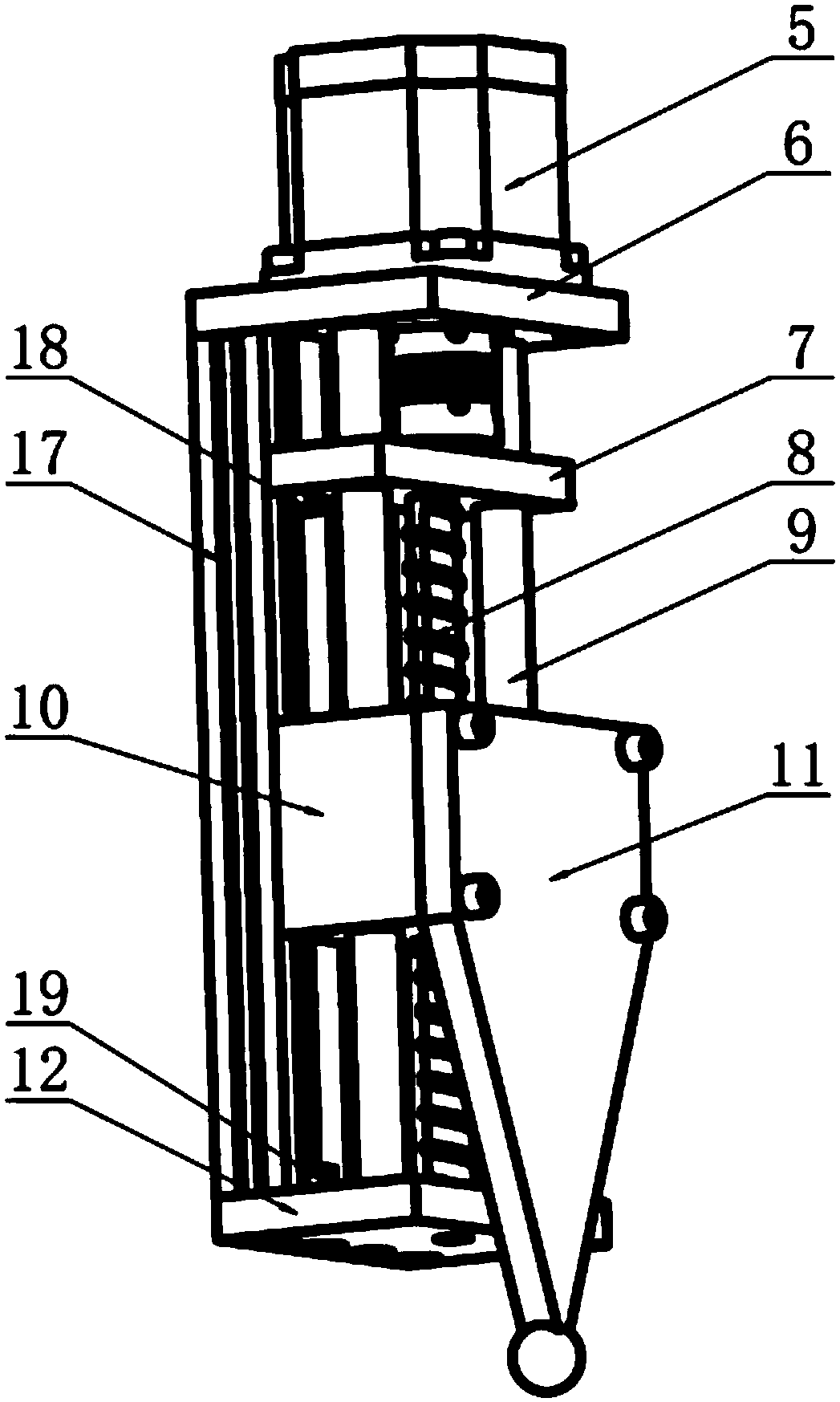

[0020] combine Figure 1 to Figure 5 , an electromechanical self-leveling rotating base, including an upper plate 2, a connecting plate 4, a rotating mechanism, a level sensor 1, a control display unit 14, a first motor driver, three second motor drivers 13, and three sets of leveling supports Mechanism; the upper plate 2 is arranged in parallel directly above the connecting plate 4, the rotating mechanism is arranged between the upper plate 2 and the connecting plate 4, three sets of leveling support mechanisms are symmetrically fixed on the outer wall of the connecting plate 4, and the first motor driver is fixed On the bottom surface of the connecting plate 4, the first motor driver is connected to the rotating mechanism, and a second motor driver 13 is fixedly connected on each group of leveling support mechanisms; the level sensor 1 is fixed on the top s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com