Integral static load test method of deflector for missile launching

A static load test and missile launch technology, which is applied in the testing of machine/structural components, instruments, and mechanical components, etc., can solve problems such as the unsatisfactory pressure method of the test press, and achieve reliable and stable test data and product quality. The effect of low risk and low trial cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

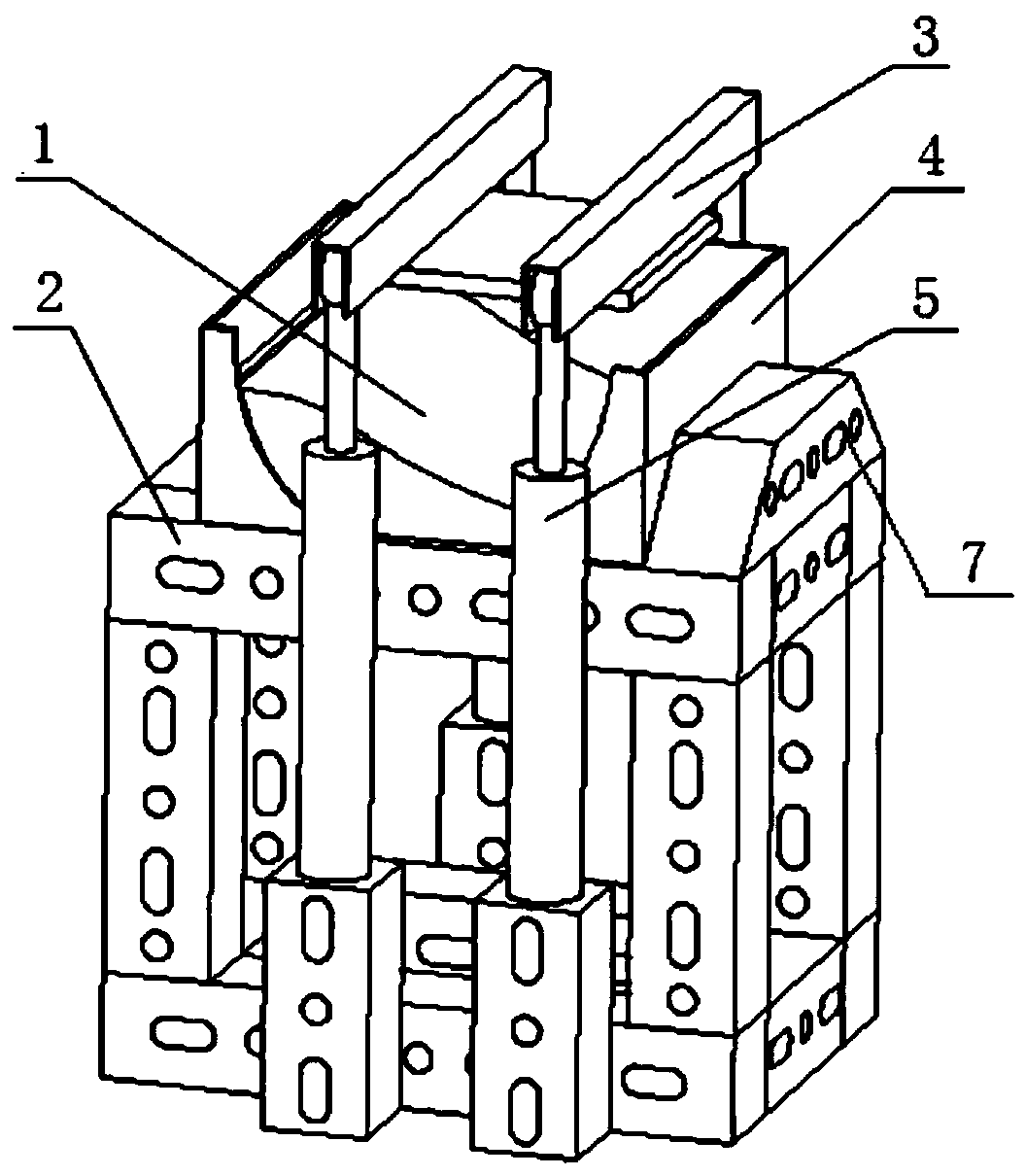

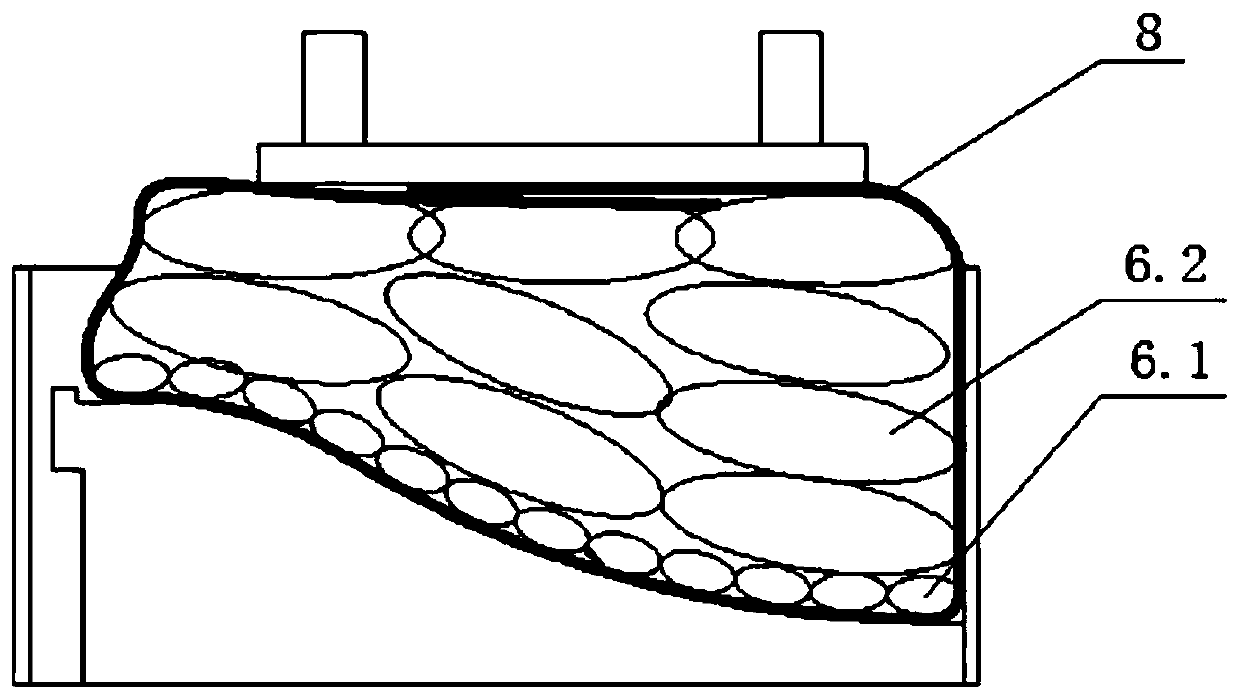

[0033] A certain type of deflector is a unilateral type of deflector structure (see Figure 5 ), the profile is a double inflection point arc surface, the forward projection size is 1200×1200mm, and the height is 370mm. It is required to have an overall bearing capacity of 40t. The test process must not damage the non-metallic surface. The test method includes the following steps:

[0034] 1) Install a strain sensor on each of the fourteen measurement points on the bottom surface of the deflector 1 to be tested, respectively bond the five vertical pull wires of the displacement sensor to the five measurement points on the bottom of the deflector to be tested, and all the strain sensors The signal line of the displacement sensor is jointed with the signal line of the displacement sensor and connected to the data collector together;

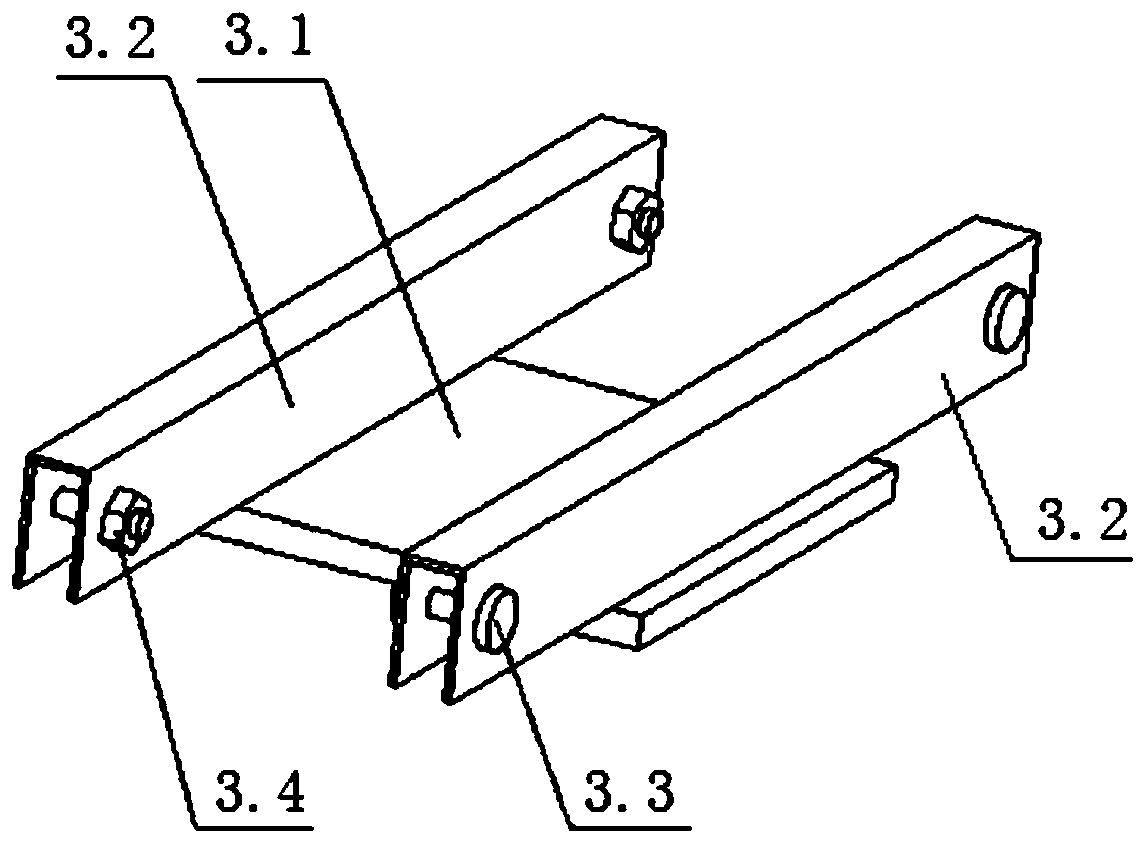

[0035]2) Assemble the deflector 1 to be tested after step 1) into the frame 4 on the top of the test bracket 2, and the assembly state of the defl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com