Compaction-method triaxial sample preparation device and method

A triaxial sample and preparation device technology, applied in the preparation of test samples, measuring devices, sampling, etc., can solve the problem of uneven compaction force, large gears and racks, and reduce friction between samples and sample preparation molds To avoid problems such as force, to achieve the effect of reliable sample preparation process and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

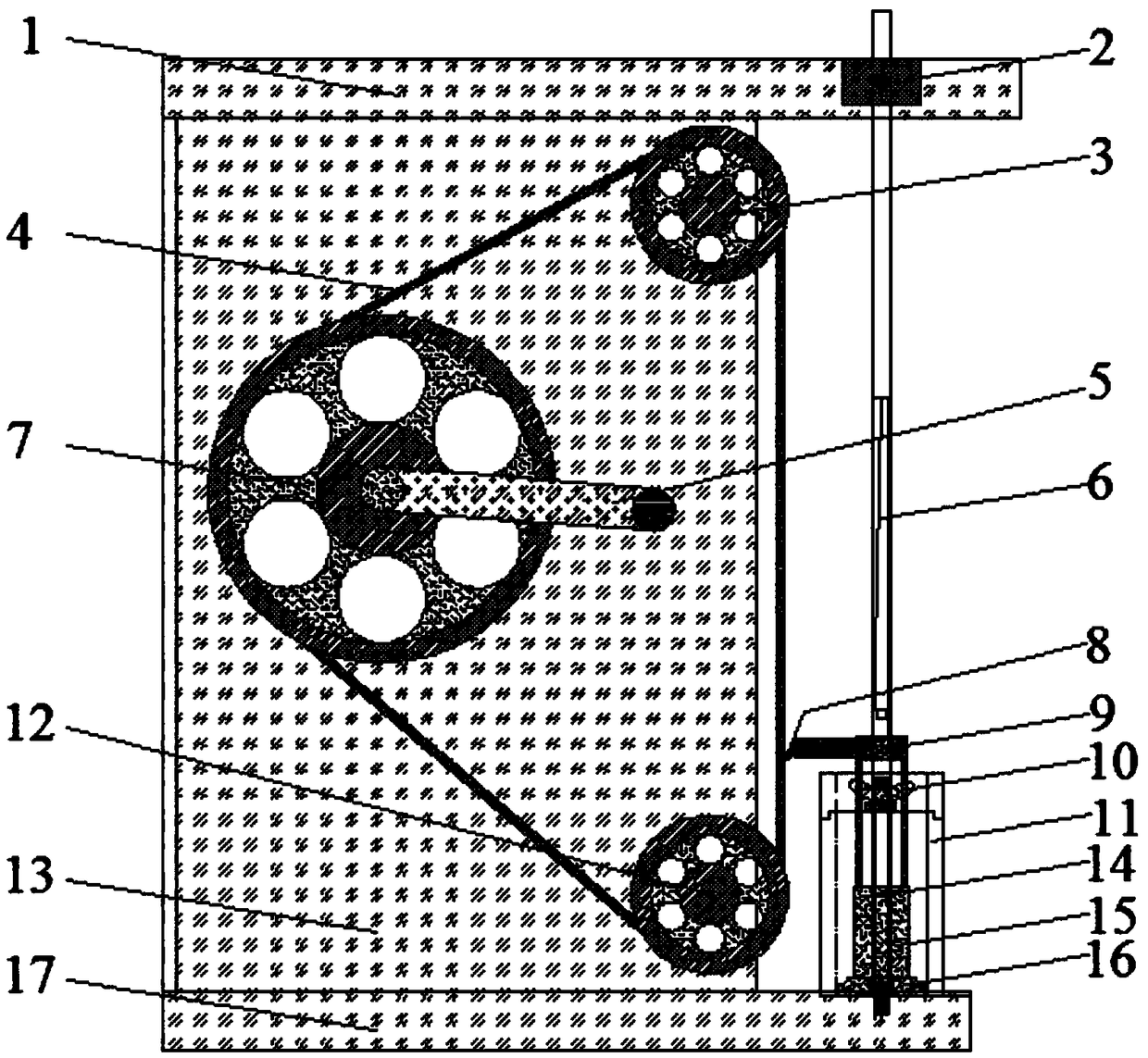

[0034] The present invention will be further described in detail below in conjunction with specific embodiments.

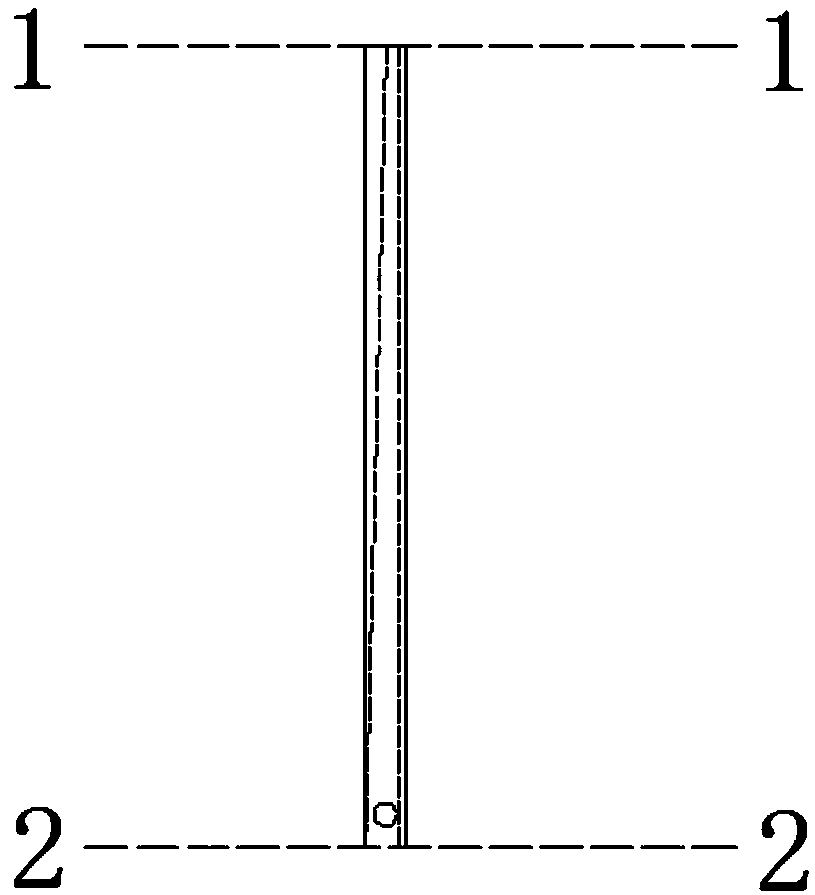

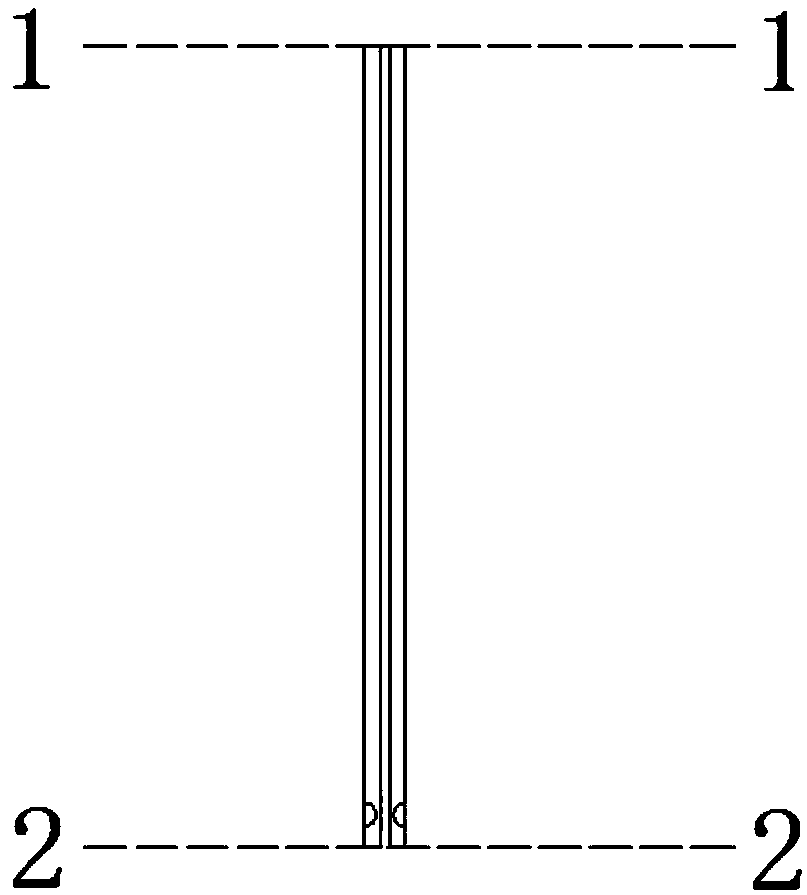

[0035] Such as Figure 1-Figure 14 As shown, a compaction method triaxial sample preparation device of the present invention includes a fixed frame 13 fixed on the base 17, a power supply device and a sample striking device respectively arranged on the fixed frame 13 and the base 17. The power supply device comprises a transmission wheel 7, an upper driven wheel 3 and a lower driven wheel 12 fixed on the fixed frame 13 in a triangular distribution, and the transmission wheel 7, the upper driven wheel 3 and the lower driven wheel 12 are connected as a whole by a transmission belt 4, and the The transmission belt 4 is fixedly connected with a lifting rod 8, the transmission wheel 7 is provided with a rocking handle 5, and the top of the fixed frame is a fixed frame top plate 1, and its bottom surface is higher than the top of the upper driven wheel 3;

[0036] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com