An apparatus for cooling and energizing a corona region of a plasma generator

A plasma and generator technology, applied in the field of plasma generators, can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

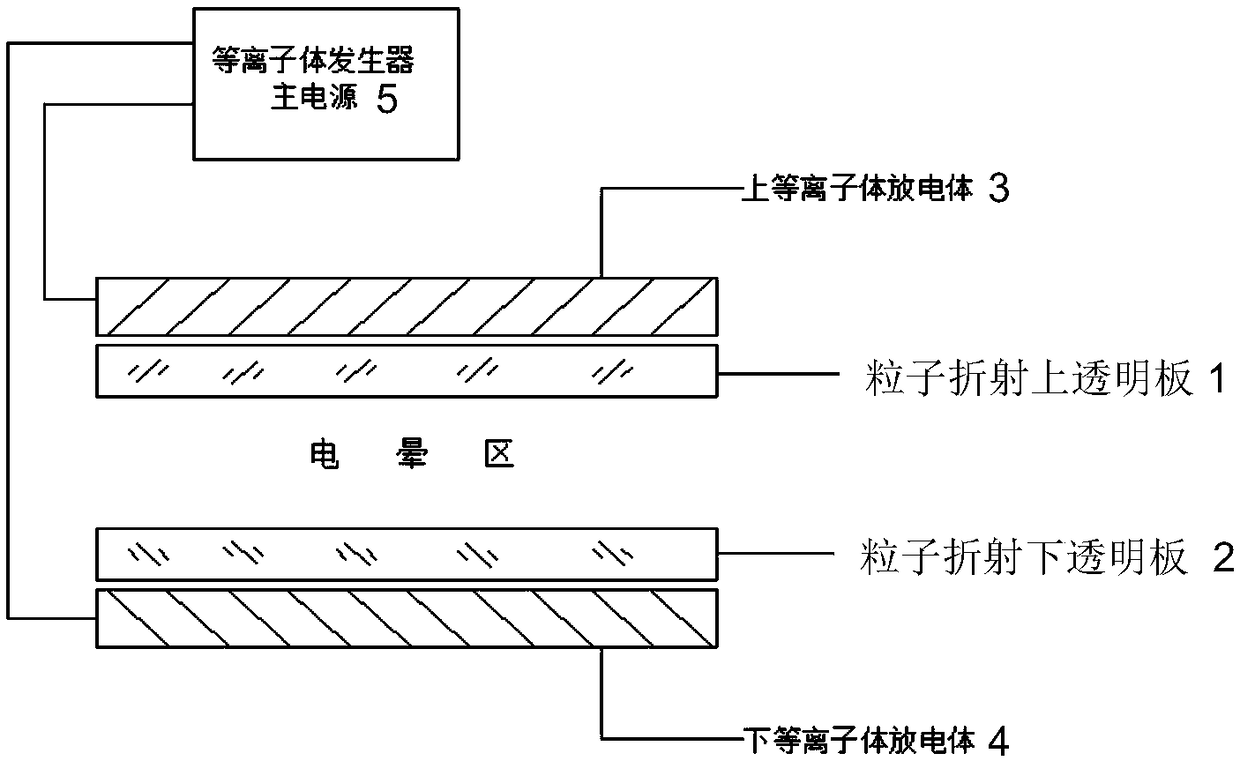

[0020] like figure 1 As shown, a device for cooling down and increasing energy in the corona region of a plasma generator, the device includes an upper transparent plate 1 for particle refraction and a lower transparent plate 2 for refraction of particles, and the upper transparent plate 1 for particle refraction is arranged on Below the plasma discharge body 3, the particle-refracting lower transparent plate 2 is arranged above the lower plasma discharge body 4; a space for repeated vibration of particles is formed between the particle-refracting upper transparent plate and the particle-refracting lower transparent plate. The upper plasma discharge body 3 and the lower plasma discharge body 4 are connected to the main power supply 5 of the plasma generator.

[0021] The upper transparent plate for particle refraction and the lower transparent plate for particle refraction are transparent materials selected from one or more of plastic, silicate glass, natural fused quartz, art...

Embodiment 2

[0026] The plasma generator used at normal temperature and pressure, after adding the device of the present invention, makes the temperature of the original corona area drop from about 400°C to about 40°C-80°C, and the energy of the original particle beam will be increased by more than two times .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com