Horizontal lifting control system and method for header of intelligent harvester

A horizontal lift and control system technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve problems such as low work efficiency, blockage, and large engine radiation noise of harvesters, so as to meet the production process requirements and reduce Effect of radiation noise and improvement of work efficiency

Pending Publication Date: 2018-12-28

JIANGSU AGRI ANIMAL HUSBANDRY VOCATIONAL COLLEGE

View PDF11 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional header requires the driver to constantly manipulate the adjustment handle to adjust the height of the header through visual observation according to factors such as the terrain and the harvested crops; manual manual adjustment has its inherent defects, and the adjustment accuracy and real-time performance are very important. Uncertainty, it is difficult to achieve the consistency of stubble height during harvesting operation;

At the same time, it is easy to stick to the soil during cutting and cause blockage, manual cleaning is troublesome, the engine radiation noise of the harvester is large, and cannot be adjusted, the speed synchronization requirements of the conveyor belt cannot meet the production process requirements, the height of the header needs to be controlled manually, and the work efficiency is low.

The existing technology cannot effectively remove the noise of the mechanical operating parts during operation, and cannot improve the performance of the operating equipment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

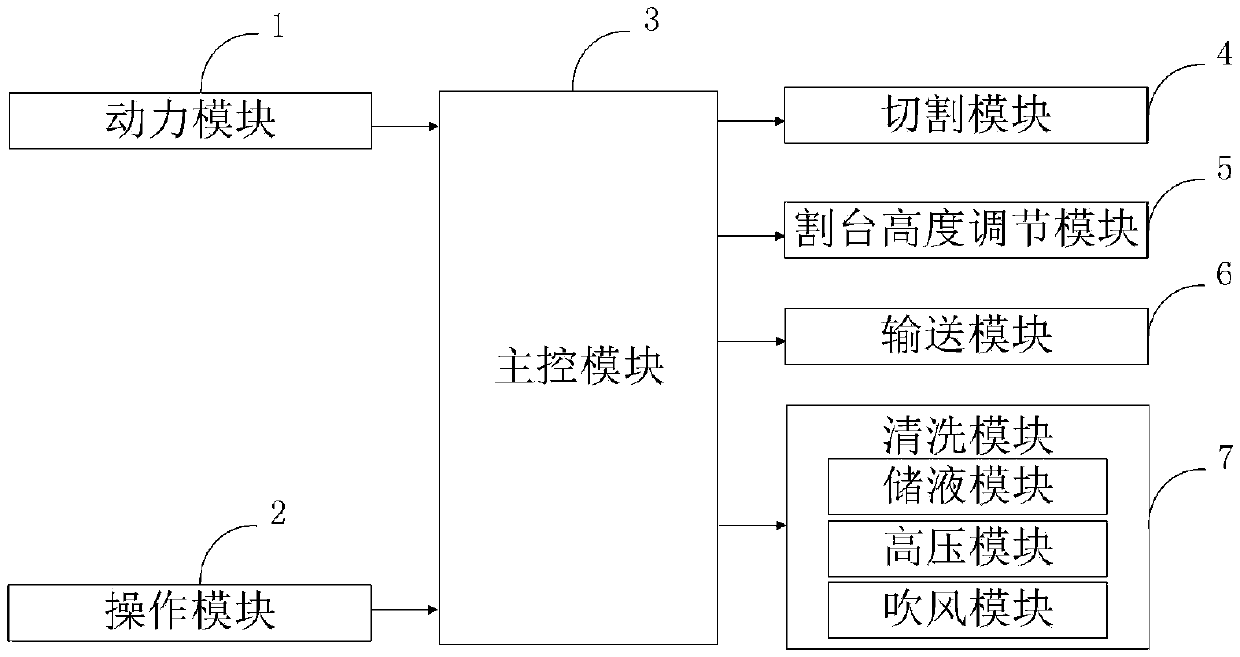

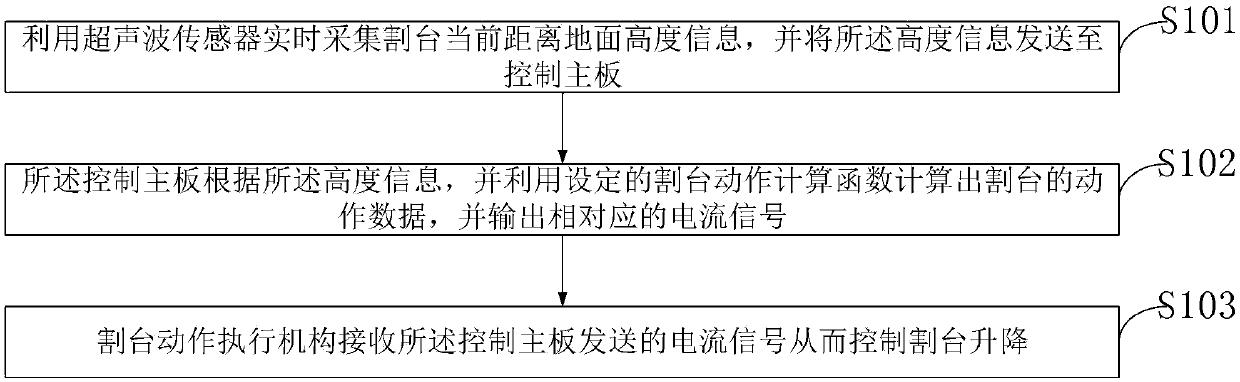

The invention belongs to the technical field of harvesters, and discloses a horizontal lifting control system and method for a header of an intelligent harvester. The horizontal lifting control systemfor the header of the intelligent harvester comprises a power module, an operating module, a main control module, a cutting module, a header height adjustment module, a conveying module and a cleaning module. According to the horizontal lifting control system, the harvester can automatically adjust the height steadily and in real time at a set speed through the header height adjustment module according to a topographical change of the field, so that the header is kept a certain distance away from the floor to guarantee the safety of the harvester and the harvesting quality and make up the shortcomings of low manual adjustment instantaneity, low adjustment precision and the like; and meanwhile, sludge on a blade of the header can be flushed more quickly and conveniently through the cleaning module, so as to avoid cutting blockage and a header fault.

Description

technical field The invention belongs to the technical field of harvesters, and in particular relates to an intelligent harvester header horizontal lifting control system and method. Background technique At present, the existing technologies commonly used in the industry are as follows: Harvester It is an integrated machine for harvesting crops. Harvesting, threshing and concentrating the grains into the storage bin at one time, and then transporting the grains to the transport vehicle through the conveyor belt. Manual harvesting can also be used to spread the stalks of rice, wheat and other crops in the field, and then use grain harvesting machinery to pick up and threshing. Crop harvesting machinery for harvesting grains and stalks of cereal crops such as rice and wheat. Including harvesters, windrowers, balers, grain combines and grain threshers, etc. Grain harvesting machinery is developed on the basis of various harvesting and threshing tools. However, the traditi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A01D41/14

CPCA01D41/141A01D41/145

Inventor 王国强金濯段修军管远红李晶崔勇

Owner JIANGSU AGRI ANIMAL HUSBANDRY VOCATIONAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com