Garden lawn fallen leaf cleaning device

A technology for cleaning device and lawn, applied in lawn growth, gardening, grain treatment and other directions, can solve the problems of leaf wrinkle, low use efficiency, waste of space, etc., and achieve the effect of reducing occupied space, good effect and small occupied space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

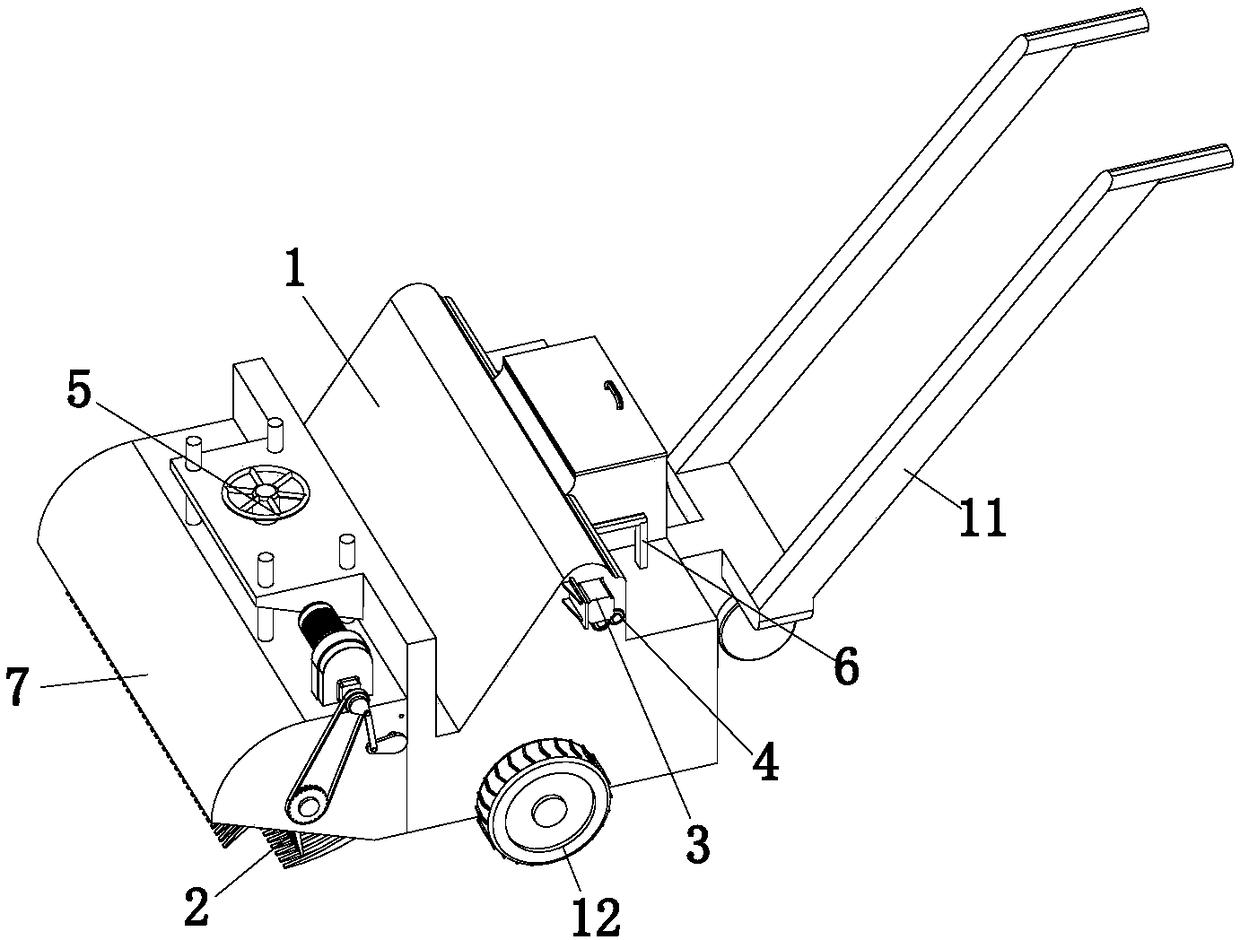

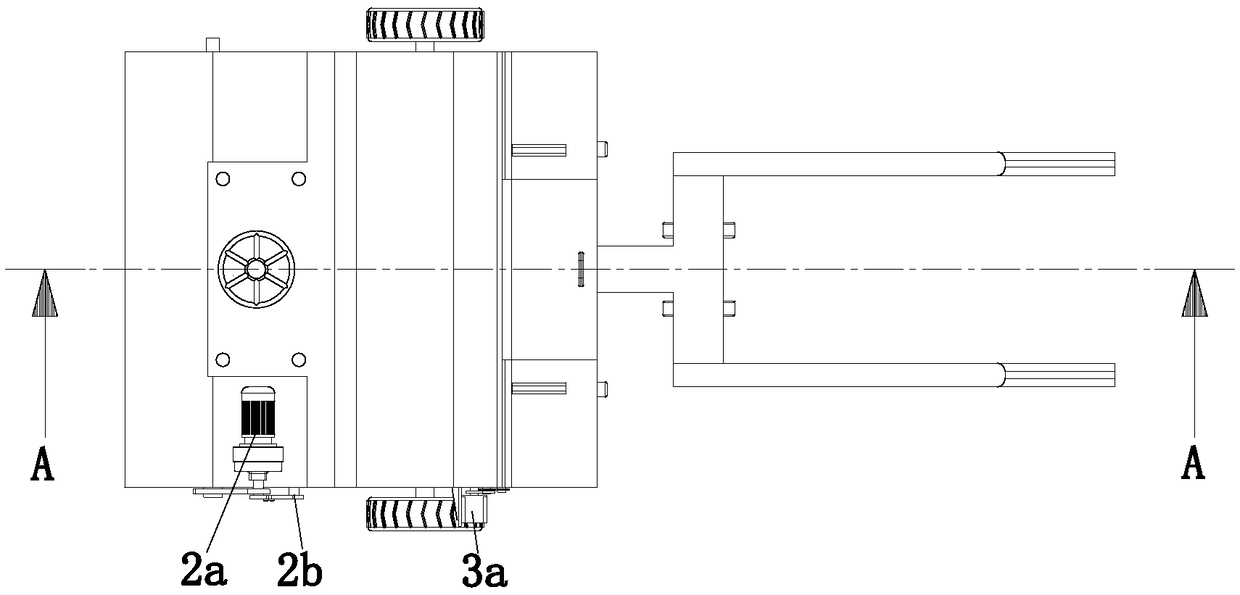

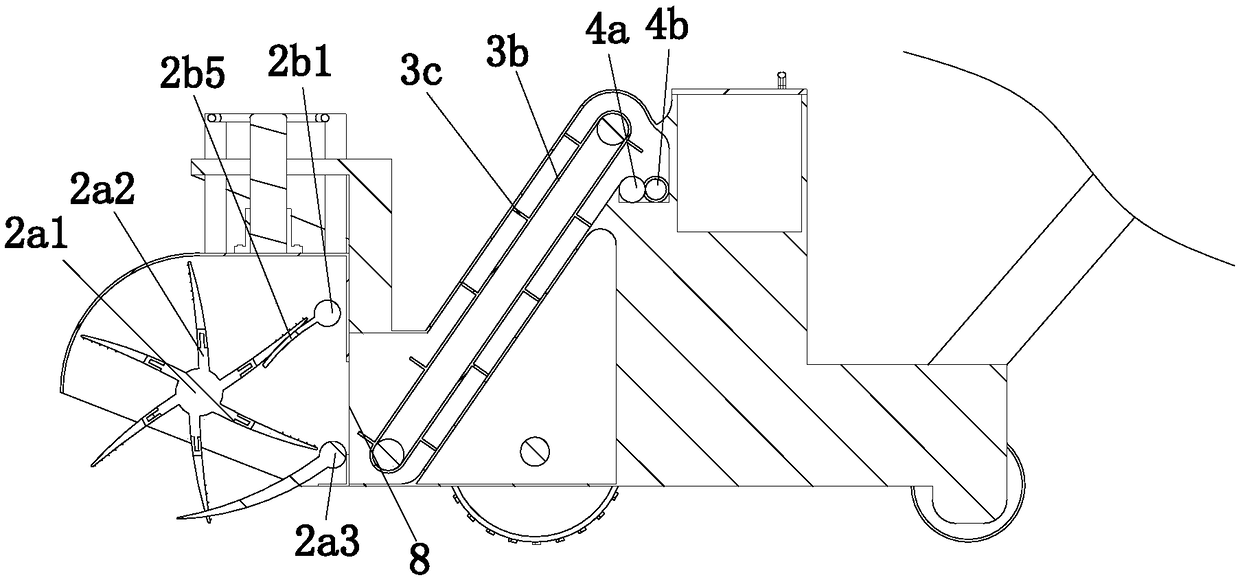

[0037] A garden and lawn leaf cleaning device, comprising a housing 1, a collecting mechanism 2, a conveying mechanism 3, a crushing mechanism 4, an adjusting mechanism 5 and a compacting mechanism 6, the upper end of the housing 1 is provided with a front shell 7, the front Both the shell 7 and the shell 1 are provided with a connecting port 8 for communicating the two, the collection mechanism 2 is installed on the lower end of the front shell 7, and the front shell 7 and the shell 1 are connected by an adjustment mechanism 5, so The conveying mechanism 3 is located between the collecting mechanism 2 and the crushing mechanism 4, and the rear end of the housing 1 is provided with two collecting chambers 9, both of which are located below the crushing mechanism 4, and the compacting mechanism 6 There are two, two compaction mechanisms 6 are respectively arranged in two collection chambers 9, the collection mechanism 2 includes a collection assembly 2a and a blocking assembly 2...

Embodiment 2

[0047] The collection assembly 2a includes a collection shaft 2a1, several mounting plates 2a2 and a shovel shaft 2a3, both ends of the collection shaft 2a1 are rotatably connected to the front shell 7, and several Mounting plate 2a2, the upper end of the front shell 7 is provided with a drive motor 2a4, the front end of the drive motor 2a4 is provided with a reducer 2a5, the output end of the reducer 2a5 is provided with a drive gear 2a6, and the collecting shaft 2a1 One end of the drive gear 2a7 is provided with a driven gear 2a7, and the driving gear 2a6 and the driven gear 2a7 are connected by a chain transmission. Both ends of the shoveling shaft 2a3 are fixedly connected with the front shell 7, and the The side wall is provided with several shoveling teeth 2a8 arranged at equal intervals, and the shoveling teeth 2a8 are arc-shaped, and each of the mounting plates 2a2 is provided with a cutting edge 2a11; by pushing the material on the mounting plate 2a2 Rake 2a9 is repla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com