Multicomponent alloy type anticorrosive material device

A technology of anti-corrosion materials and multi-element alloys, which is applied in mixers, transportation and packaging, mixers with rotating containers, etc., can solve the problems of inconvenient disassembly and cleaning of mixing sheets, low mixing efficiency, etc., and achieve low efficiency, The effect of high mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

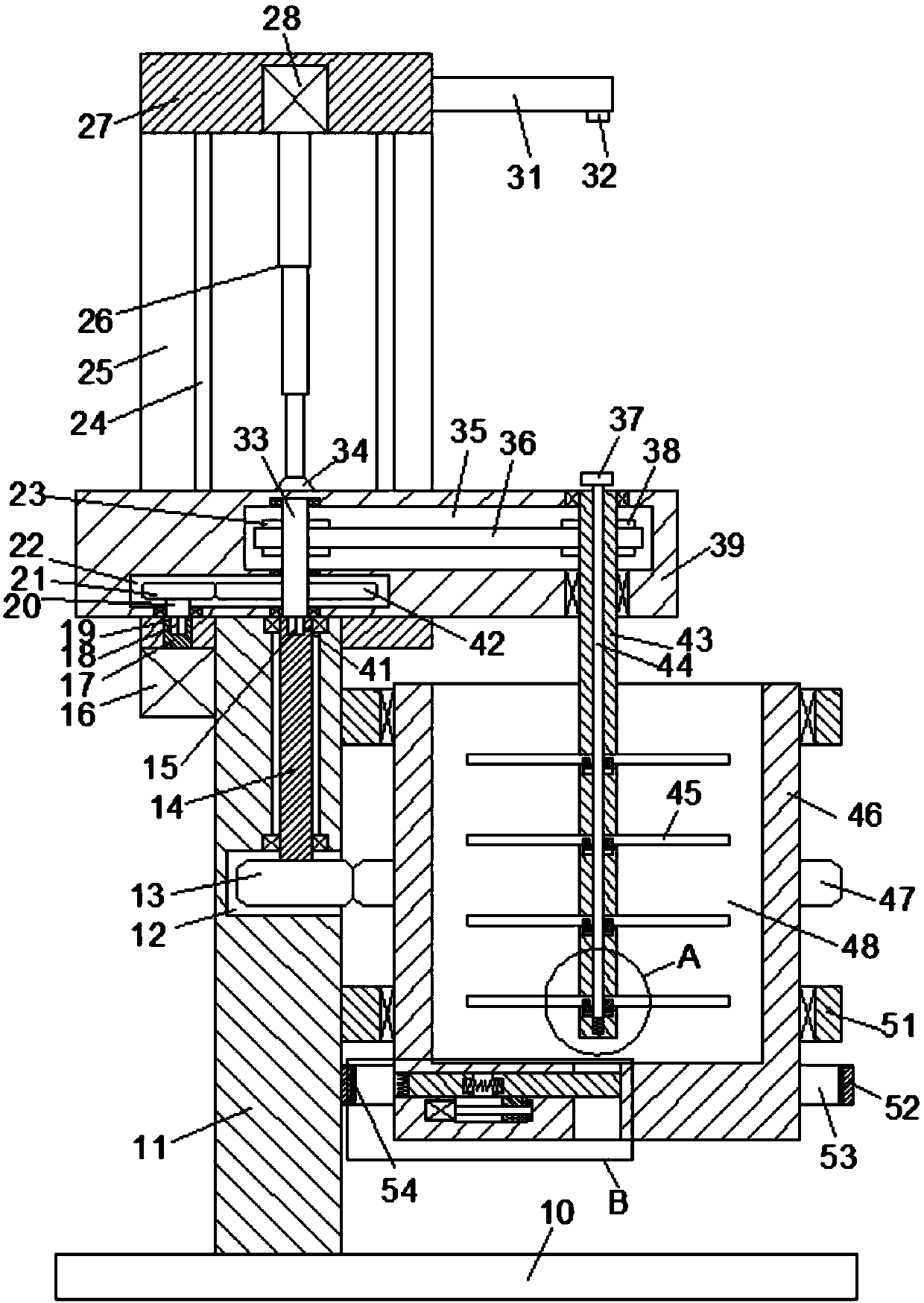

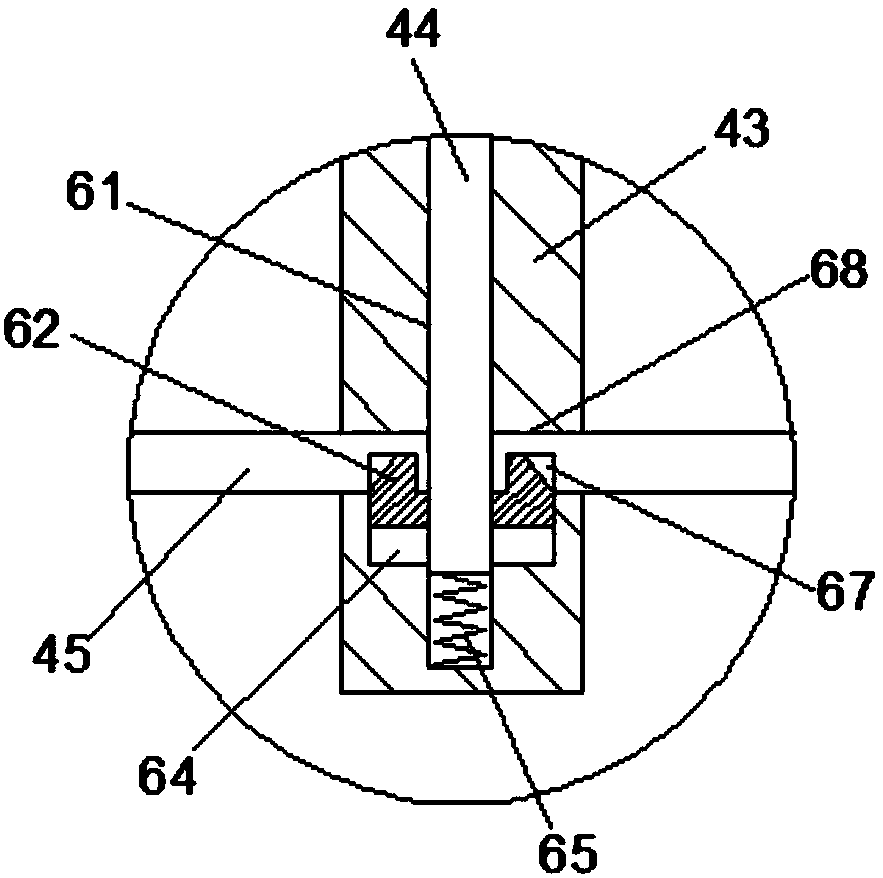

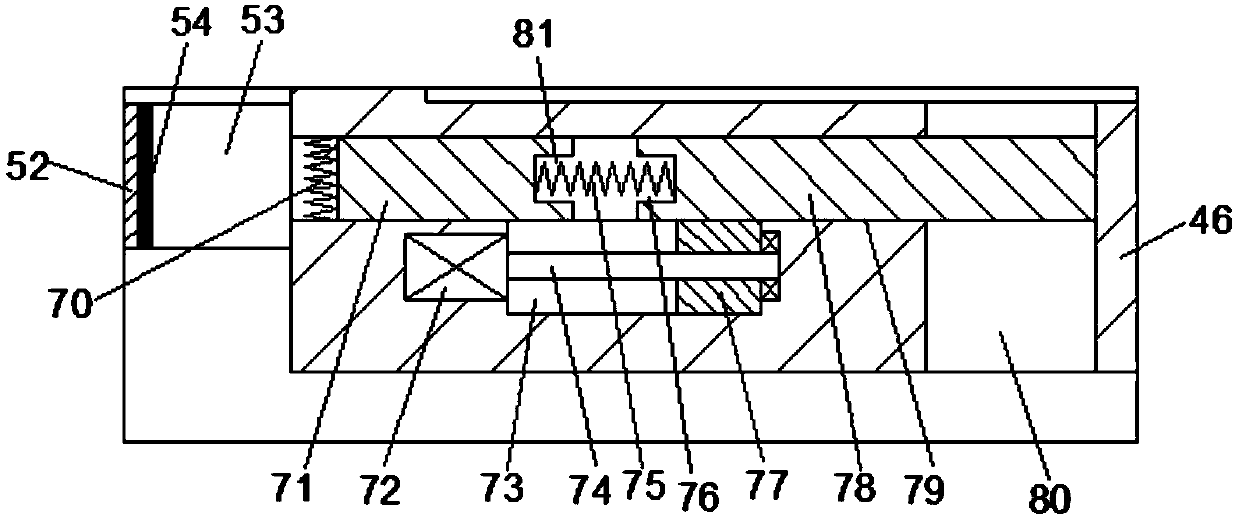

[0014] Combine below Figure 1-3 The present invention will be described in detail.

[0015] refer to Figure 1-3 , according to an embodiment of the present invention, a multi-component alloy type anti-corrosion material device includes a base plate 10, a support base frame 11 is installed on the base plate 10, a support top frame 27 is fixed on the support base frame 11, and the A mounting plate 51 is fixed symmetrically up and down on the right end surface of the support chassis 11. A storage tank 46 is arranged in the installation plate 51. A storage space 48 is provided in the storage tank 46. The right side of the support chassis 11 An embedding cavity 12 is provided in the side end surface, and a driving shaft 14 is installed in rotational cooperation between the top wall of the embedding cavity 12 and the top end surface of the support chassis 11, and a first gear 13 is fixed at the bottom end of the driving shaft 14, The outer periphery of the storage barrel 46 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com