Negative-pressure cleaning machine

A negative pressure cleaning and cabin technology, which can be used in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., and can solve problems such as single application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

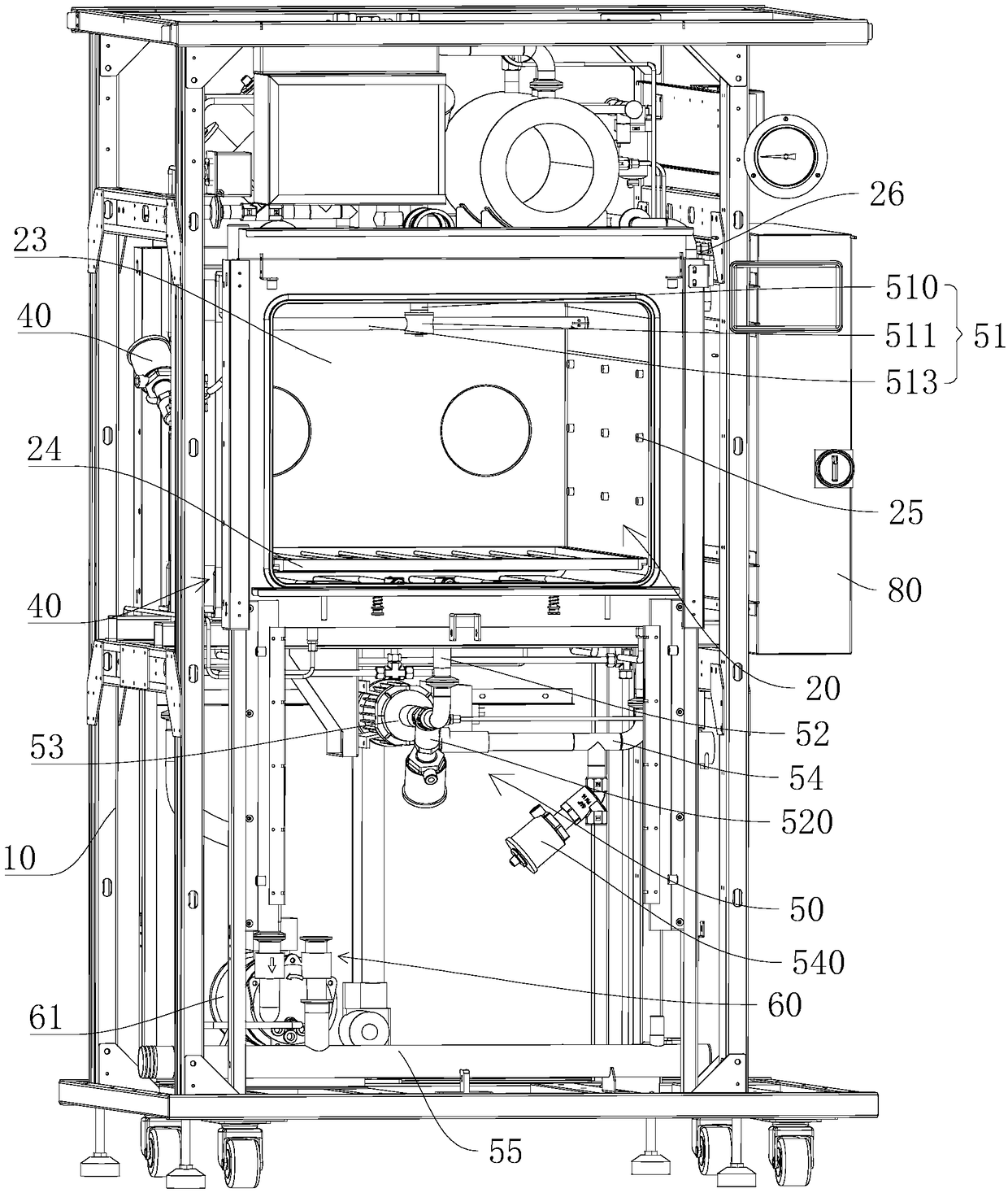

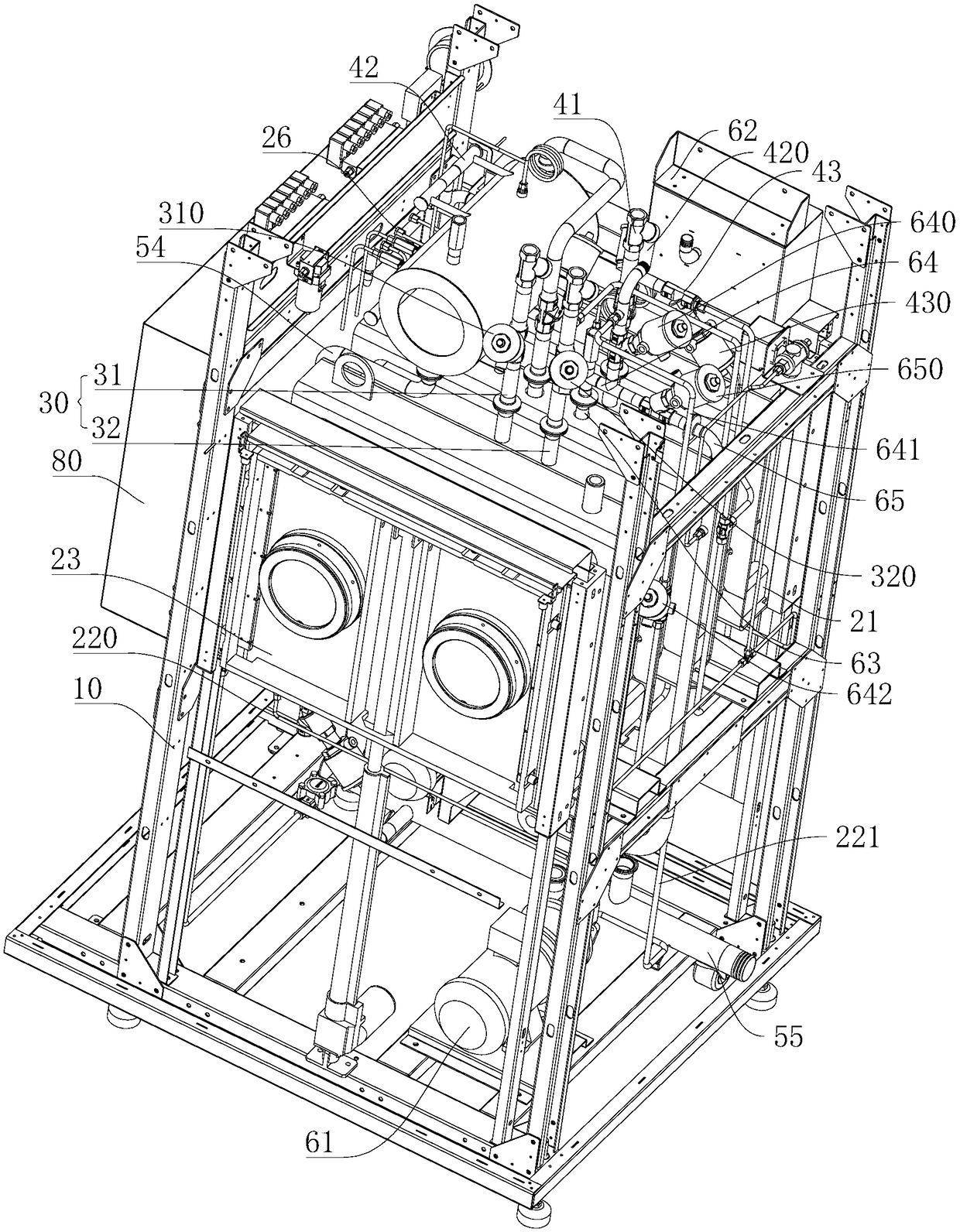

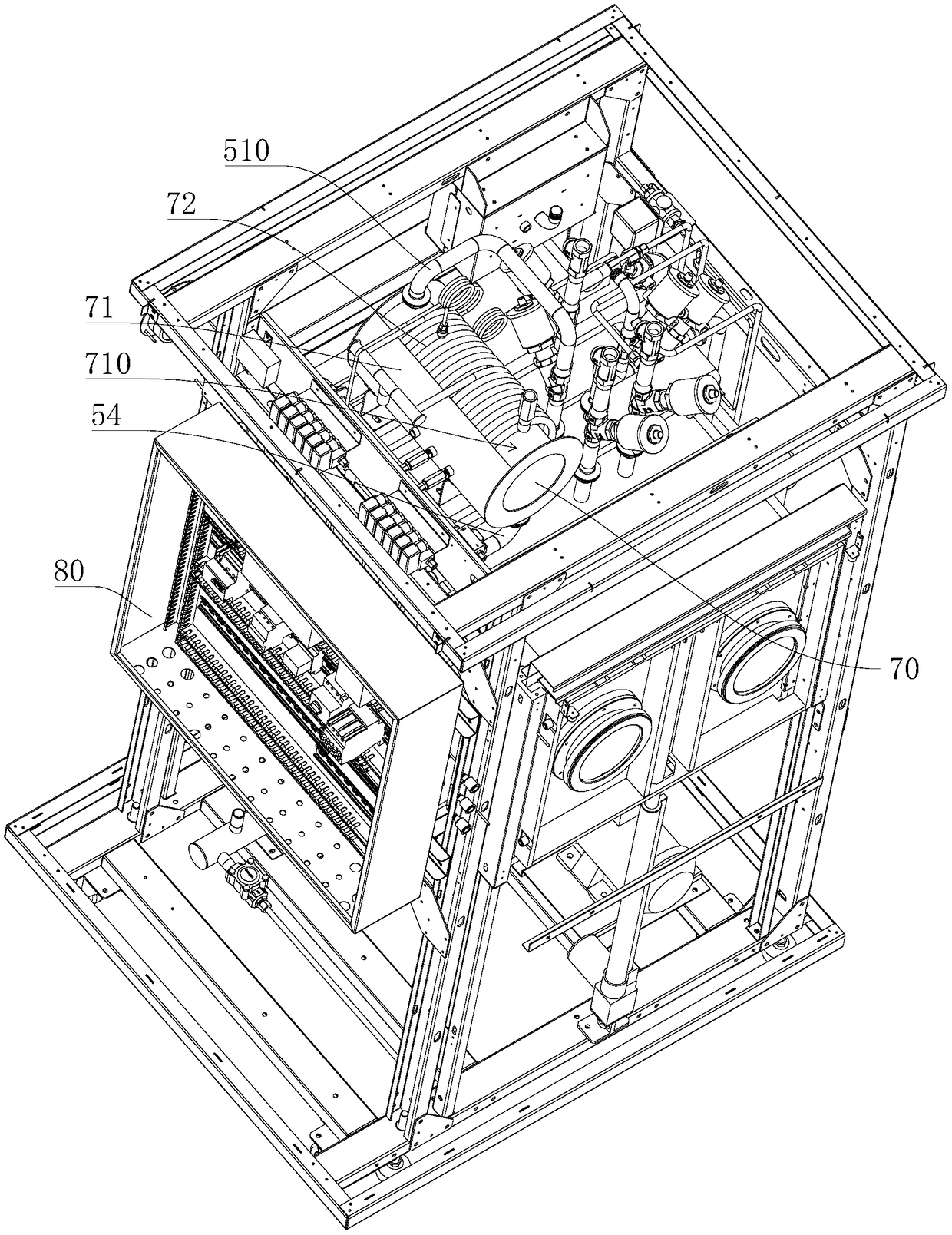

[0026] Please refer to figure 1 and figure 2 As shown, the embodiment of the present invention provides a negative pressure cleaning machine, including a rack 10 and a cleaning chamber 20, the rack 10 is used for installing and supporting the cleaning chamber 20, and the cleaning chamber 20 is used for cleaning and sterilizing various instruments .

[0027]The negative pressure cleaning machine also includes a control system 80 and a liquid supply mechanism, a steam heating system 40, a liquid circulation system 50, a vacuum mechanism 60 and a circulation heater 70 controlled by the control system 80. The control system 80 here is a PLC controller, It can also be other controllers, which can be programmed into the control software to control the automatic operation of the equipment. The liquid supply mechanism is used for supplying liquid for cleaning equipment into the cleaning chamber 20; the steam heating system 40 is used for heating the side wall of the cleaning chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com