A low-pressure turbine installation device and its use method

A low-pressure turbine and equipment installation technology, which is applied in metal processing equipment, assembly machines, workpiece clamping devices, etc., can solve problems such as not being conducive to ensuring the accuracy of casing hole positions, relying on worker experience, and increasing equipment costs, so as to achieve convenience and independence Effect of rotation control, reduction of rotation and lost motion, and reduction of equipment load

Active Publication Date: 2019-10-01

AECC COMML AIRCRAFT ENGINE CO LTD +1

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

All bolt holes correspond to M6 bolts and the hole diameter is only 6.5mm, and the diameter of the distribution circle is about 1.1m, so if the rotation error of the stator exceeds arctan(0.5 / 1100)≈0.026°, the hole positions will not be aligned

2. High limit requirements for the axial movement of the low-pressure turbine rotor and stator

1) The rotation control of the rotor and the stator as a whole is not conducive to ensuring the accuracy of the alignment of the casing holes

Since the splines are half engaged before the casing holes are aligned, when the low-pressure turbine stator casing is rotated for hole alignment, the fan rotor components (such as the fan shaft, etc.) The rotation of the low-pressure turbine shaft affects the rotation of the stator casing, which is not conducive to ensuring the alignment accuracy of the casing holes

2) The rotation control of the rotor and the stator as a whole reduces the alignment efficiency

The initial angular relative position of the low-pressure turbine shaft spline and the stator casing hole is not unique. If the rotor and the stator are rotated as a whole, unnecessary rotation will easily increase, resulting in increased cumulative errors and reduced alignment efficiency.

3) The rotation control of the rotor and the stator as a whole increases the equipment load, potential safety hazards and costs

For the rotation control equipment, when the rotor and the stator are connected as a whole, the control object is not a single low-pressure turbine rotor or stator, but a low-pressure turbine + fan rotor (including fan shaft and other rotor components), which leads to equipment control The moment of inertia of the object is greatly increased, which further leads to a significant increase in control difficulty and safety hazards, and increases equipment costs

2. During the assembly process, the rotation and attitude adjustment of the rotor and stator is mainly controlled by manpower, which is difficult to guarantee the accuracy of angle control, and it is easy to cause parts to bump, and it is heavily dependent on the experience of workers, with poor repeatability and low assembly efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

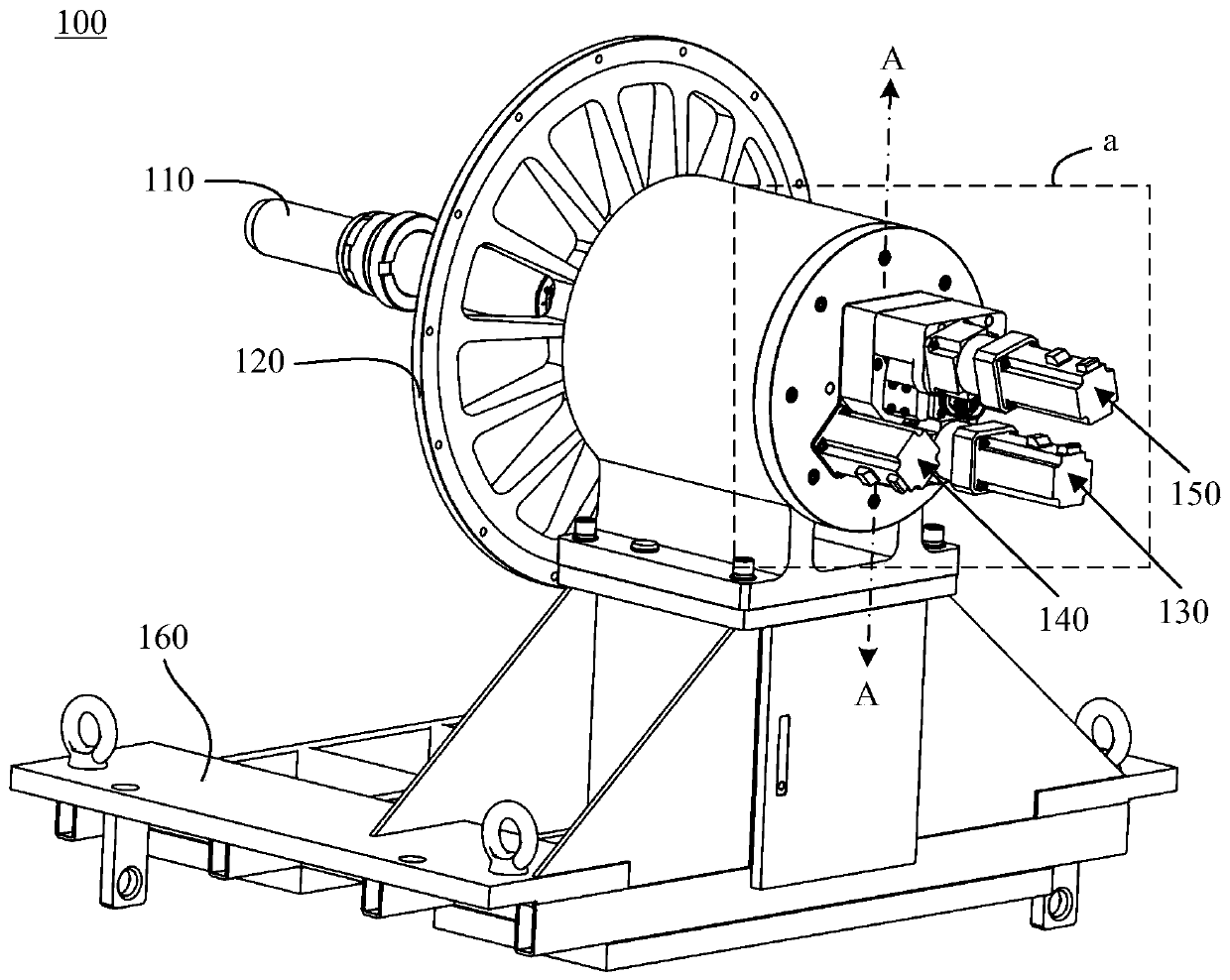

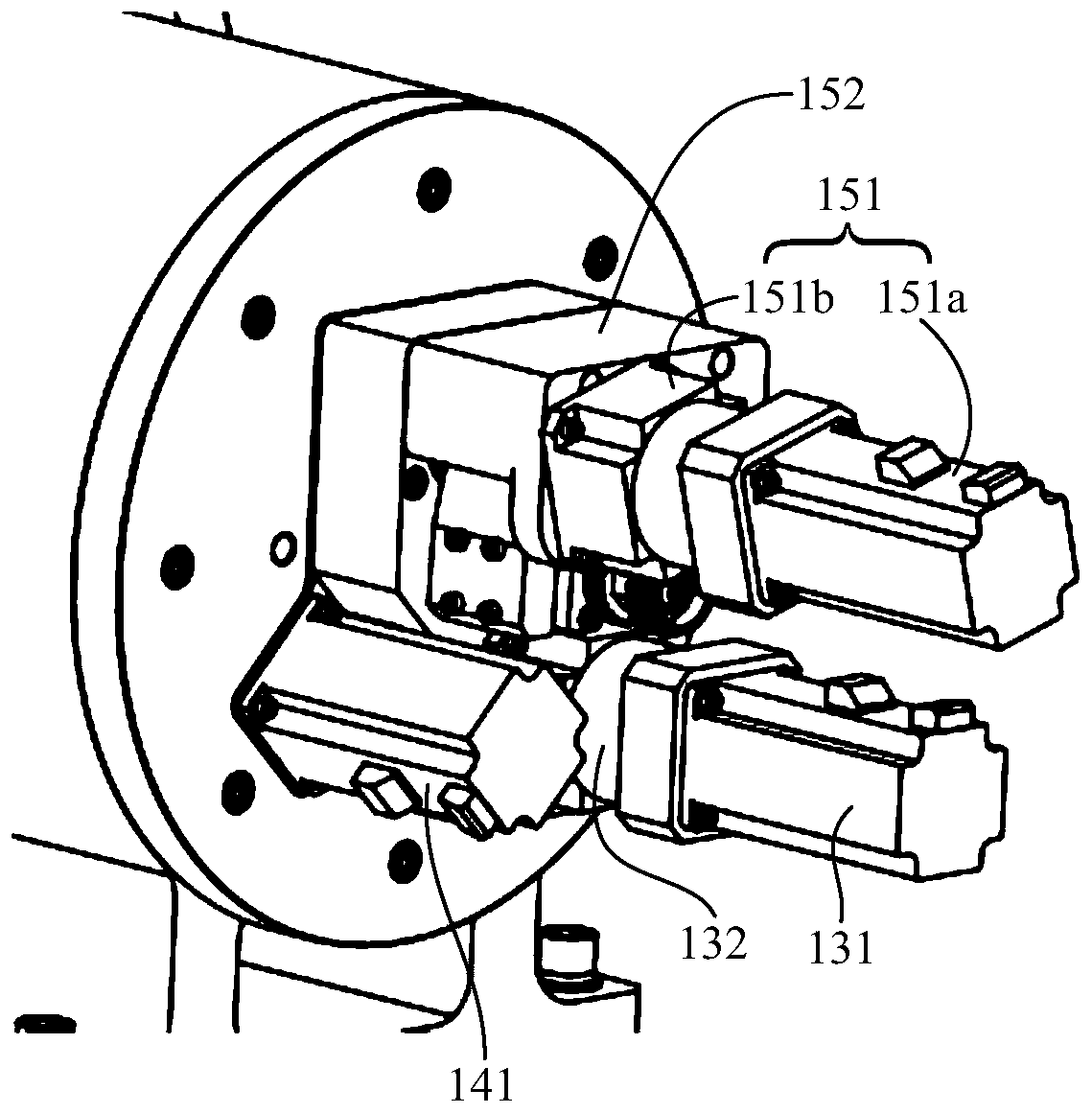

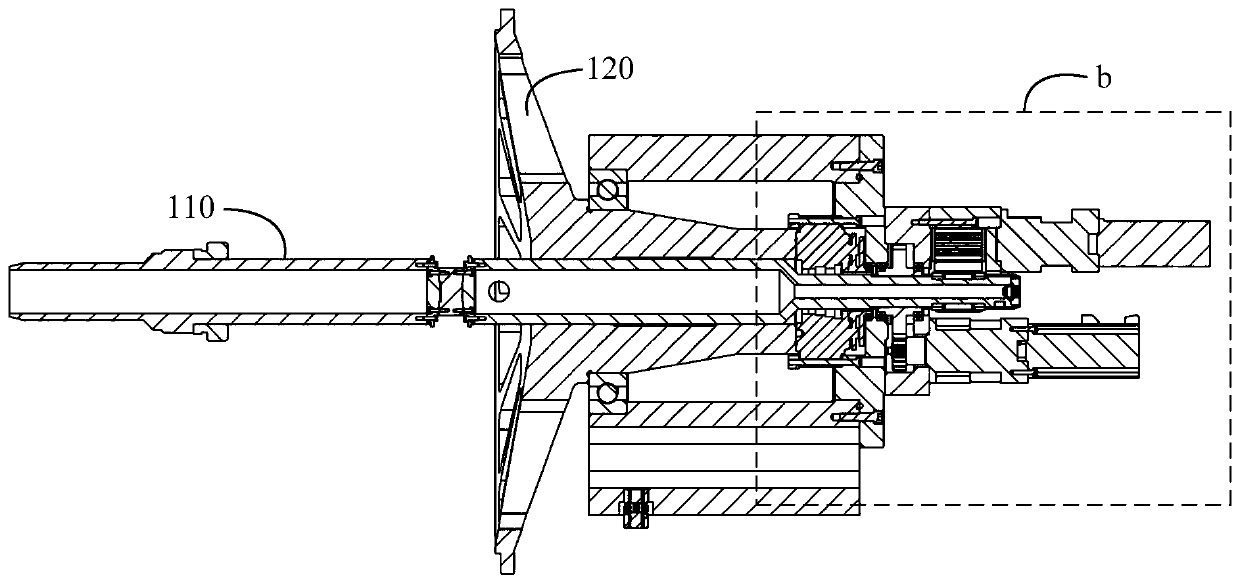

The invention provides a low-pressure turbine installation device and a method for installing a low-pressure turbine by using the low-pressure turbine installation device. The low-pressure turbine installation device comprises an inner rotating shaft, an outer rotating shaft, an inner rotating shaft rotation control assembly, an outer rotating shaft rotation control assembly and a holding mechanism; the inner rotating shaft is used for being connected with a rotor of the low-pressure turbine, the outer rotating shaft is used for being connected with a stator of the low-pressure turbine, wherein the inner rotating shaft and the outer rotating shaft are coaxial, and the inner rotating shaft and the outer rotating shaft can rotate mutually independently; the inner rotating shaft rotation control assembly is used for driving the inner rotating shaft to rotate, the outer rotating shaft rotation control assembly is used for driving the outer rotating shaft to rotate, and the holding mechanism is used for limiting the rotation and axial movement of the inner rotating shaft relative to the outer rotating shaft. The low-pressure turbine installation device can independently control the rotor and the stator of the low-pressure turbine to rotate in the assembling process, and has the characteristics of being high in control precision, high in assembly efficiency, high in safety, low in cost and the like.

Description

technical field The invention mainly relates to the field of aero-engine assembly, in particular to a low-pressure turbine installation device and a use method thereof. Background technique The final assembly of aero-engine is an important part of aero-engine assembly, and the assembly effect directly affects the quality of the engine product. During the assembly process, the fan core machine and the low-pressure turbine need to be docked. It is required to insert the low-pressure turbine shaft (rotor) of the low-pressure turbine with a length of about 2m into the fan core machine. The alignment of the holes in the casing, the bolt connection, and the tightening of the large nut of the low-pressure turbine shaft must ensure three joints in this process: (1) the spline engagement between the low-pressure turbine shaft and the fan shaft (belonging to the fan core machine); 2) Bolt connection between the front end of the low-pressure turbine stator casing and the rear end of t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23P21/00B25B11/02

Inventor 张潇陈栋权项宏伟

Owner AECC COMML AIRCRAFT ENGINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com