Circular gantry robot moving system

A mobile system and robot technology, applied in the field of robotics, can solve problems such as large-span mobile operations, size changes, and robot arm spans not meeting applicable requirements, to achieve the effect of ensuring accuracy and avoiding size changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

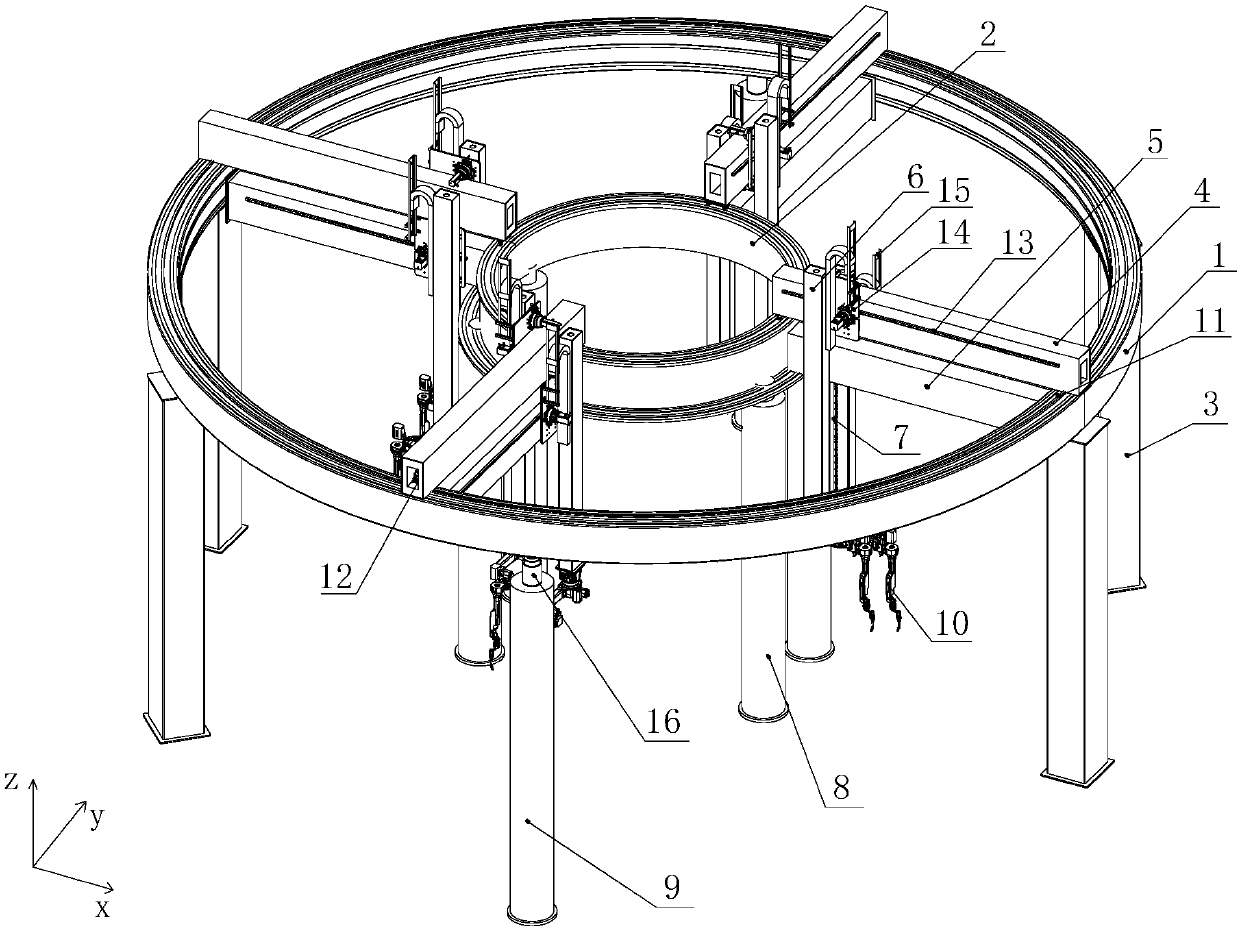

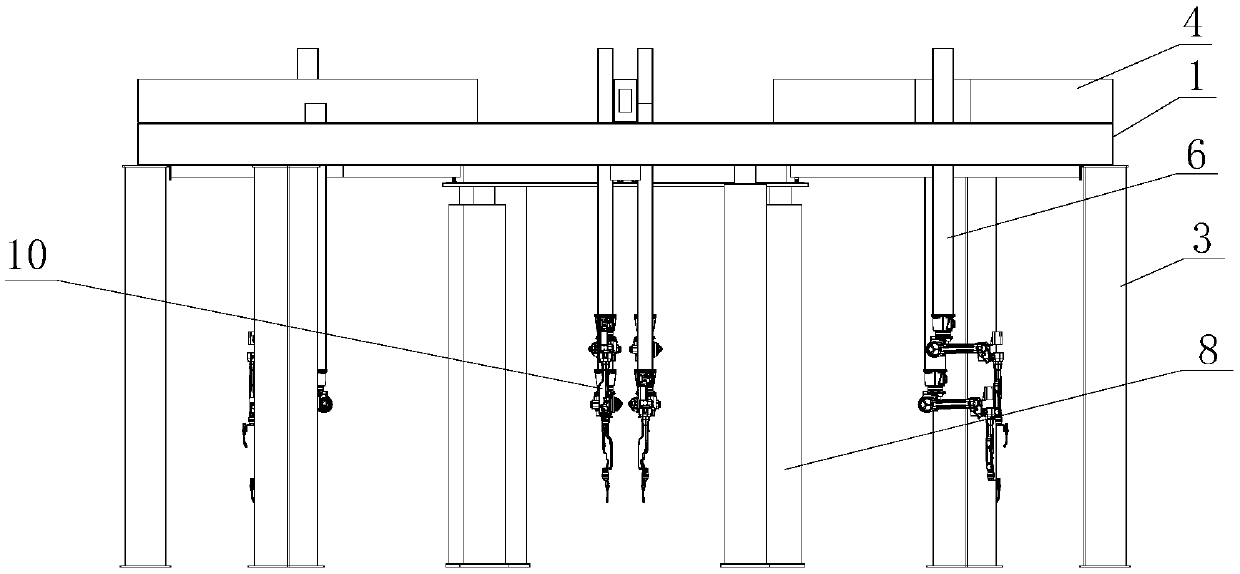

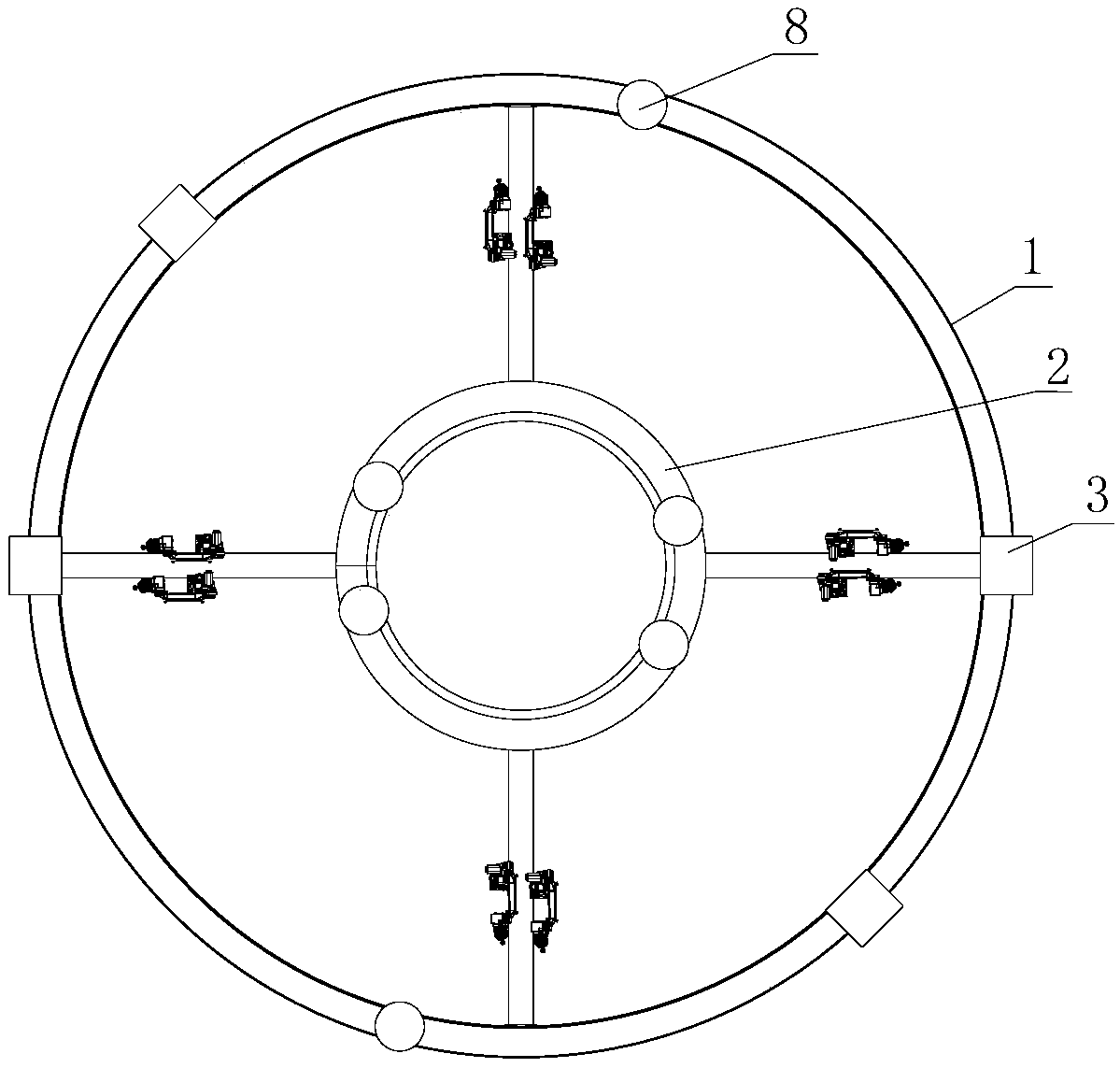

[0021] Due to the dimensional changes caused by the temperature difference in the working environment of the existing gantry-type equipment in the welding and cutting of circular workpieces, it is difficult to ensure the accuracy of each axis in different situations. At the same time, the working stroke of the robot or other end-effectors The request cannot be met.

[0022] Aiming at the problems existing in the prior art, the present invention adopts an XYZ three-axis traveling mechanism, wherein the X-axis is designed in a ring shape, which avoids the size change caused by the temperature difference in the working environment, and the Y-axis and Z-axis change synchronously with the workpiece, thus ensuring that each The precision of the axes in different situations.

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com