Corrugated roller of corrugated structure with functions of decreasing paper gram weight and not lowering paperboard strength

A corrugated roll and corrugated roll type technology, which is applied in the field of corrugated rolls for corrugated cardboard processing to achieve the effects of increasing corrugated rolls, wide forming area, and improving stress and impact conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

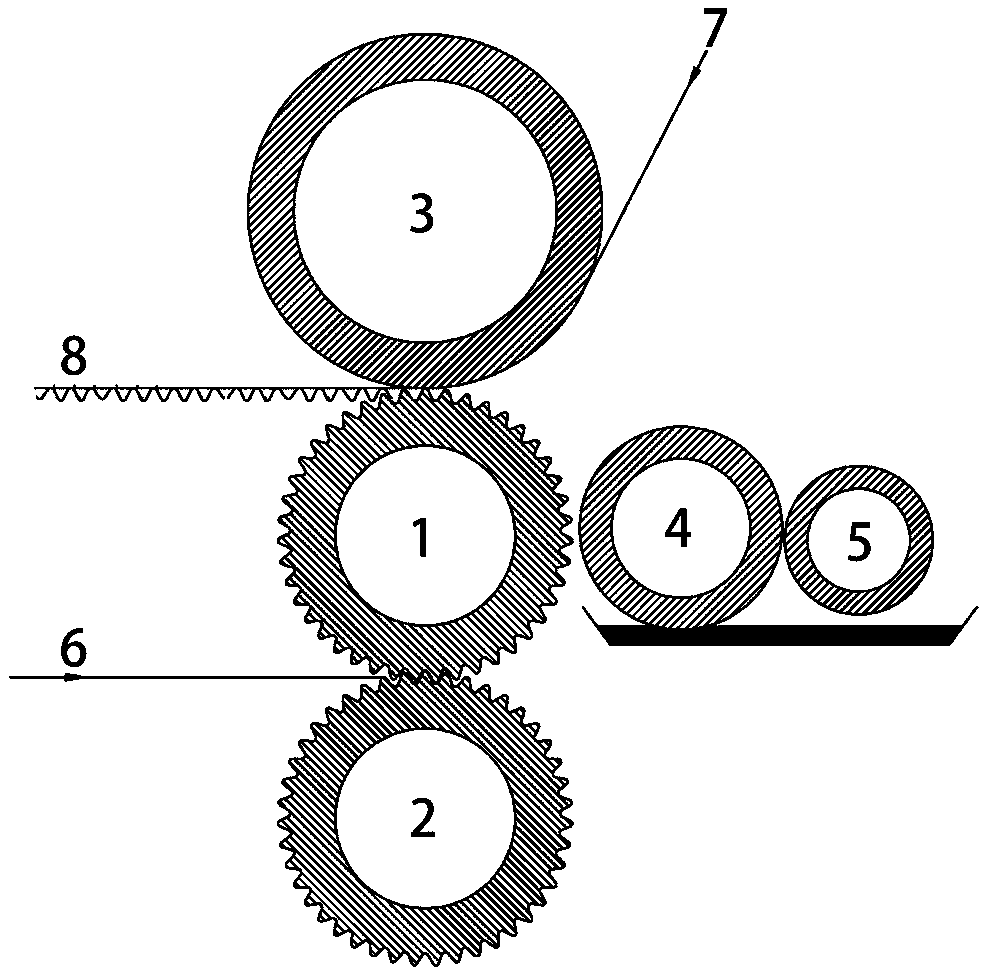

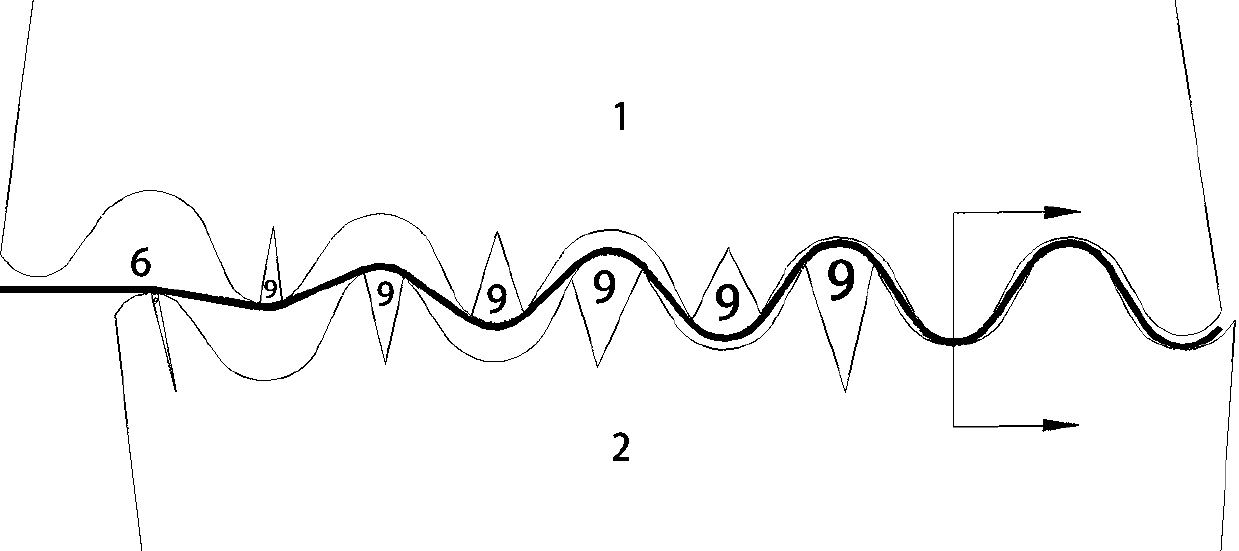

[0042] In order to make the technical means, technical features, objectives and effects achieved by the present invention easy to understand, further elaborations will be made below in conjunction with specific drawings and preferred implementation process steps.

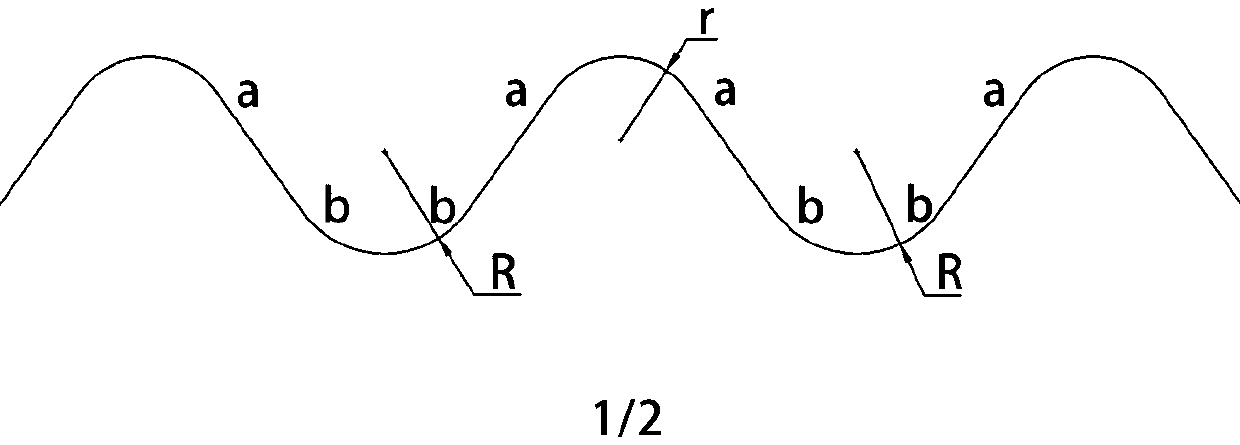

[0043] As can be seen from Fig. 5, the corrugated top arc of the corrugated roll of the present invention comprises: the radius r is the corrugated top arc ac and the radius is the second corrugated top arc cc of r2, and the size of the second corrugated top arc r2 is between Between the top arc r and the bottom arc R, the second top arc r2 is located at the top or middle of the top arc aa, and the second top arc r2 is tangent to the top arc r, The second corrugated top arc r2 can be one section of arc, or three sections or more than three sections of arcs including transition optimization function.

[0044] Step 1: Design of flute type parameters: According to the flute type characteristics of the corrugated roll w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com