Multistage scouring toilet bowl without water tanks and method for flushing multistage scouring toilet bowl

A water tankless, multi-stage technology, applied to flushing equipment with water tanks, flushing toilets, water supply devices, etc., can solve the problems of increased wiring costs, potential safety hazards, and inability to flush thoroughly, and achieve good flushing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution in the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them.

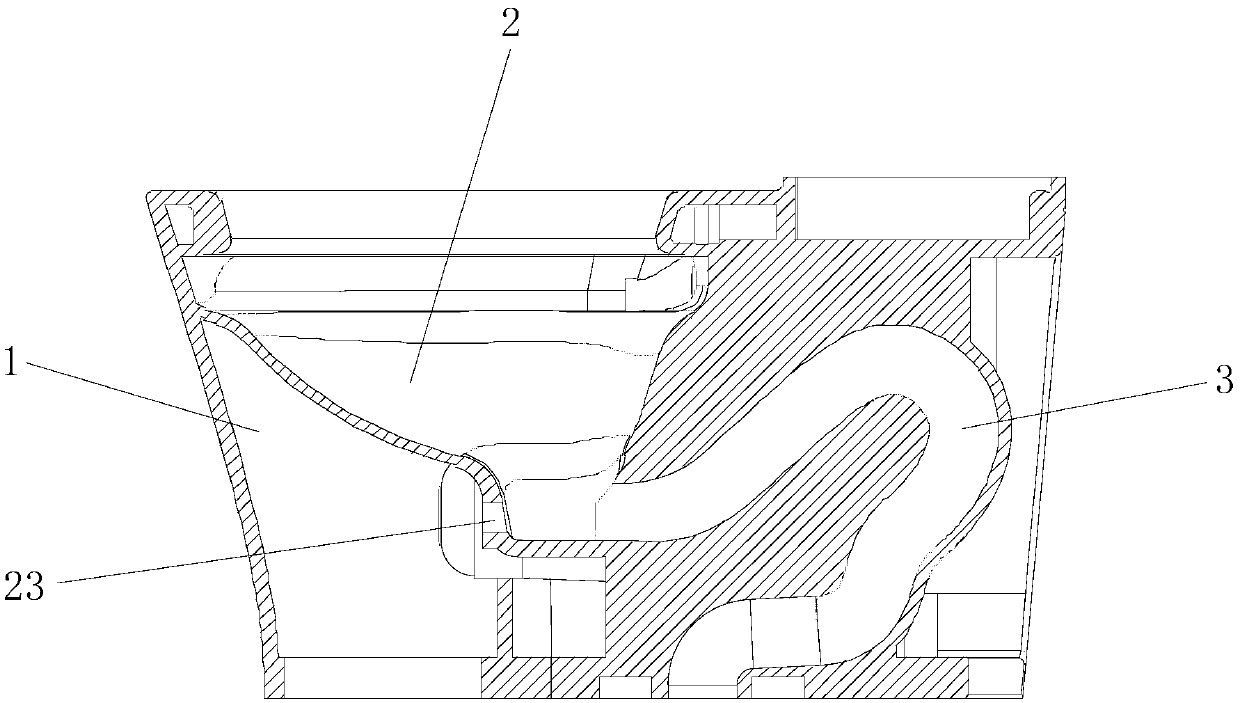

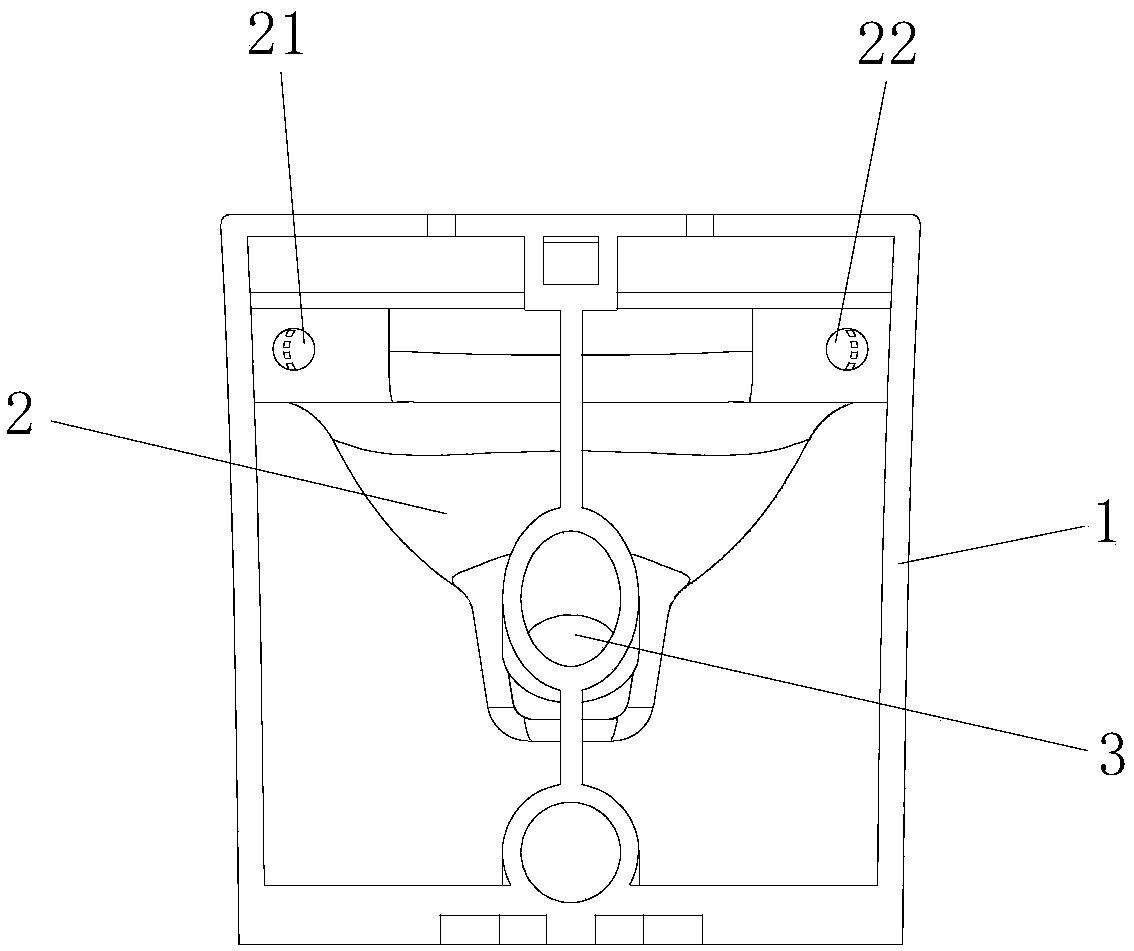

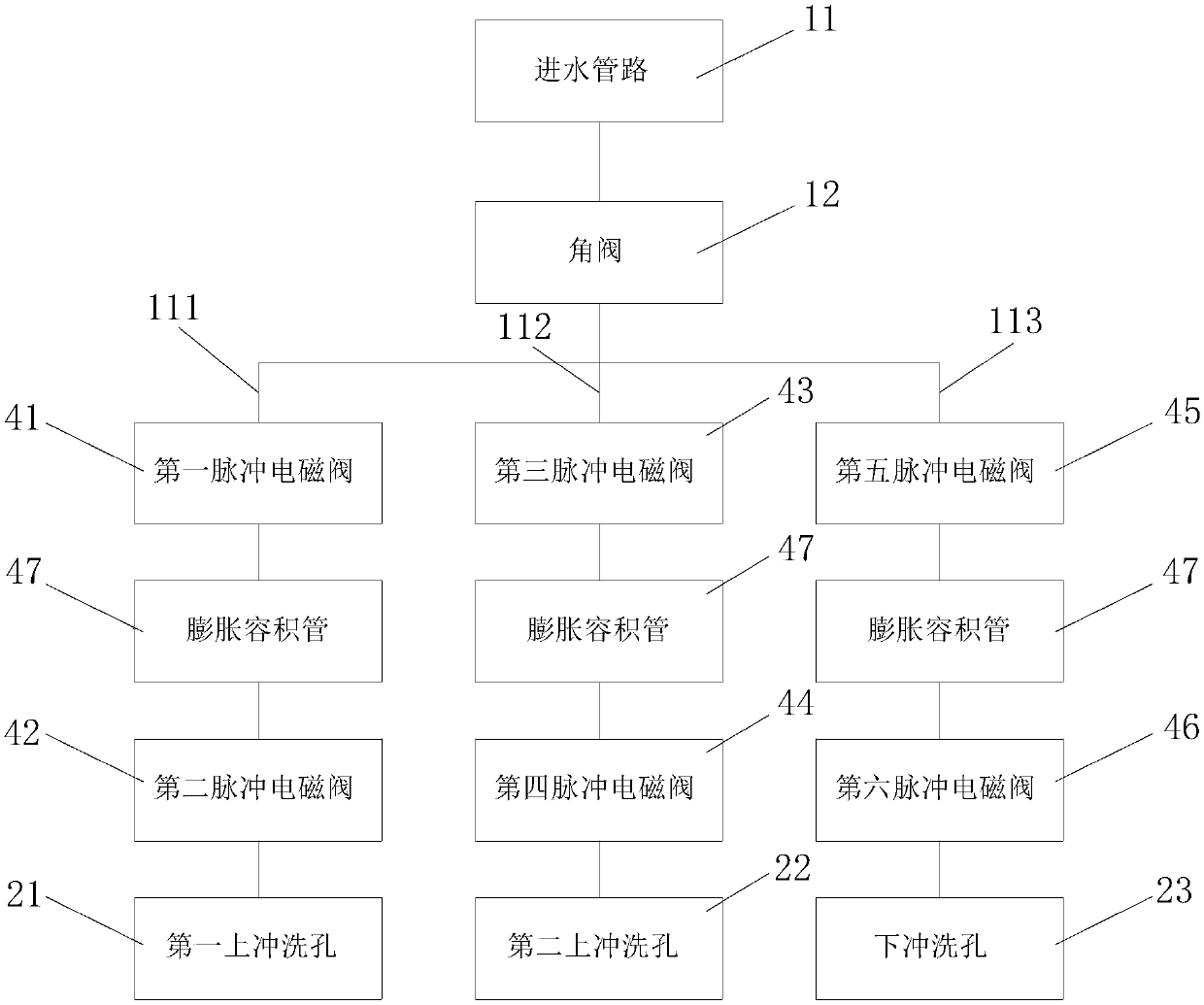

[0029] refer to Figure 1 to Figure 5 As shown, the present invention discloses a tankless toilet with multi-stage flushing, comprising a barrel body 1, a pelvic cavity 2, a sewage pipe 3, and a pulse flushing device 4. The barrel body 1 is connected with a water inlet pipeline 11, and the The water inlet pipeline 11 is provided with an angle valve 12, the pelvic cavity 2 is set in the bucket body 1, the sewage discharge pipe 3 is set at the bottom of the pelvic cavity 2, and the pelvic cavity 2 is provided with a first upper flushing hole 21 2. The second upper flushing hole 22 and the lower flushing hole 23. The first upper flushing hole 21 and the second upper flushing hole 22 are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com