Counter pressure type valve body assembly

A technology of valve body and components, which is applied in the field of counter-pressure valve body components, which can solve problems such as too simple ventilation and closing forms, insufficient tightness of valve hole compression fit, and weak airtightness, etc., to achieve simple structure and increase sealing performance , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

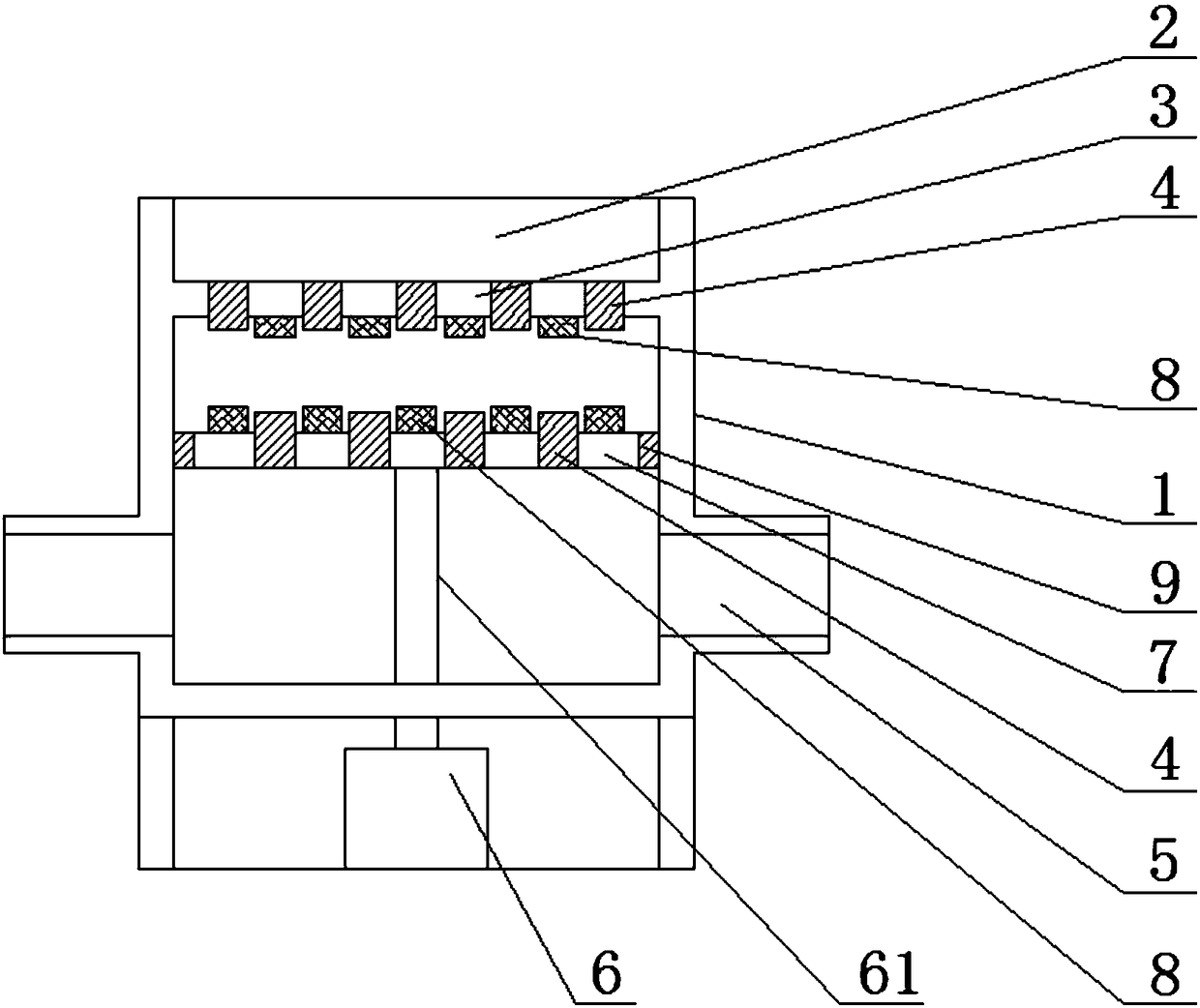

[0015] like figure 1 As shown, a counter-pressure valve body assembly includes a valve housing 1; the upper end of the valve housing 1 is set as an inlet end 2, and a sealing plate 3 is installed at the inlet end 2 of the valve housing 1, and the The above-mentioned sealing plate 3 is provided with a valve hole 4; and the middle and lower part of the valve casing 1 is also provided with a laterally placed outlet pipe 5, and the described outlet pipe 5 communicates with the valve cavity in the valve casing 1; the valve The lower end of the casing 1 is also equipped with a driving cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com