Plastic double-rib winding corrugated pipe

A corrugated pipe and plastic technology, which is applied in the field of plastic winding corrugated pipes, can solve the problems of insufficient tensile strength of the lap joint, inability to release heat, and inability to realize benefits, etc., to reduce the weight of the meter, not easy to collapse, improve the ring stiffness and The effect of stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, the plastic double-ribbon wound corrugated pipe of the present invention will be further described in detail through specific embodiments.

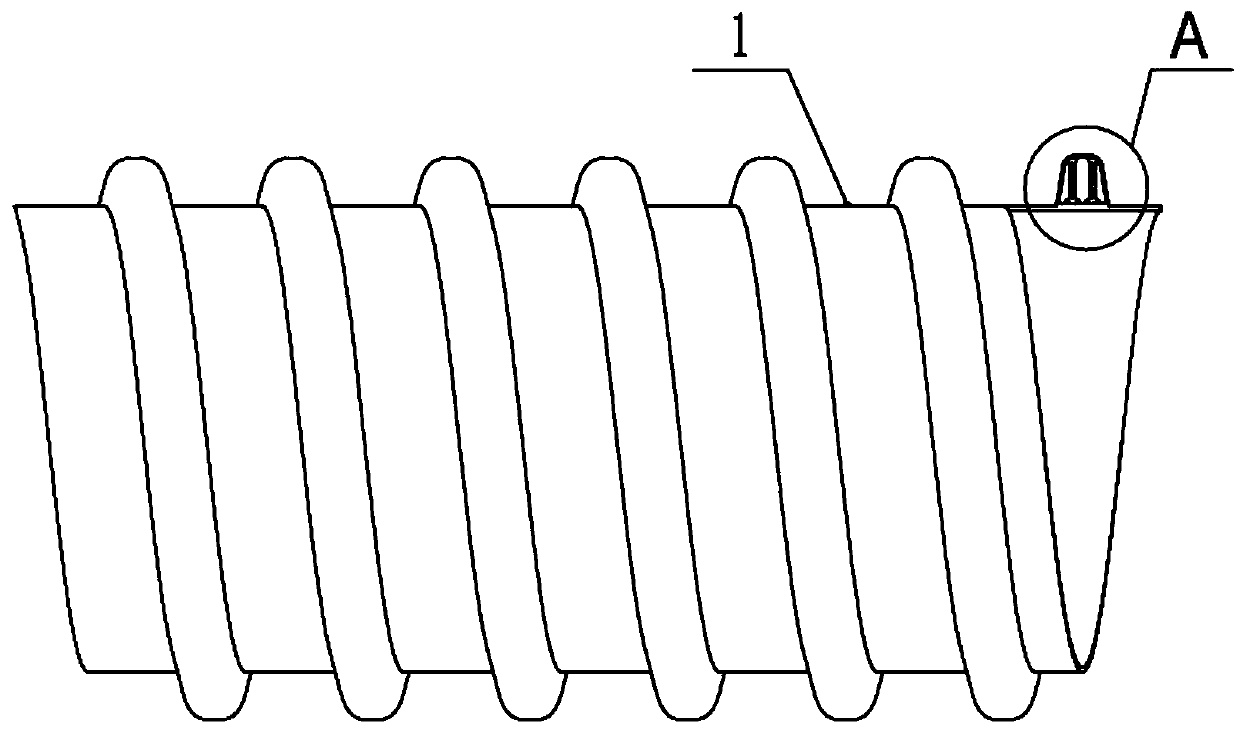

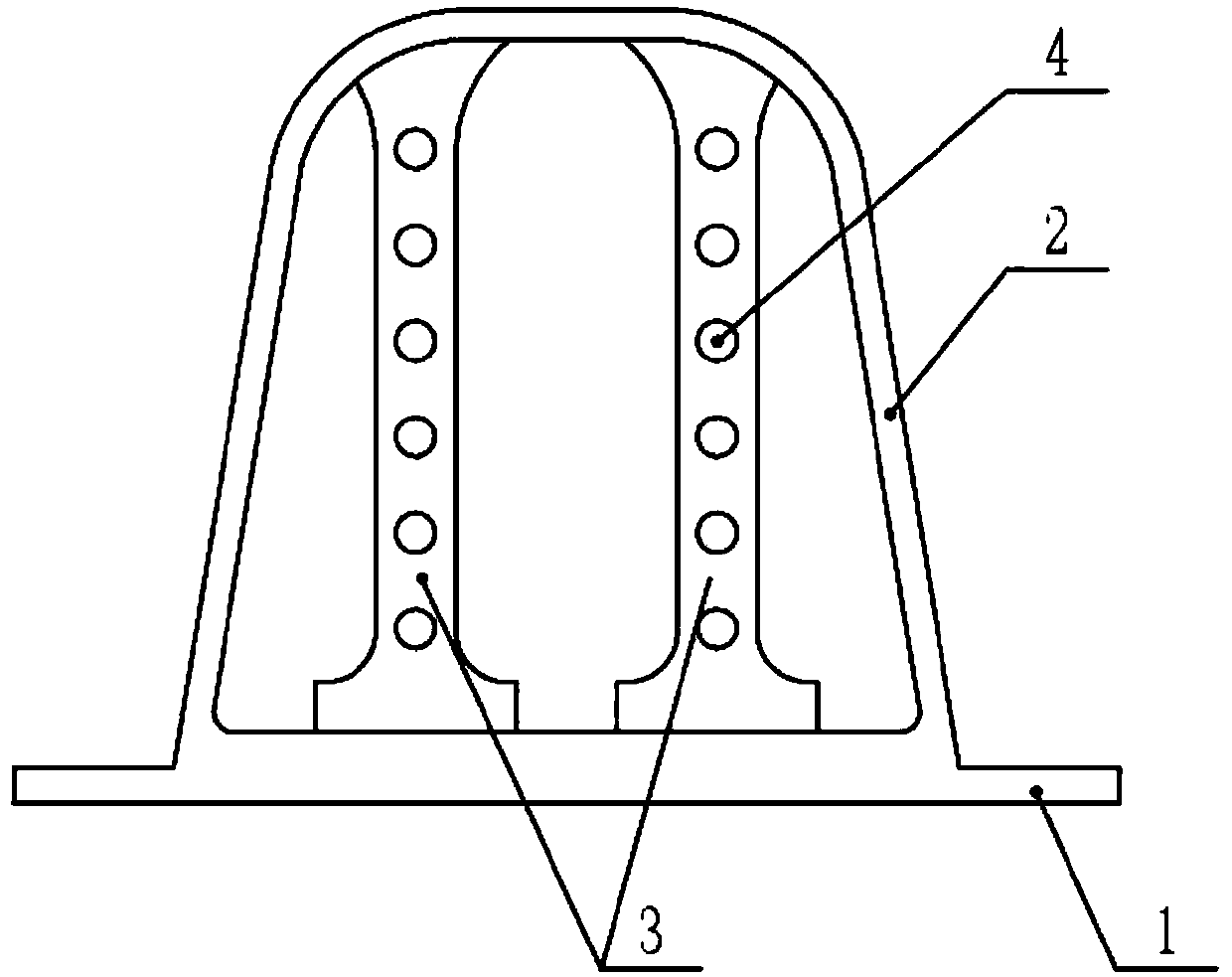

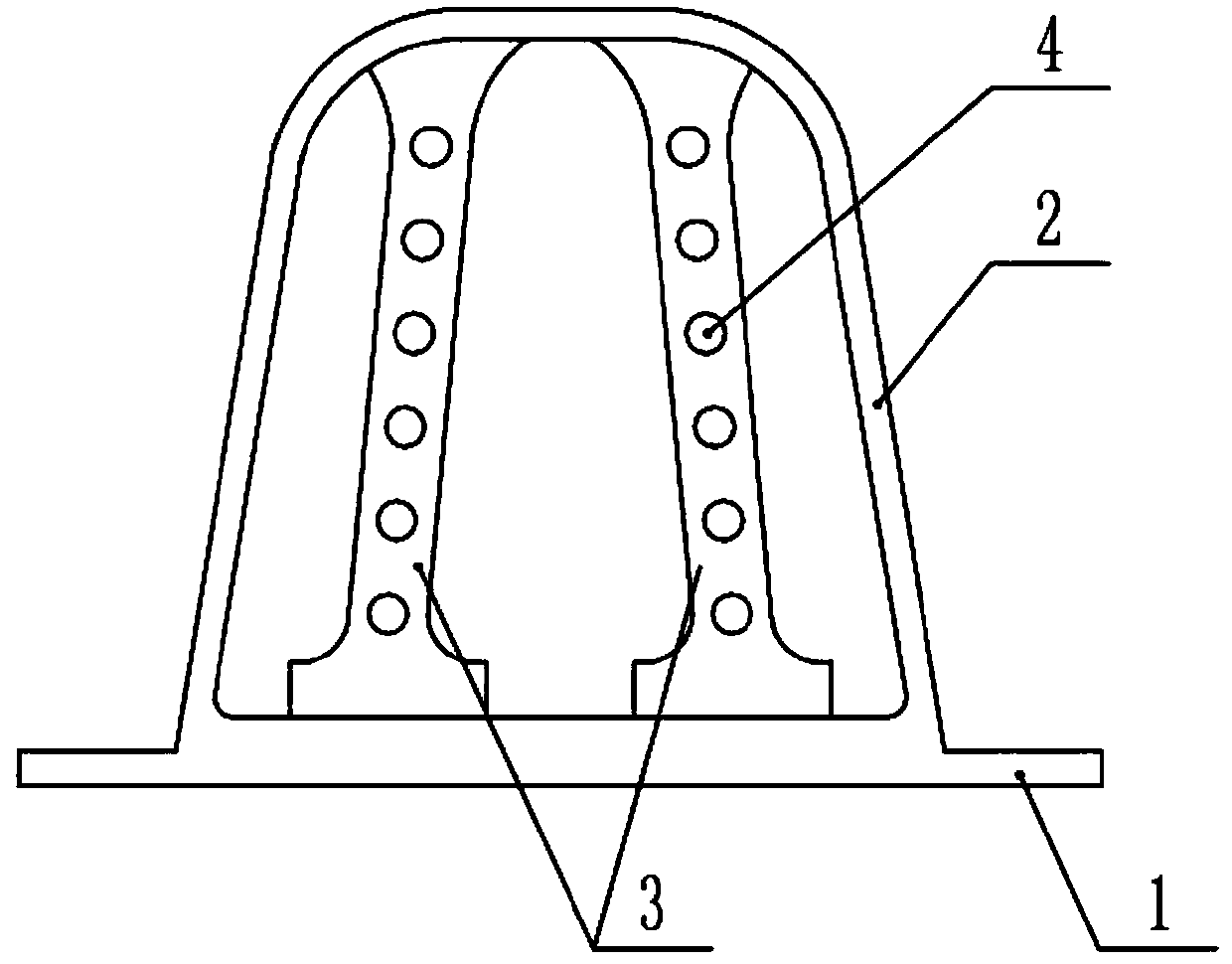

[0023] Such as figure 1 , figure 2 As shown, a plastic double-ribbed corrugated pipe includes a pipe bottom tape 1 and a plastic profile. The plastic profile is spirally wound on the outside of the pipe bottom tape 1 to form an outer corrugated shape. The plastic profile includes a hollow body 2 and a vertical rib. 3. There are at least two vertical ribs 3, and the vertical ribs 3 and part of the main body 2 form a trilateral or quadrilateral support structure. The vertical rib 3 is provided with a longitudinal through hole 4.

[0024] Three examples of the present invention are given below, and the number of the standing ribs 3 is two, but the number of the standing ribs 3 can also be multiple, which all belong to the protection category of the present invention.

[0025] Such as figure 2 Shown is an embodiment of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com