Chromatographic automatic sampler and automatic sampling method

An automatic sampling and chromatographic technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of the influence of measurement results, poor repeatability of non-destructive sampling, etc.

Active Publication Date: 2018-12-28

ANHUI WAYEE SCI & TECH CO LTD

View PDF13 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the repeatability of non-destructive sampling is poorer among the three sampling methods, and a large amount of filling liquid injected into the pipeline will also have a certain impact on the measurement results

Therefore, the current above-mentioned several automatic sampling methods all have certain defects, and need to be improved urgently.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

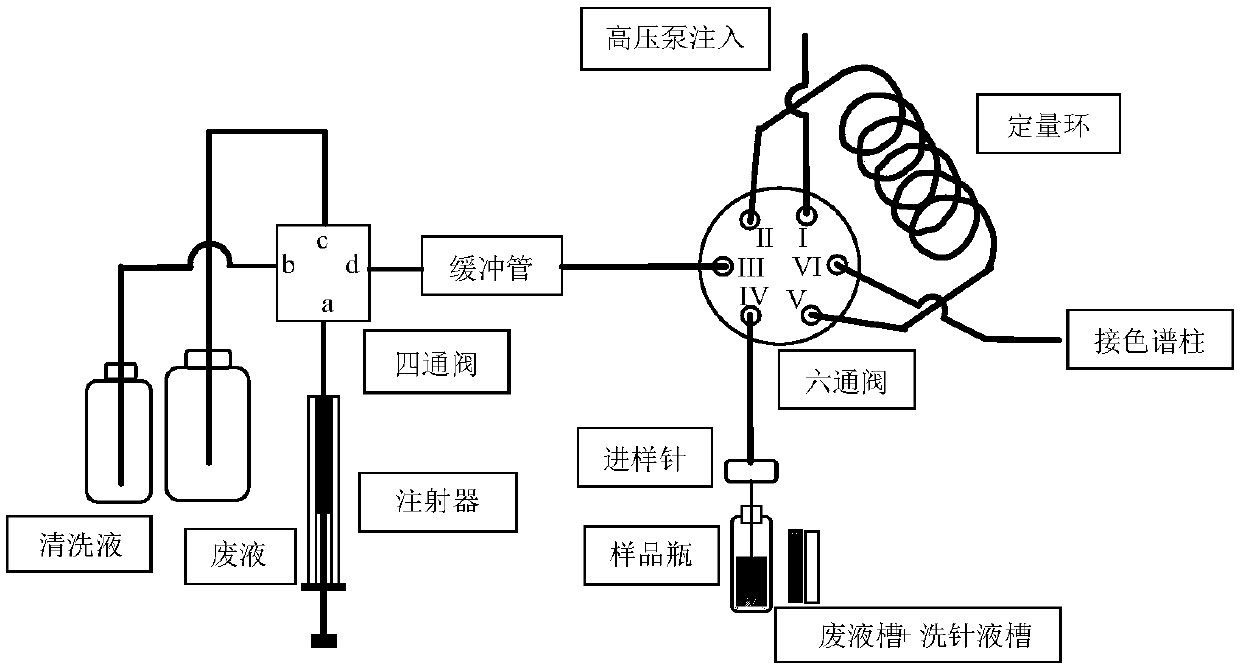

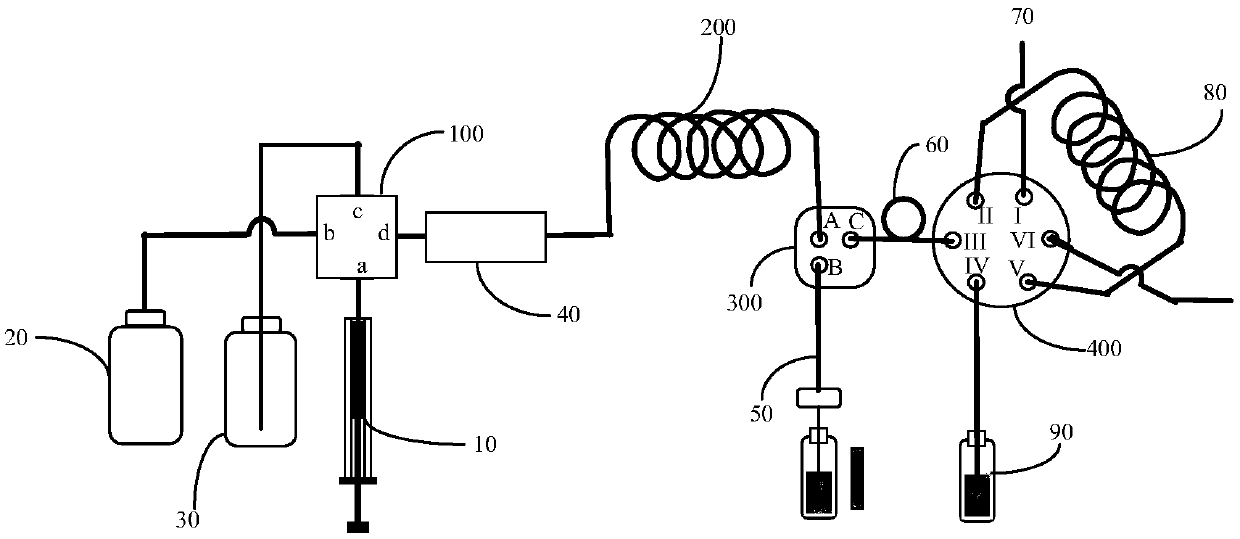

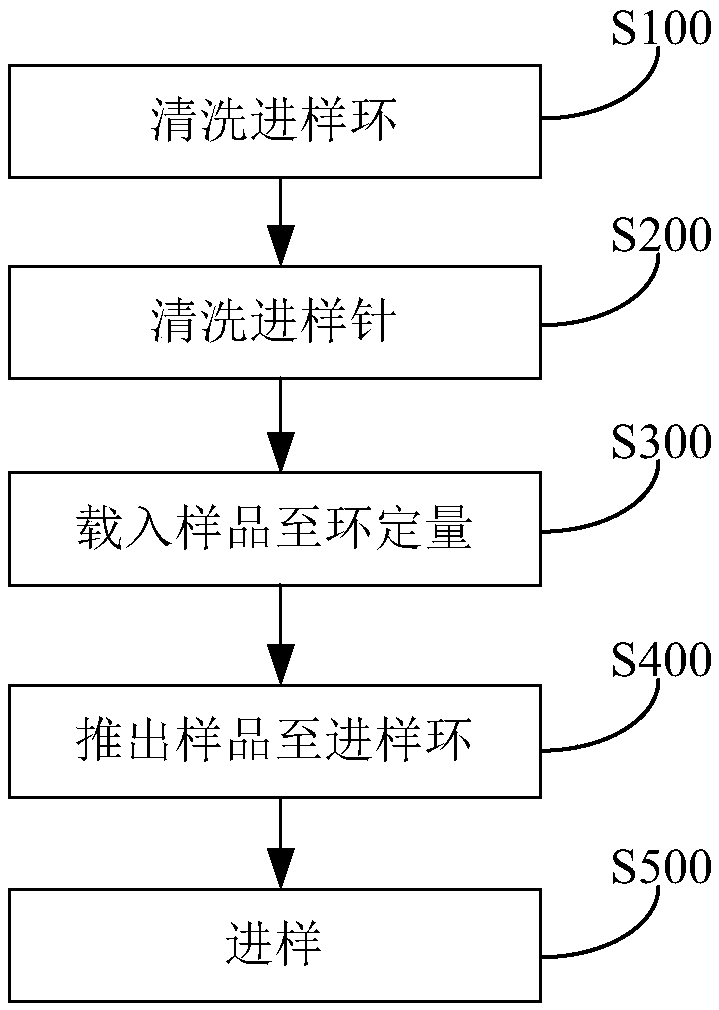

The invention discloses a chromatographic automatic sampler and automatic sampling method. The chromatographic automatic sampler comprises a four-way valve, a quantitative loop, an injection valve anda six-way valve, wherein the four-way comprises four ports a, b, c and d and outer ends of the four ports are respectively connected with an injector, a cleaning fluid storage bottle, a first waste fluid bottle and a buffer tube; one end of the quantitative loop is communicated with the buffer tube; the injection valve comprises three ports A, B and C and two passages respectively used for communicating the ports A and C and communicating the ports A and B in a switchable manner; the outer ends of the three ports A, B and C are respectively connected with the other end of the quantitative loop and one ends of a sampling needle and a connection ring; the six-way valve comprises six ports I, II, III, IV, V and VI and the outer ends of the six ports are respectively connected with one ends of high-pressure leacheate and a sampling ring, the other end of the connection ring, the other ends of another waste fluid bottle and the sample ring and a chromatographic column. When being used forcarrying out automatic sampling, the chromatographic automatic sampler has the advantages of being high in sampling amount correctness and high repeatability.

Description

technical field The invention belongs to the field of chemical analysis instruments, and in particular relates to a novel chromatographic automatic sample injector and an automatic sample injection method. Background technique In the analysis process using liquid chromatography or ion chromatography, in order to automatically introduce multiple samples into the flow path and into the column in a predetermined order, an autosampler is usually used. Compared with manual injection, automatic sampler has the advantages of high efficiency, high repeatability, small dead volume, pollution prevention, and labor saving. The combination of six-way switching valve and quantitative sample loop for sampling is currently the most ideal sampling method with high repeatability. Major manufacturers generally use this method to develop autosamplers. In the prior art, a common autosampler includes a six-way sampling valve, a sampling needle, a metering pump, a quantitative loop, and the li...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N30/24

CPCG01N30/24

Inventor 刘洋

Owner ANHUI WAYEE SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com