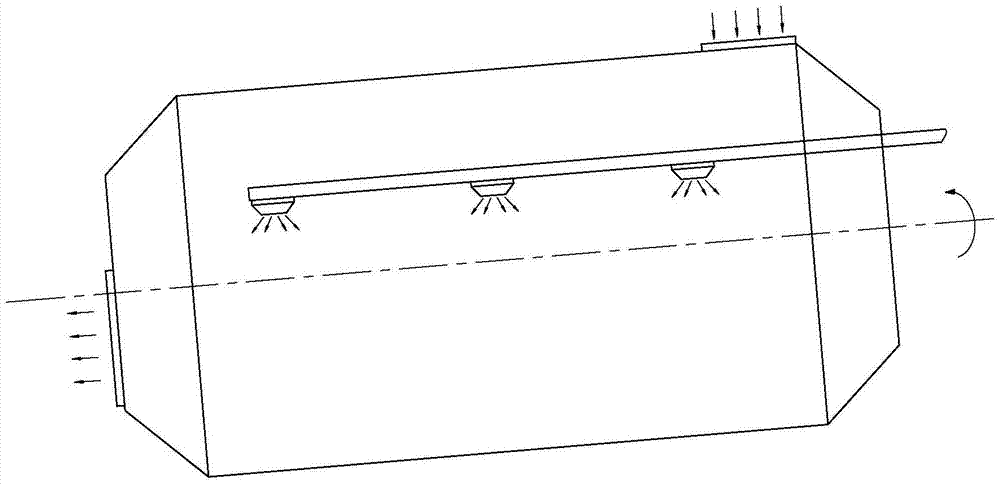

A method for sizing granular materials and a sizing device

A technology of granular materials and materials, applied in the field of surface sizing and spraying of particles, to achieve the effect of being conducive to continuous production, simple structure and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

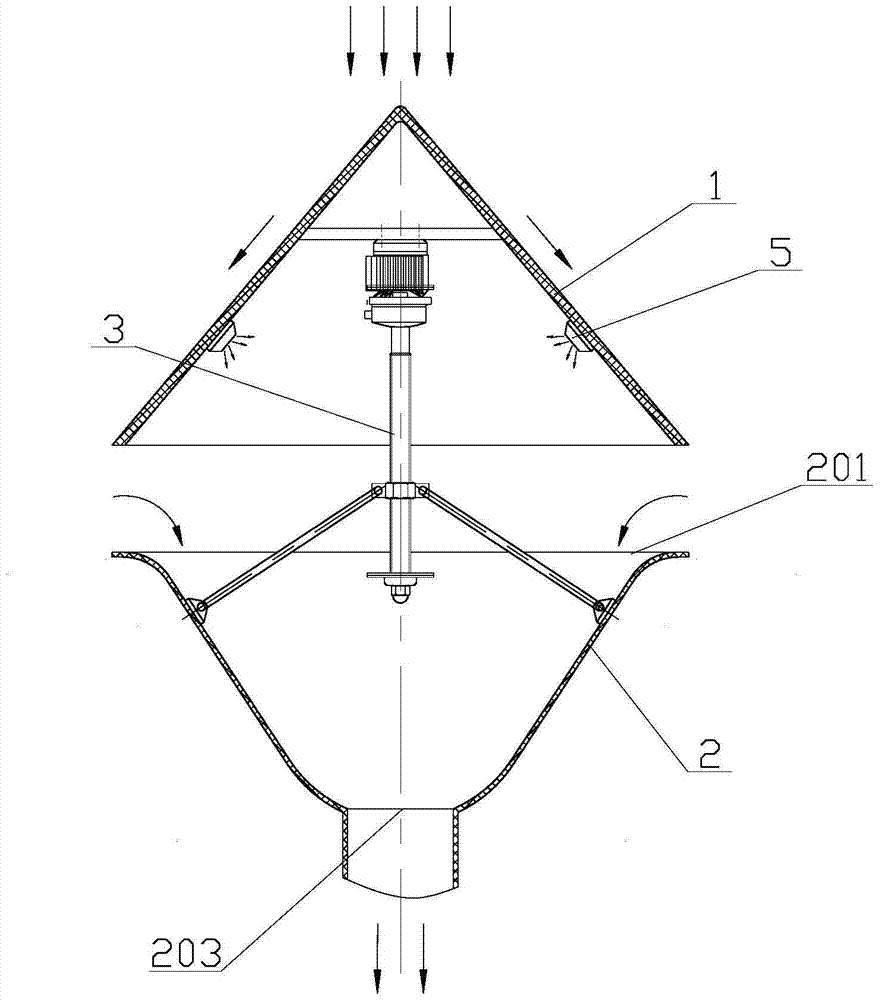

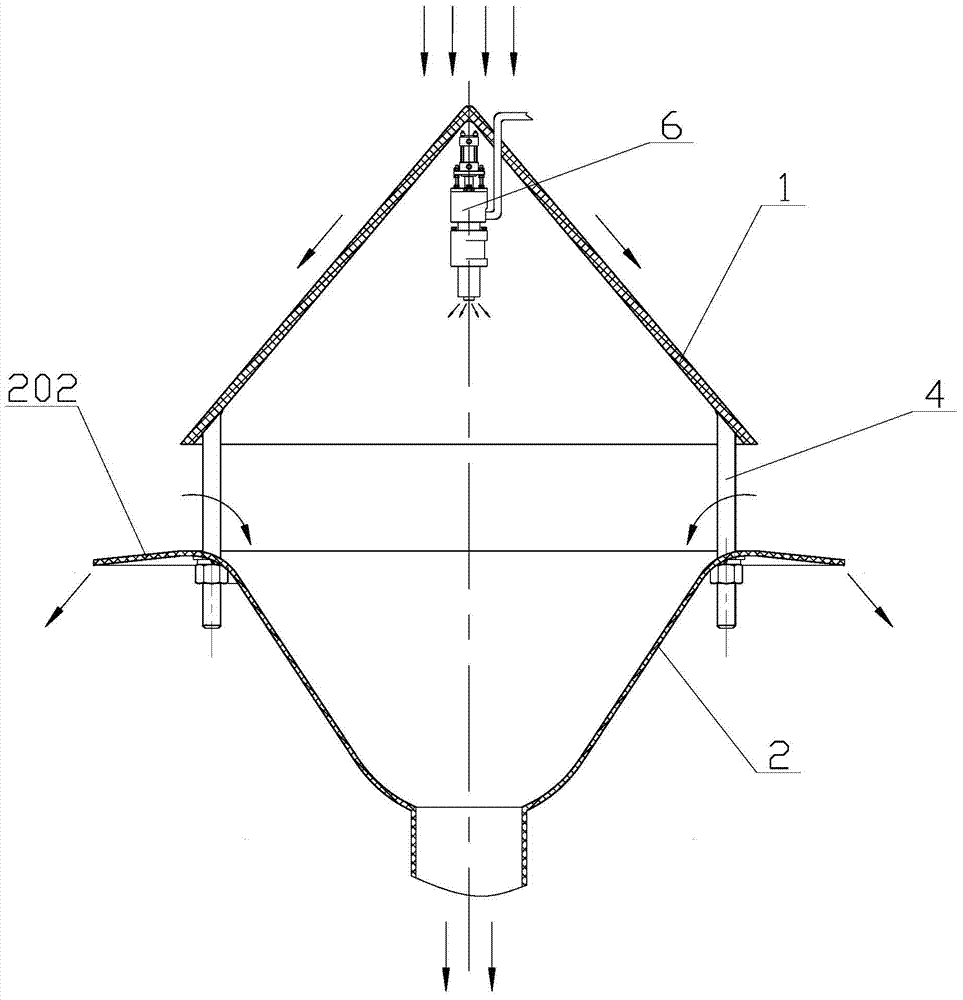

[0055] The present invention will be further described below in conjunction with accompanying drawing.

[0056] A glue sizing method for granular materials: the materials are bundled downward at an initial speed, clustered into a column and continuously unloaded towards the top of the cone; the materials slide down along the cone surface, and the falling materials are gradually increased in diameter The large conical surface spreads thinly and covers the conical surface dynamically in the form of a film until the material slides to the bottom of the cone and continues to fall in the shape of a circular curtain waterfall along the outer edge of the cone bottom; the curtain waterfall-shaped material passes through a negative pressure area during its fall and is subjected to negative pressure Suction, the material particles move laterally to the lower space inside the outer edge of the cone bottom of the cone, and mix with the glue in the space that is sucked down there by negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com