A disassembly method of a car ladder battery module

A battery module and car ladder technology, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve the problems of lack of a relatively complete method for battery packs, low disassembly efficiency, and poor quality of battery cells. Improve cell quality, reduce cost and loss, and avoid cell damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

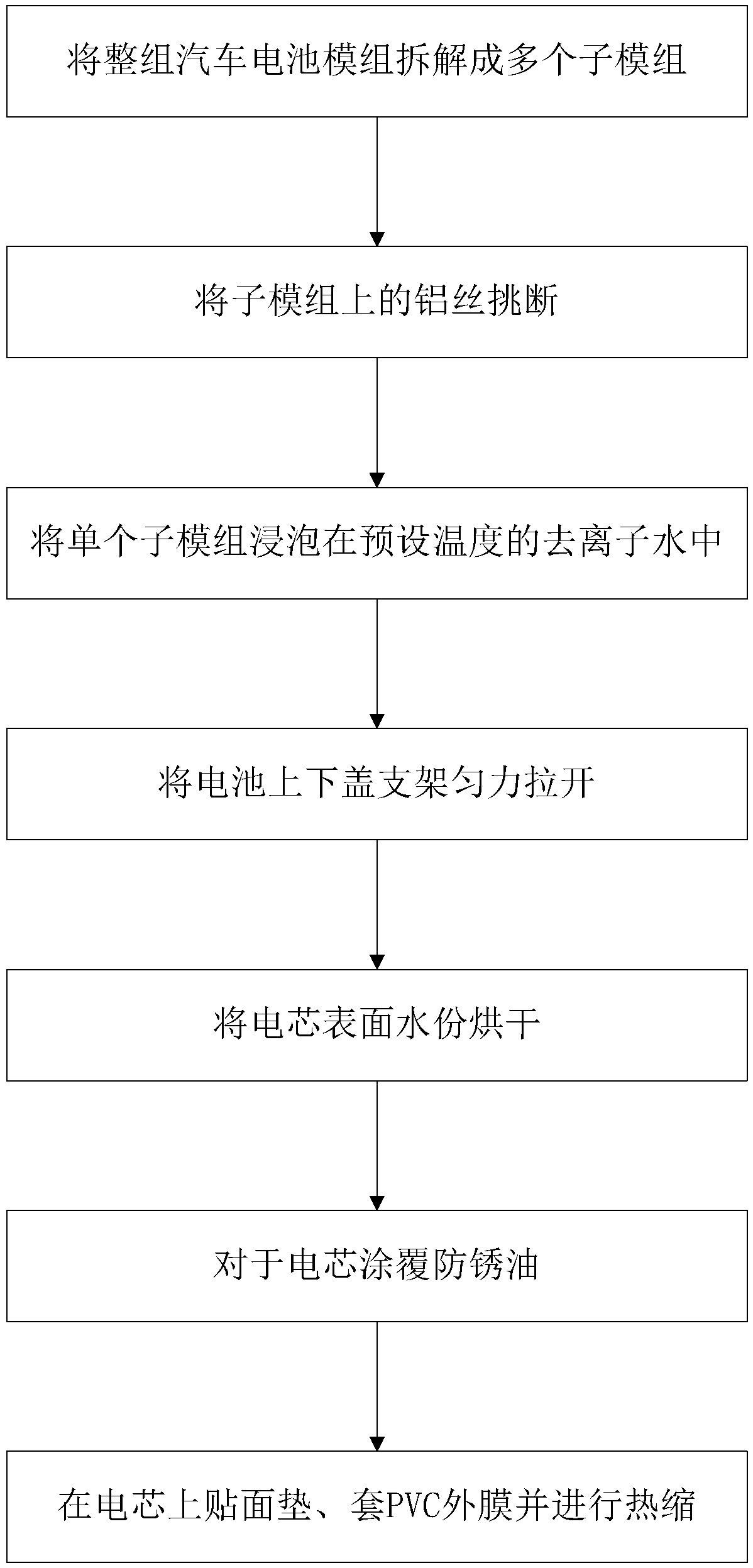

[0015] The invention discloses a dismantling method of an automobile cascade battery module, please refer to figure 1 , which includes the following steps:

[0016] Step S1, dismantling the entire set of vehicle battery modules into multiple sub-modules;

[0017] Step S2, breaking off the aluminum wires between adjacent sub-modules;

[0018] Step S3, immersing a single sub-module in deionized water at a preset temperature;

[0019] Step S4, pull the upper and lower battery cover brackets evenly;

[0020] Step S5, drying the moisture on the surface of the cell;

[0021] Step S6, coating the battery cell with anti-rust oil;

[0022] In step S7, a face pad is placed on the battery cell, a PVC outer film is covered, and heat shrinking is performed.

[0023] The battery for the above method is the aluminum wire welding process automotive cascade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com