Predictive current phase-shifting control method for three-port converter half-switching period sampling

A technology of half switching period and switching period, which is applied in the field of predictive current phase-shifting control of half-switching period sampling of three-port converters, which can solve the problem of inductor current error, different switch on and off times, and affect the safety of the converter. Stable operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

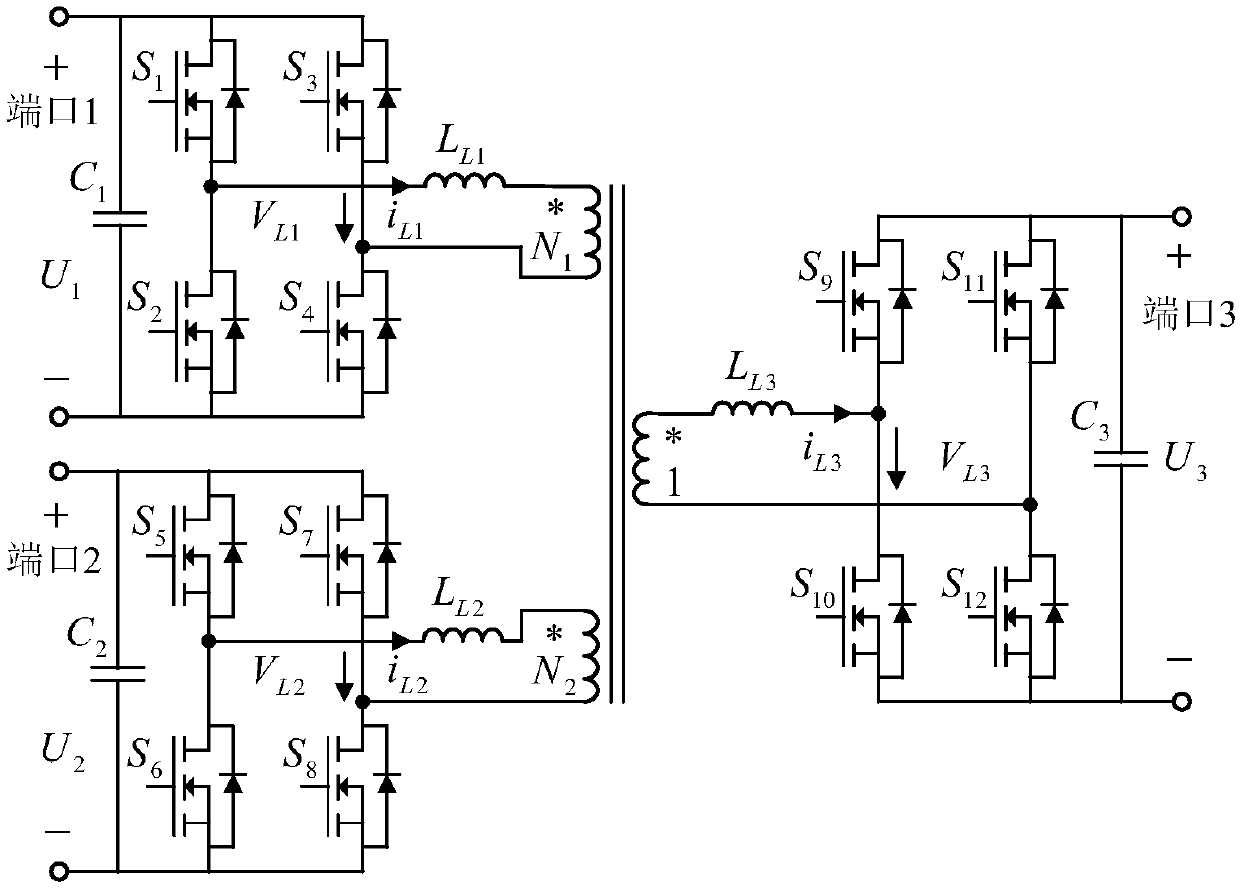

[0081] figure 1 Shown is the topology of the main circuit of the three-port converter in this embodiment. Port 1 is a renewable energy source, port 2 is an energy storage device, and port 3 is a DC bus connected to a load. The load is a generalized load, which can be a load with resistance The capacitive-inductive structure can also be a three-phase AC power grid or a DC micro-grid.

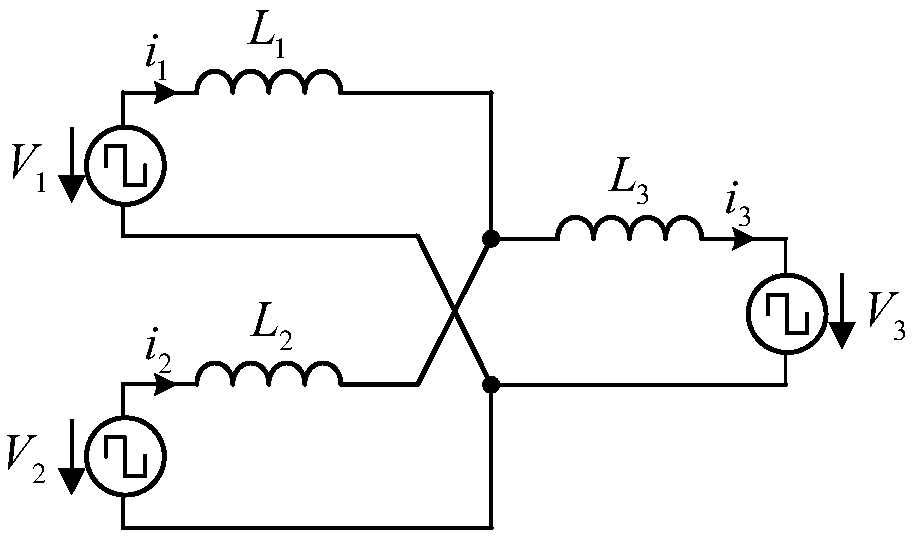

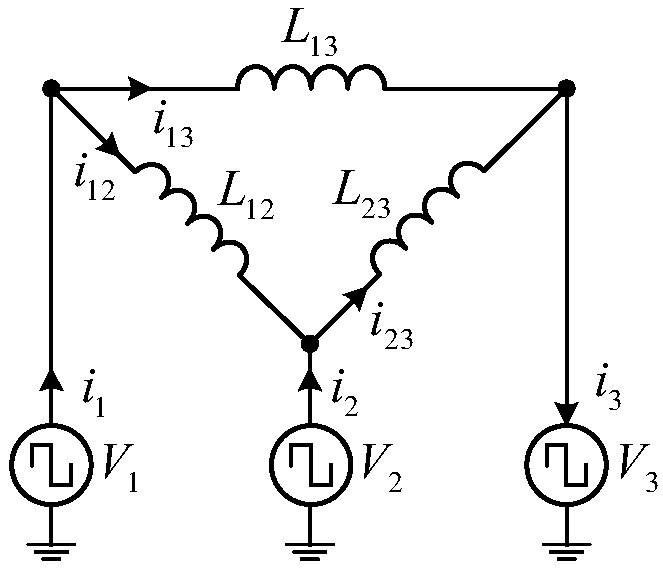

[0082] In this embodiment, the three-port converter adopts phase-shift control, and its port 1, port 2 and port 3 are all full-bridge circuits, and the three-port converter includes a port 1 inductor L L1 , Port 2 inductance L L2 , Port 3 inductance L L3 , and a three-winding transformer.

[0083] In this embodiment, the predictive current phase-shift control method of the half-switching period sampling of the three-port converter is carried out as follows:

[0084] Step 1. Define the shift phase of the three-port converter:

[0085] Set the port 3 drive signal to be the switching frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com