Diaphragm assembly for loudspeaker and loudspeaker provided with same

A technology of a diaphragm assembly and a loudspeaker is applied in the field of loudspeakers to achieve the effects of improving rigidity, reducing the generation of noise, and suppressing stray vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

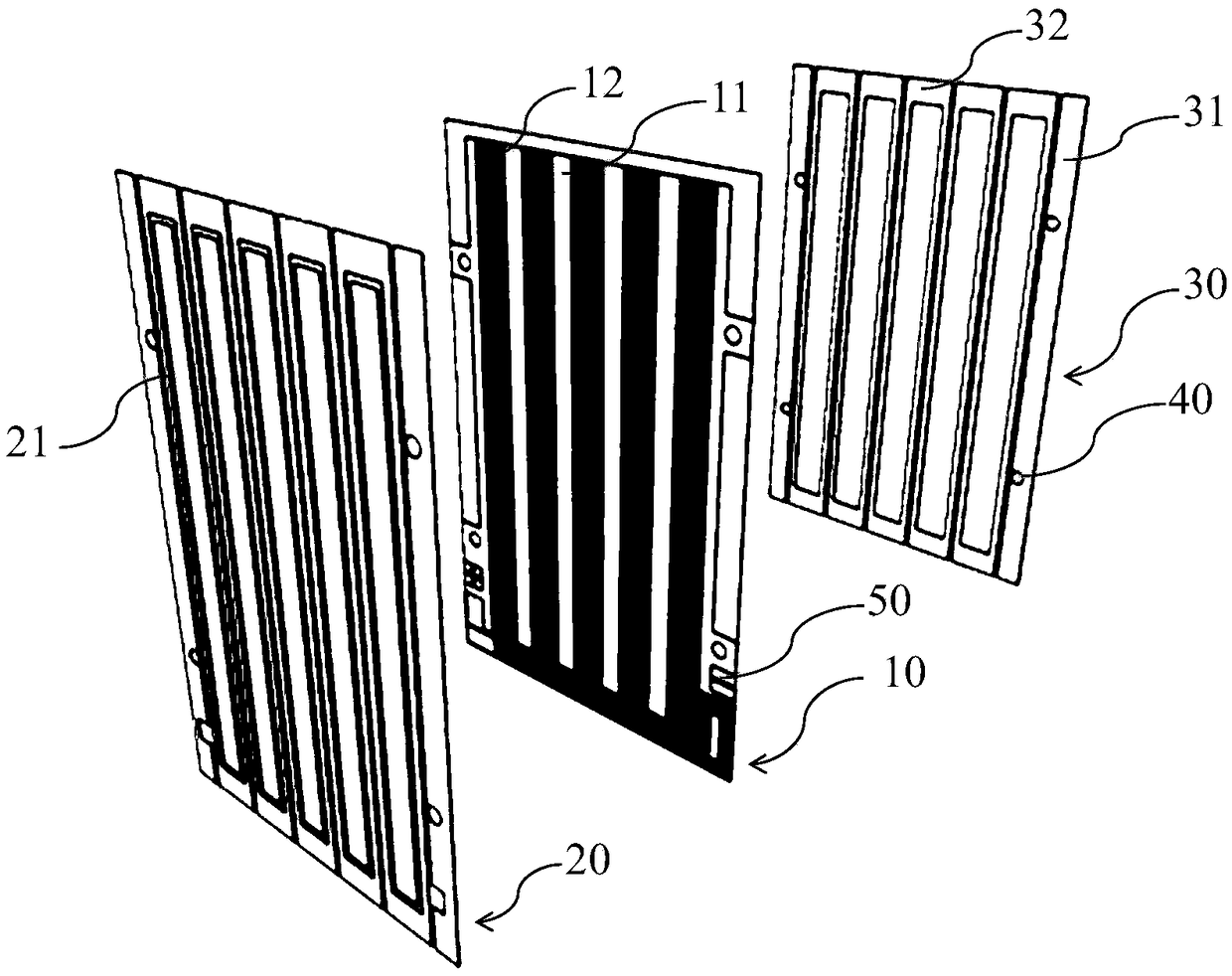

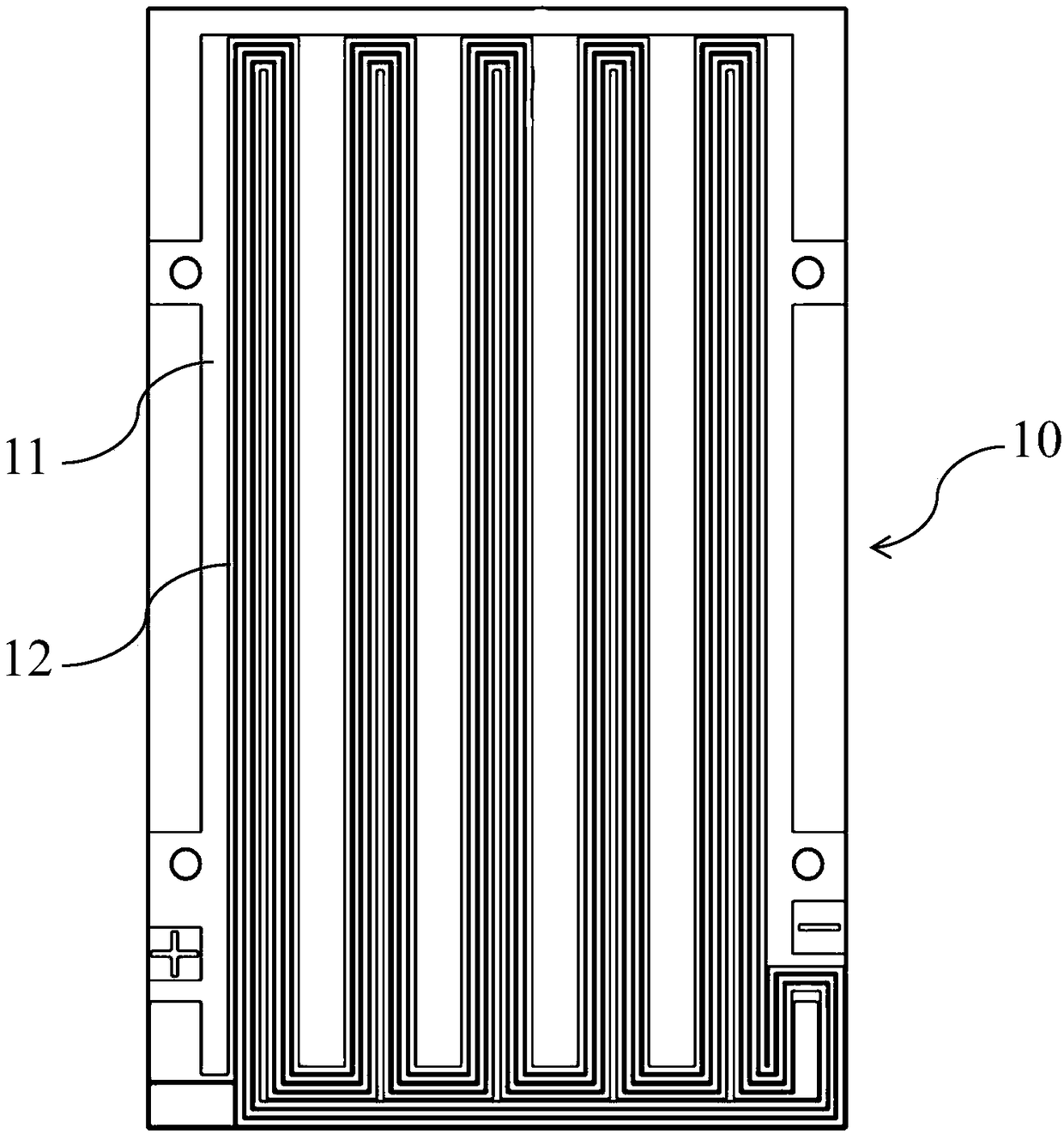

[0049] figure 1 It is a schematic diagram of the overall structure of an embodiment of the present invention. figure 2 for figure 1 The schematic diagram of the three-dimensional explosion structure of the embodiment. image 3 for figure 1 A schematic diagram of the overall structure of the middle flexible circuit board 10 . Such as figure 1 , figure 2 and image 3 As shown, the diaphragm assembly in this embodiment includes a flexible circuit board 10 , a tuning layer 20 and a PCB supporting backplane 30 . Wherein, the PCB supporting backplane 30 is arranged on the back of the flexible circuit board for attaching and assembling the diaphragm assembly to the surface of the mounting seat including the magnetic circuit and the magnetic conductive plate, and the tuning layer 20 is attached to the flexible circuit board 10 s surface.

[0050] In this embodiment, the PCB supporting backplane 30 includes support portions 31 provided at the edges of both sides of the flexib...

Embodiment 2

[0060] Such as Figure 4 As shown, the structure of the diaphragm assembly in this embodiment is suitable for tweeters. Wherein, the flexible circuit board 10 includes a group of conductive loops, and the tuning layer 20 adopts the structural form of spraying ink 22 . Wherein, the structural shape of the sprayed ink 22 can adopt various forms, such as square or ellipse, solid or hollow, and its coverage area on the flexible circuit board 10 can meet the timbre of the tuning tweeter and suppress stray vibration. Setting the spray ink 22 on the surface of the flexible circuit board 10 can effectively suppress the stray vibration of the flexible circuit board 10, reduce noise, and reduce the generation of "beep" sounds; in addition, by spraying the specific shape and area of the ink 722, you can Tunes the subjective timbre of the tweeter.

[0061] The tuning layer 20 in this embodiment is suitable for tweeters by spraying ink 22 , wherein the metal layer 12 includes a set of ...

Embodiment 3

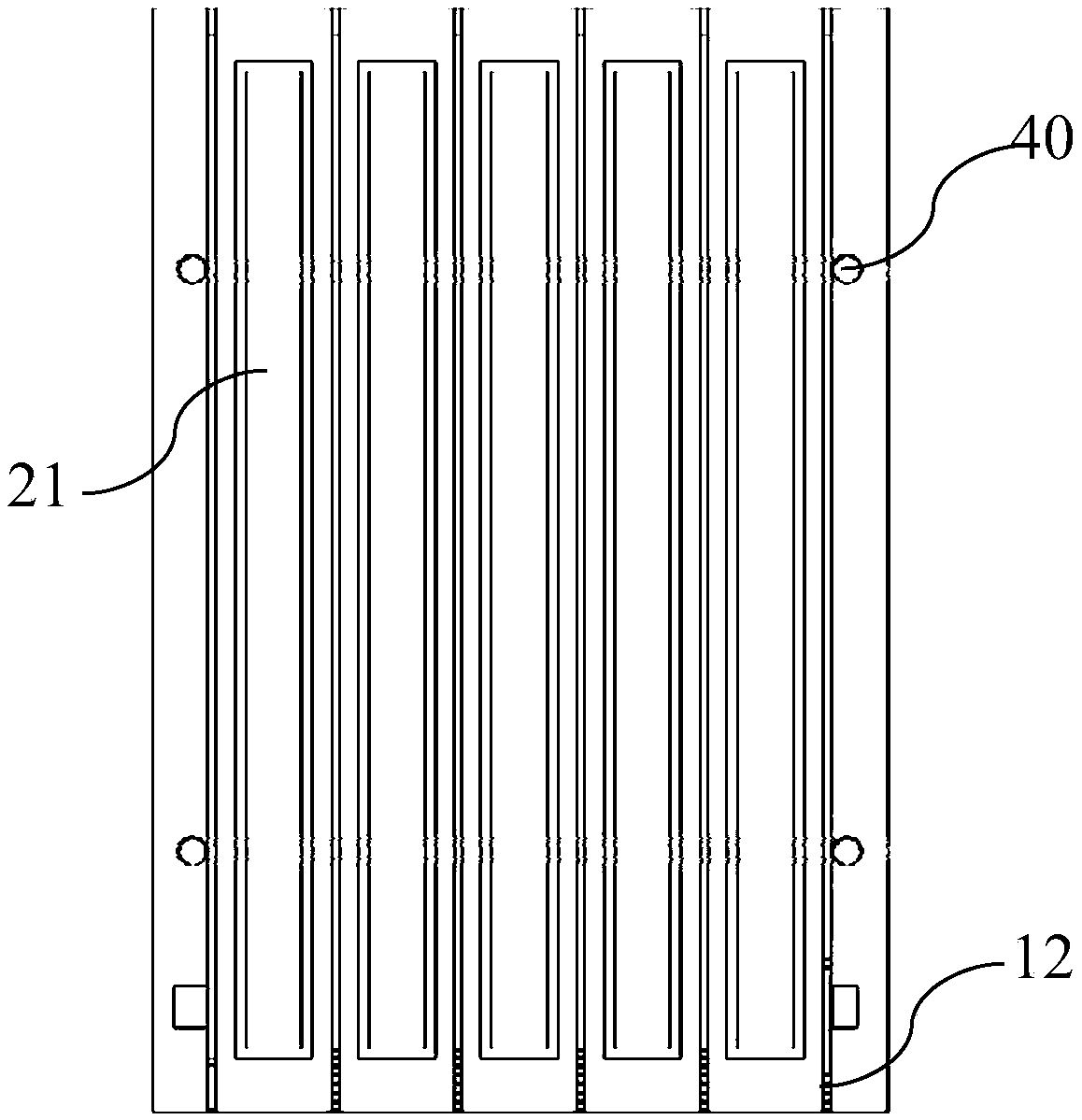

[0063] Such as Figure 5 As shown, the structure of the diaphragm assembly in this embodiment is suitable for a loudspeaker integrating high and midrange. Wherein, two sets of conductive loops are provided on the flexible circuit board 10 , one set of conductive loops corresponds to the high-pitched part, and the other set of conductive loops corresponds to the middle-pitched part. The tuning layer 20 on the conductive circuit of the treble part adopts the structural form of spraying ink 22 , and the tuning layer 20 on the conductive circuit of the midrange part adopts the structural form of a rectangular plate 21 .

[0064] The tuning layer 20 in this embodiment adopts the combination of the sprayed ink 22 and the rectangular plate 21, which can be applied to a loudspeaker integrating high and mid-range, and the flexible circuit board 10 is provided with two sets of conductive circuits. When the treble part and / or the midrange part on the flexible circuit board 10 are corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com