Flattening machine for tea processing

A technology for flattening machine and tea, applied in the direction of tea processing before extraction, etc., can solve the problems of increasing labor intensity, difficulty in pressure adjustment, and increasing difficulty in pressure adjustment, and achieve the effect of reducing labor intensity and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

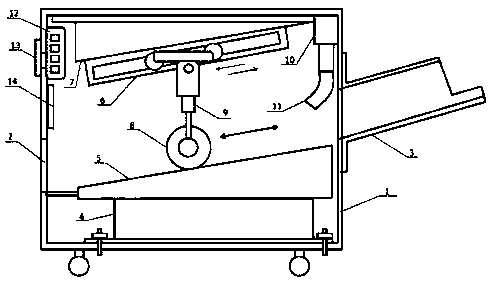

[0018] Embodiment 1 of the present invention: as figure 1 As shown, a flattening machine for tea processing includes a transparent box 1, the lower side of the left end of the transparent box 1 is provided with an outlet 2, and the upper right side of the transparent box 1 is provided with a left lower right side. High-type oblique entrance 3; the transparent box 1 is provided with an oblique rolling device for rolling tea leaves, which can automatically drop the tea leaves towards the direction of the outlet 2. An electric blower 10 with an air outlet vertically downward is provided at the upper right side of the transparent box body 1 . The air outlet of the electric blower 10 is clipped with a universal pipe 11 that can be bent and fixed in any direction.

Embodiment 2

[0019] Embodiment 2: as figure 1 As shown, a flattening machine for tea processing includes a transparent box 1, an outlet 2 is provided on the lower left side of the transparent box 1, and an outlet 2 is provided on the upper right side of the transparent box 1, which is lower on the left and higher on the right. Type oblique entrance 3; At the same time, in the transparent casing 1, there is an oblique rolling device for rolling tea leaves, which can automatically drop the tea leaves toward the outlet 2 direction side. The preferred oblique rolling device includes: a base 4 that is detachably mounted on the bottom surface of the transparent box body 1, the upper end of the base 4 is welded with an inclined rolling platform 5 that is low in the left and high in the right, and includes an electric Reciprocating mechanism 6, an inclined-plane connecting plate 7, a rolling roller 8, and an electric telescopic mechanism 9. In the above structure, the inclined-plane connecting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com