A drilling fluid mixing and cleaning stirring device and its control method

A technology of a stirring device and drilling fluid, which is applied in the field of drilling engineering, can solve the problems of high output power of the motor, limited conveying capacity of the impeller, and troublesome process, and achieves the effect of enhancing the conveying capacity and the mixing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

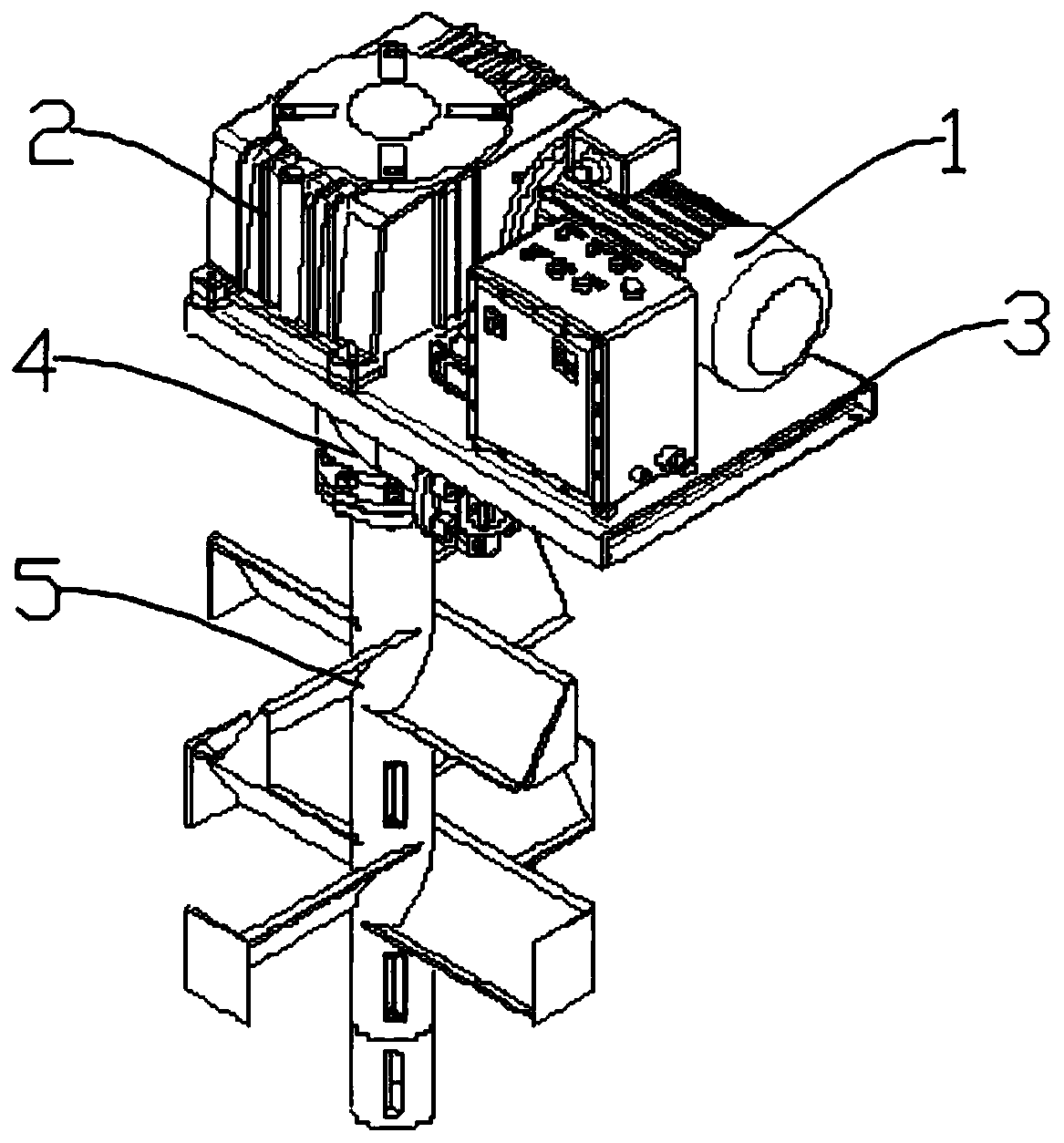

[0049] Such as Figure 1-Figure 4 and Figure 9 As shown, a drilling fluid mixing and cleaning stirring device includes a driving transmission mechanism, a base 3 and a liquid inlet stirring mechanism, the driving transmission mechanism is arranged on the upper surface of the base 3, and the liquid inlet stirring mechanism is arranged on the lower surface of the base 3 , and the liquid inlet stirring mechanism is connected with the drive transmission mechanism; the drive transmission mechanism includes an explosion-proof motor 1 and a gearbox 2 that are fixedly arranged on the upper surface of the base 3, the explosion-proof motor 1 is connected with the gearbox 2, and the explosion-proof motor 1 is connected with the gearbox 2. The output shaft of the gearbox 2 passes through the base 3 and is connected to the liquid inlet stirring mechanism; the liquid inlet stirring mechanism includes a mixing transmission device 4 and a stirring rod 5, and the mixing transmission device 4 ...

Embodiment 2

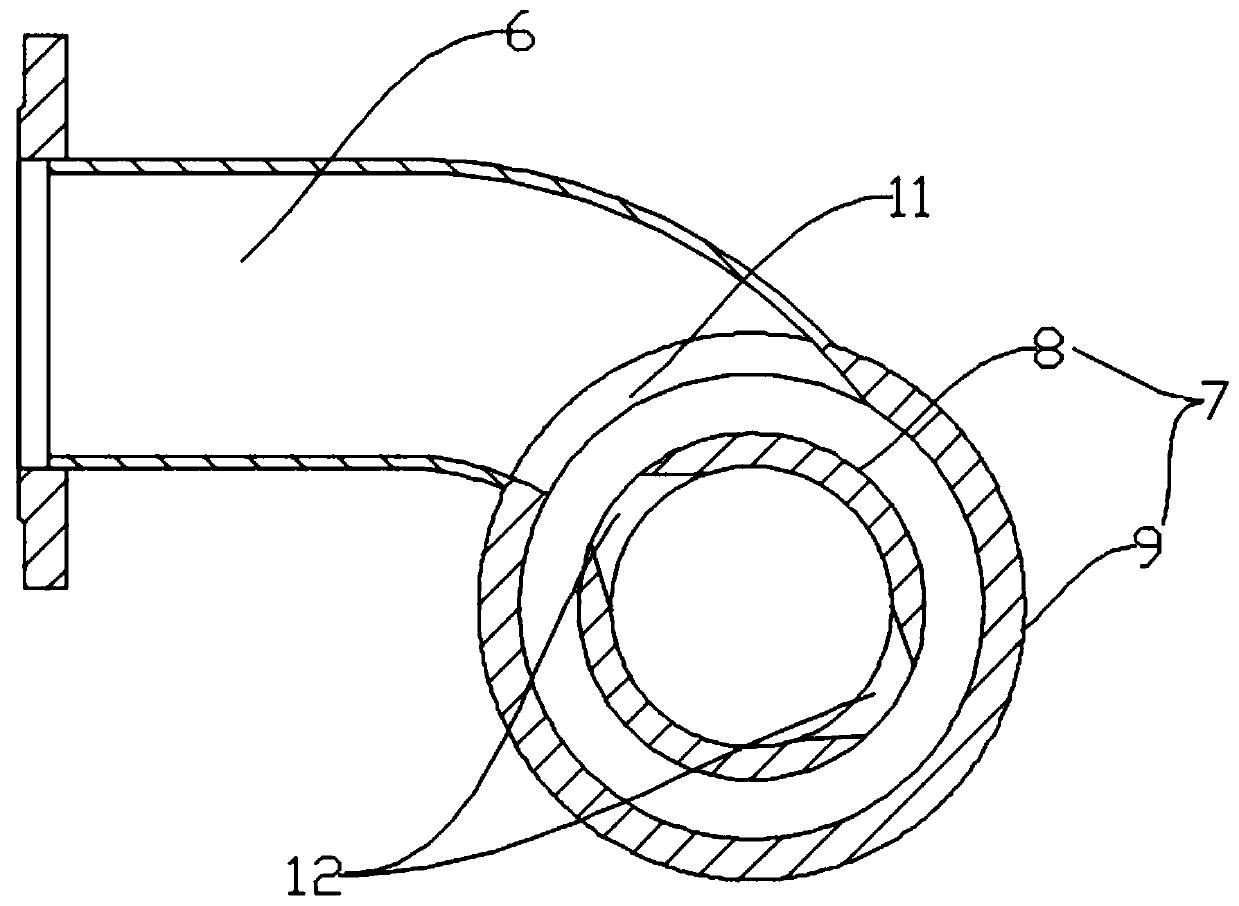

[0052] Such as Figure 4 As shown, in this embodiment, on the basis of Embodiment 1, a plurality of second liquid inlets 12 are evenly opened on the side wall of the inner rotating body 8 , and between the outer wall of the inner rotating body 8 and the inner wall of the outer casing 9 A cavity 15 is provided. There are multiple second liquid inlets 12, which can enhance the liquid inlet efficiency in the inner rotating body 8. At the same time, a cavity 15 is set between the inner rotating body 8 and the outer shell 9, which further increases the liquid intake in the inner rotating body 8. The liquid feeding rate increases the speed of mixing and agitation.

Embodiment 3

[0054] Such as Figure 5-Figure 7 As shown, this embodiment is based on Embodiment 2. The stirring rod 5 includes a first liquid inlet shaft tube 17, and an impeller group is connected to the first liquid inlet shaft tube 17. The first liquid inlet shaft tube 17 A plurality of spray slits 18 are evenly opened on the top, and the liquid outlet direction of the spray slits 18 is the same as the direction of the stirring working surface of the impeller. The layer hole 28 and the outer layer hole 29 on the outer pipe wall of the first liquid inlet shaft tube 17, the first upper edge 30 of the inner layer hole 28 is vertically higher than the second upper edge 31 of the outer layer hole 29, and the inner The first lower edge 32 of the layer hole 28 is vertically higher than the second lower edge 33 of the outer layer hole 29 .

[0055] By setting the spray slot 18, the previous way of setting the nozzles has been changed, which can better achieve the effect of cleaning the grit. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com