Raw material crushing device for rubber production

A raw material crushing and rubber technology, applied in grain processing, etc., can solve the problems of low rubber material quality, affecting the quality of rubber materials, and unable to meet production needs, etc., to achieve good crushing effect, better effect, and pollution prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

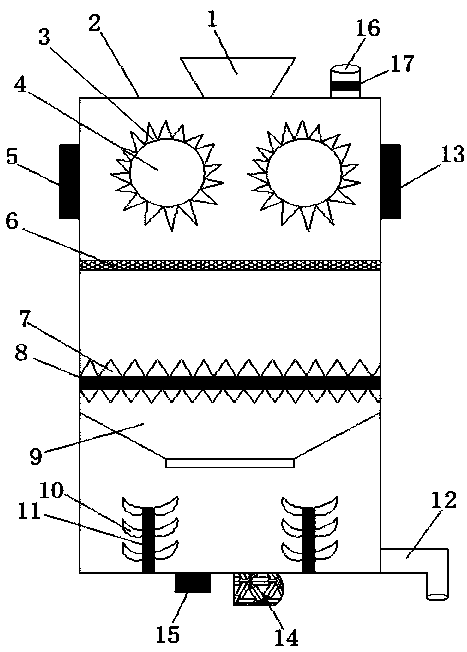

[0015] Embodiment 1: see figure 1 , a raw material crushing device for rubber production provided by the patent of the present invention is now described, including a crushing box 2, a filter plate 6 and a stirring shaft 8, and the filter plate 6 and the stirring shaft 8 are arranged inside the crushing box 2, so A feed hopper 1 is arranged above the pulverizing box 2, and a stirring wheel 4 is arranged above the filter plate 6 in the pulverizing box 2, and a first stirring gear 3 is provided on the surface of the stirring wheel 4, and a stirring wheel 3 is arranged below the filter plate 6. A stirring shaft 8 is provided and a second stirring gear 7 is arranged on the surface of the stirring shaft 8, a hopper 9 is arranged below the stirring shaft 8, a stirring rod 11 is arranged below the hopper 9 and a third stirring rod 11 is arranged on the stirring rod 11. Stirring gear 10, a discharge pipe 12 is provided on the side of the bottom end of the crushing box 2.

Embodiment 2

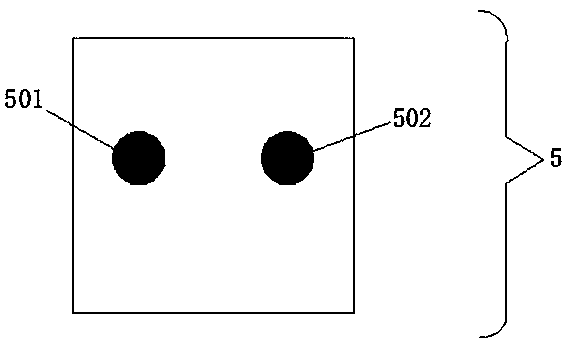

[0016] Example 2: see figure 1 with 2 , A raw material crushing device for rubber production provided by the patent of the present invention is now described. A control panel 5 is provided on one side of the crushing box 2, and the control panel 5 is provided with a switch button 501 and an emergency stop button 502.

Embodiment 3

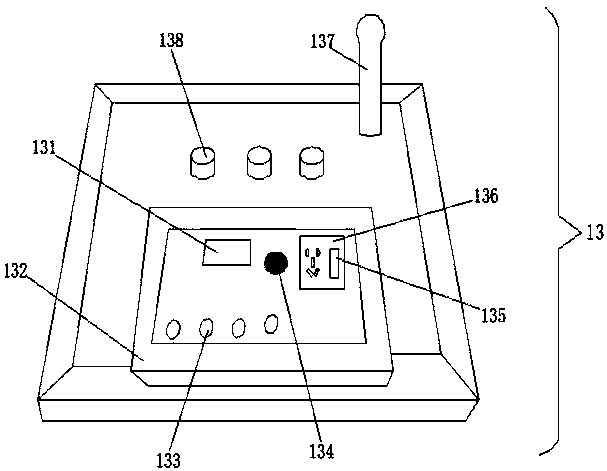

[0017] Embodiment 3: see figure 1 with 3 Now, a raw material crushing device for rubber production provided by the patent of the present invention is described. The other side of the crushing box 2 is provided with a temperature regulating device 13, and the temperature regulating device 13 includes a regulating shell 132, a temperature sensor 137 and Control button 138 , the surface of the adjustment shell 132 is provided with a display screen 131 , an adjustment button 133 , a warning light 134 , a switch button 135 and a power socket 136 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com