Welding overturning machine

A technology of flipping machine and flipping components, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increasing the labor intensity of construction personnel, wasting human resources, affecting the progress of construction, etc., and saving raw materials. Cost, labor saving, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is further described below in conjunction with accompanying drawing and embodiment:

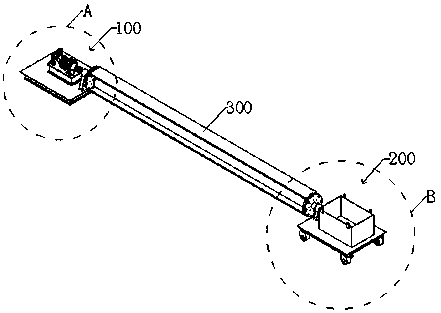

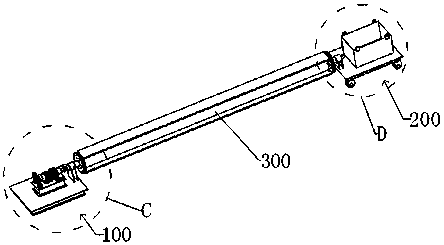

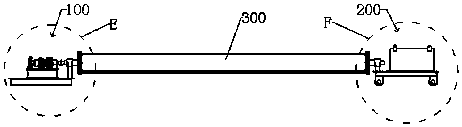

[0038] like Figure 1-3 As shown, a welding turning machine includes a turning component 100 and a shifting component 200 , and a weldment 300 is laid between the turning component 100 and the shifting component 200 .

[0039] like Figure 4-6 As shown, the turning assembly 100 includes a turning platform 110 , a motor 120 and a first support arm 150 , and the motor 120 is connected to a turning controller (not shown in the figure, the same below). In this embodiment, the rear side of the motor 120 is connected to the brake 170, the brake 170 includes a brake cylinder 171 and a brake wheel 173, the brake cylinder 171 is connected to the brake pad through the brake connector 172, and the brake pad is sleeved on The outer side of the brake wheel 173. Preferably, the brake 170 further includes a brake spring 174 , the brake spring 174 is sleeved on the brake conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com