Rotary fully-flexible mechanical arm

A flexible manipulator, manipulator technology, applied in manipulators, program-controlled manipulators, claw arms, etc., to achieve the effect of broad application prospects and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

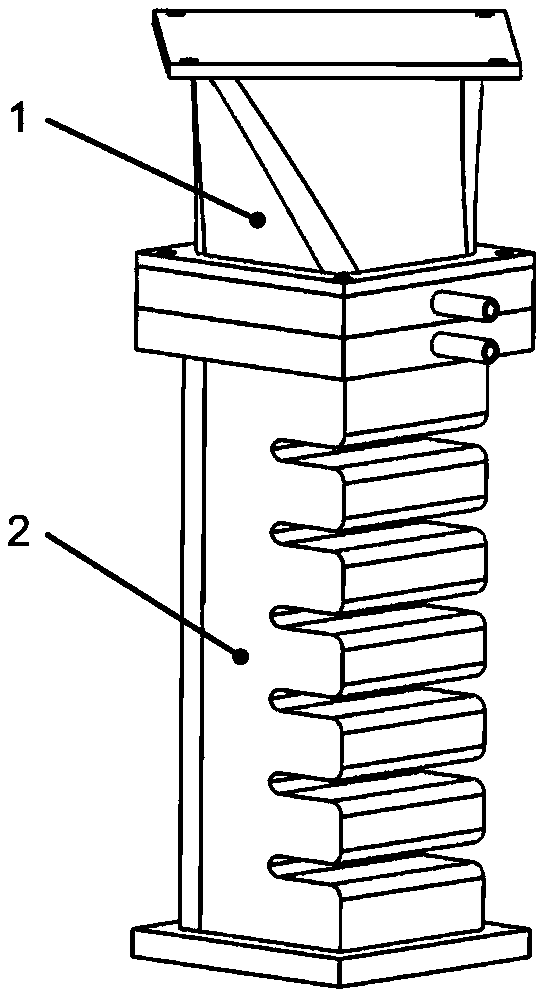

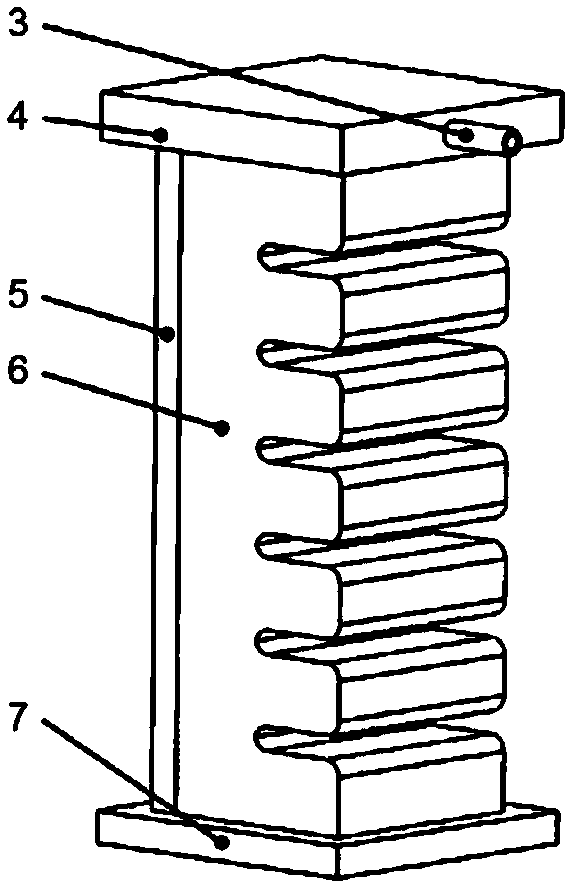

[0027] The joint silicone tube 8 of the present invention is connected to negative pressure, and the side curved surface 11 positively twists to drive the flexible joint 1 to rotate, and the lower bottom surface of the joint connection module 9 of the flexible joint 1 and the upper bottom surface 4 of the mechanical arm connection module 4 of the flexible mechanical arm 2 move synchronously , to drive the flexible manipulator 2 to rotate, and then bend to different directions by controlling the flexible manipulator 2 to receive positive pressure and negative pressure. The combination of the flexible joint 1 and the flexible manipulator 2 makes the motion of the flexible manipulator 2 change from a planar two-dimensional motion to a three-dimensional motion in space, which improves the range of motion and flexibility of the manipulator.

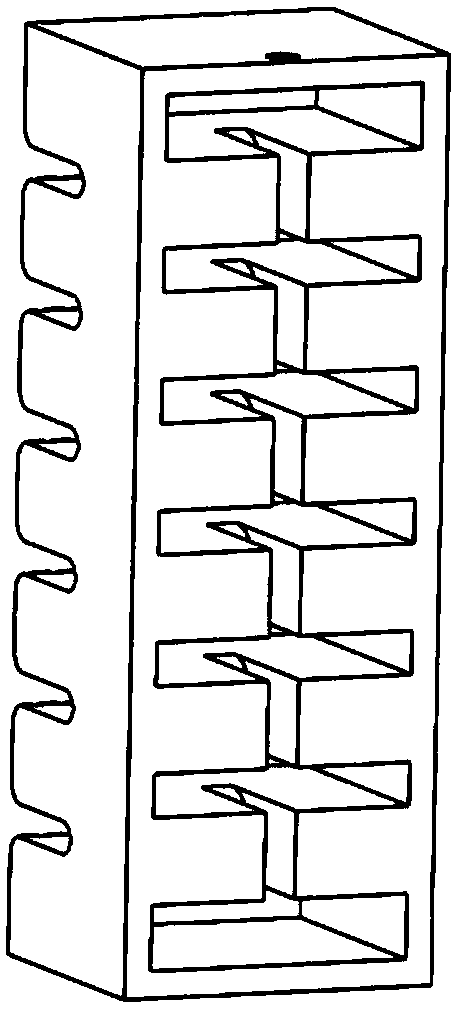

[0028] Such as Figure 5 As shown, after the silicone tube 3 of the manipulator is connected to the positive pressure, the main body 6 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com