Planetary gear transmission and screw rod advancing and retreating chip-free cutting machine

A planetary gear transmission, advancing and retreating knife technology, applied in metal processing and other directions, can solve the problems of high manufacturing cost, increased labor intensity and inconvenient operation of Huff clamping blocks, saving the time of replacing clamping blocks and improving efficiency , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

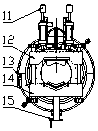

[0009] like figure 1 As shown, the chipless cutting machine of the present invention includes a frame, a turntable disposed on the frame, a clamping device 1, a drive motor 2 for driving the turntable to rotate, and a mechanical cutting device 3 disposed on the turntable. like figure 2 As shown, the clamping device 1 includes an upper clamping block 12, a lower clamping block 14, an adjusting hand wheel 15, a cylinder 11 and a pipe specification dial 13, the upper clamping block 12 is connected with the cylinder 11, and the lower clamping block 14 is connected with the adjusting hand wheel. The wheels 15 are connected, and the pipe specification dial 13 is located at the lower part of the upper and lower clamping blocks. The upper and lower clamping blocks are V-shaped clamping blocks.

[0010] The working principle of the present invention is: after the cutting machine receives the cutting signal, the clamping device 1 clamps the pipe and sends it to the cutting device for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com