Vacuumizing assisted double-color injection moulding device

A two-color injection molding and vacuuming technology, applied in the field of mold injection molding production, can solve the problems of product appearance peeling, packaging material waste, shrinkage, etc., to achieve the effect of increasing production capacity and yield rate, and reducing personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

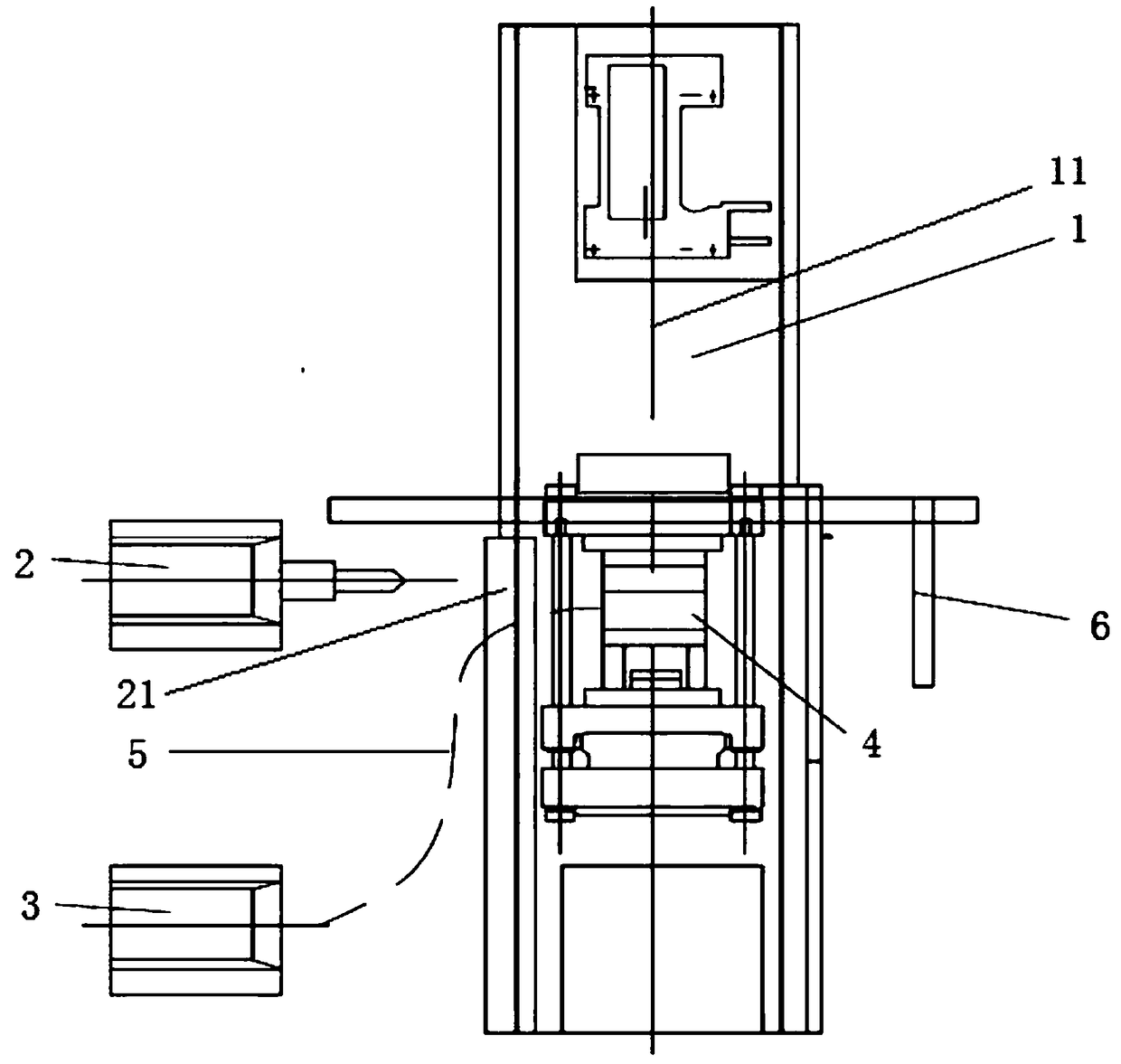

[0017] The invention discloses a vacuum-assisted two-color injection molding device, such as figure 1 As shown, the pressure measuring device includes an injection molding machine 1, a two-color overmolding machine 2 and a vacuum pump 3, and the injection molding machine 1 is a single-color injection molding machine. The injection molding machine 1 is provided with a mold 4, the mold 4 includes a front mold and a back mold, and the front mold and the back mold cooperate to form a mold cavity for injection molding. The injection molding machine 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com