Tread pattern structure of special all-steel radial tire for rainy season

A radial tire and tread pattern technology, applied in the field of tire patterns, can solve the problems of reduced driving safety, less all-steel radial tires, reduced braking distance or anti-skid ability, etc., to improve safety performance and reduce sideslip. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

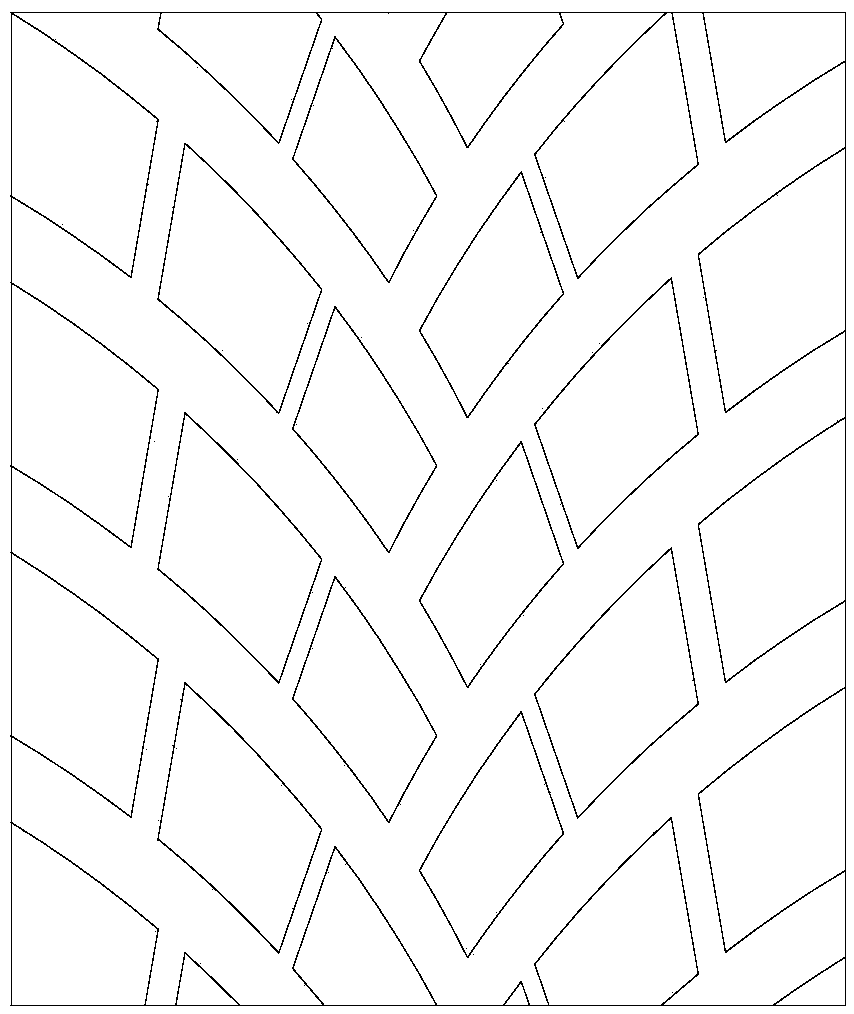

[0017] Such as Figure 1-3 As shown, the tread pattern structure of the all-steel radial tire dedicated for the rainy season is characterized in that it includes several groups of left-right symmetrical curved pattern blocks 1, each group of curved pattern blocks 1 is arranged in a herringbone shape, and each group of curved pattern blocks 1 forms a Consistent orientation.

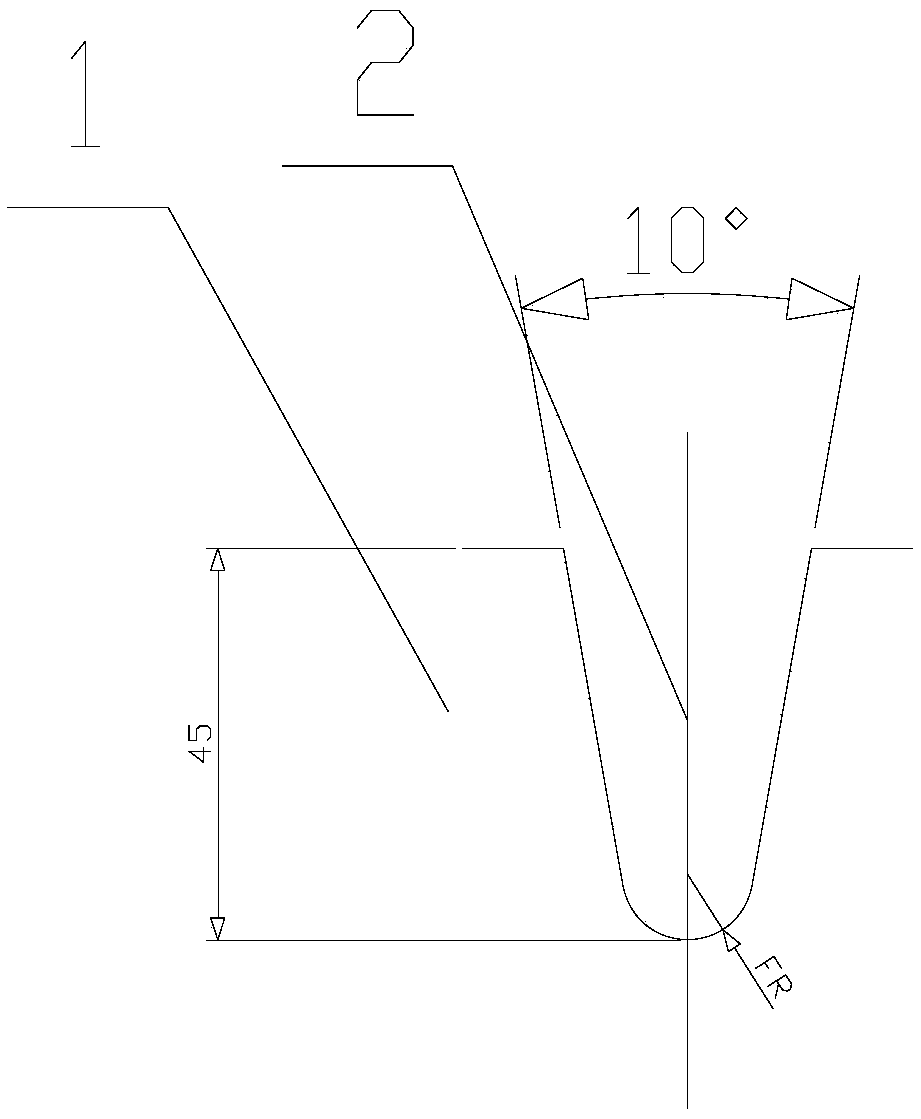

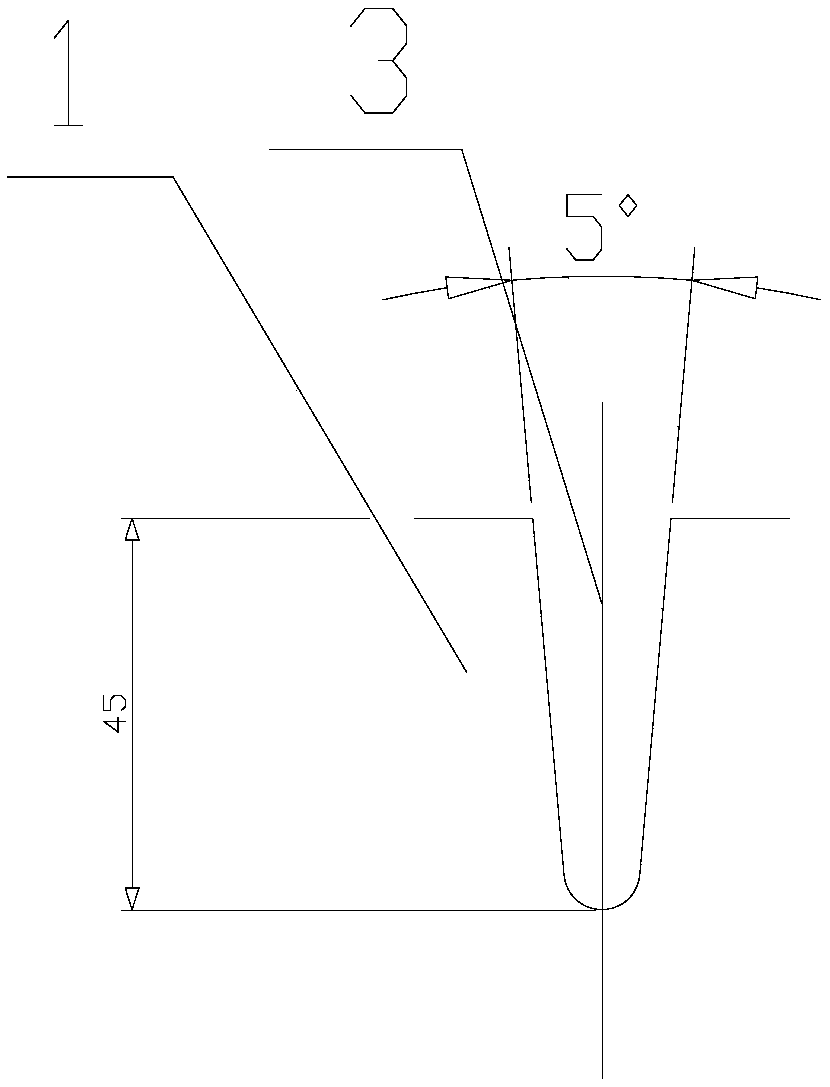

[0018] Each set of curved pattern blocks 1 arranged in a herringbone shape is provided with main grooves 2 , and each group of curved pattern blocks 1 is provided with auxiliary pattern grooves 3 .

[0019] The tread pattern structure of the tire is a single-guided pattern structure.

[0020] The curved pattern block 1 is a quadrilateral structure, each side is arc-shaped, and the angle formed between the sides is an acute angle.

[0021] Both sides of the curved pattern blocks 1 arranged in a herringbone shape have the same radian.

[0022] The groove widths of the main groove 2 and the auxiliary groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com