Slideway device for conveying heavy equipment

A technology of heavy equipment and slideway, which is applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc. It can solve the problems of high labor intensity, low safety factor, and accidental damage to heavy equipment, so as to reduce labor intensity and avoid the center of gravity Unstability, safety-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

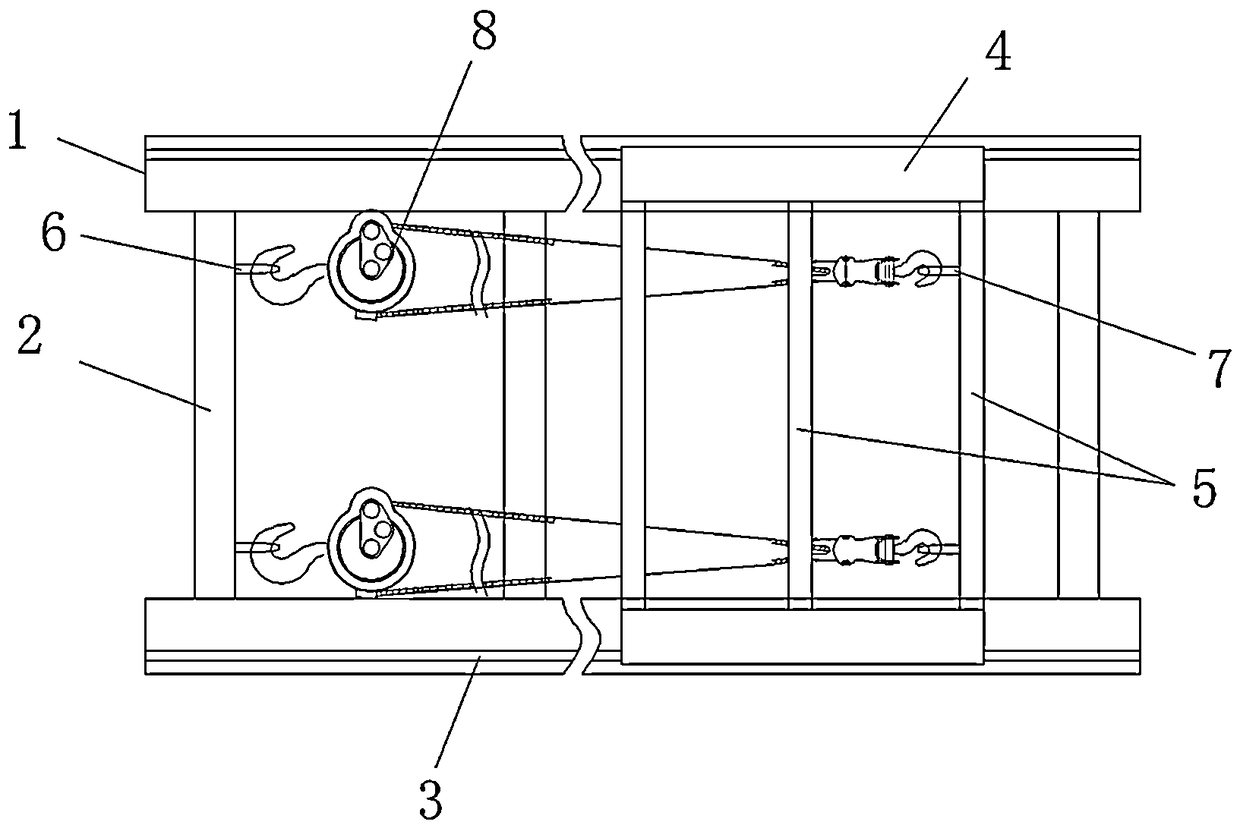

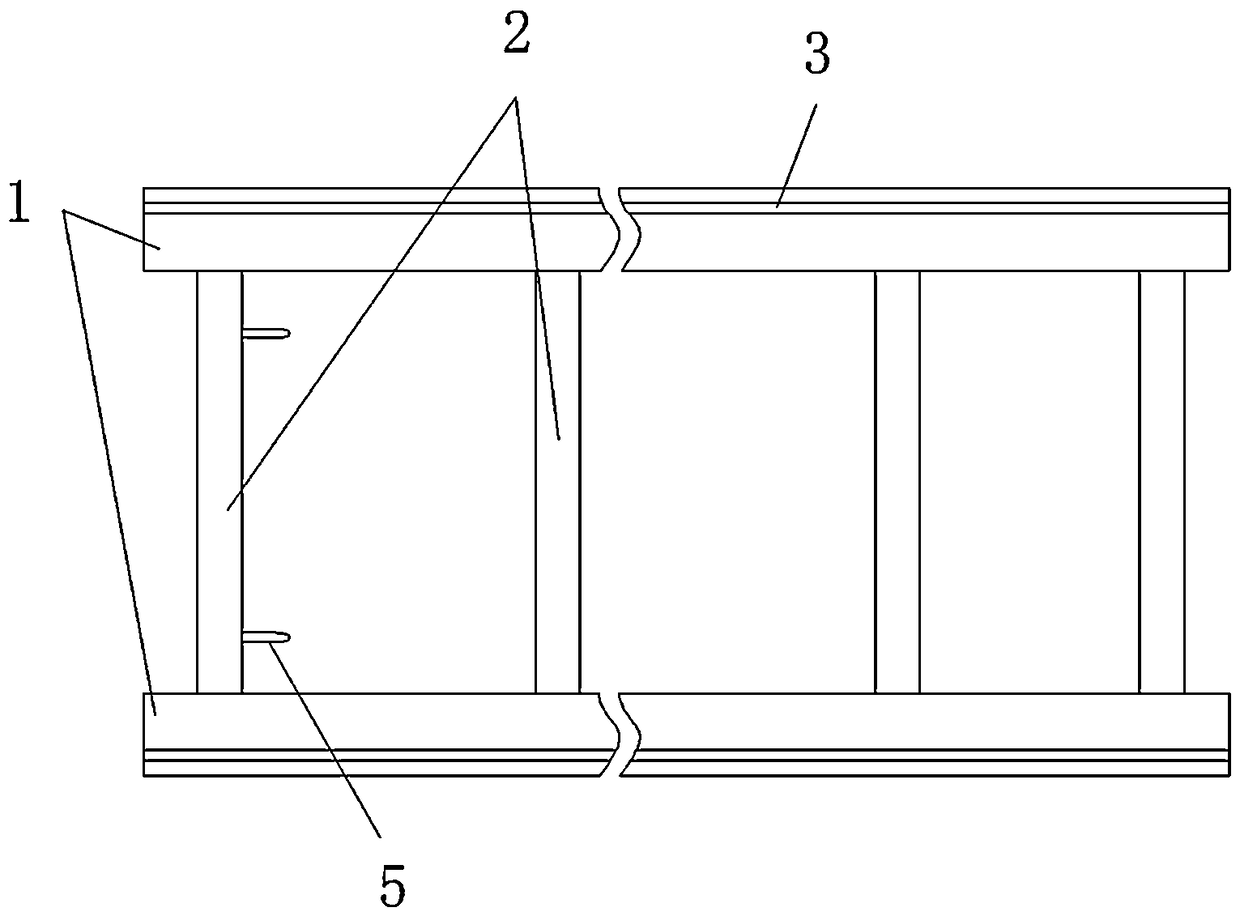

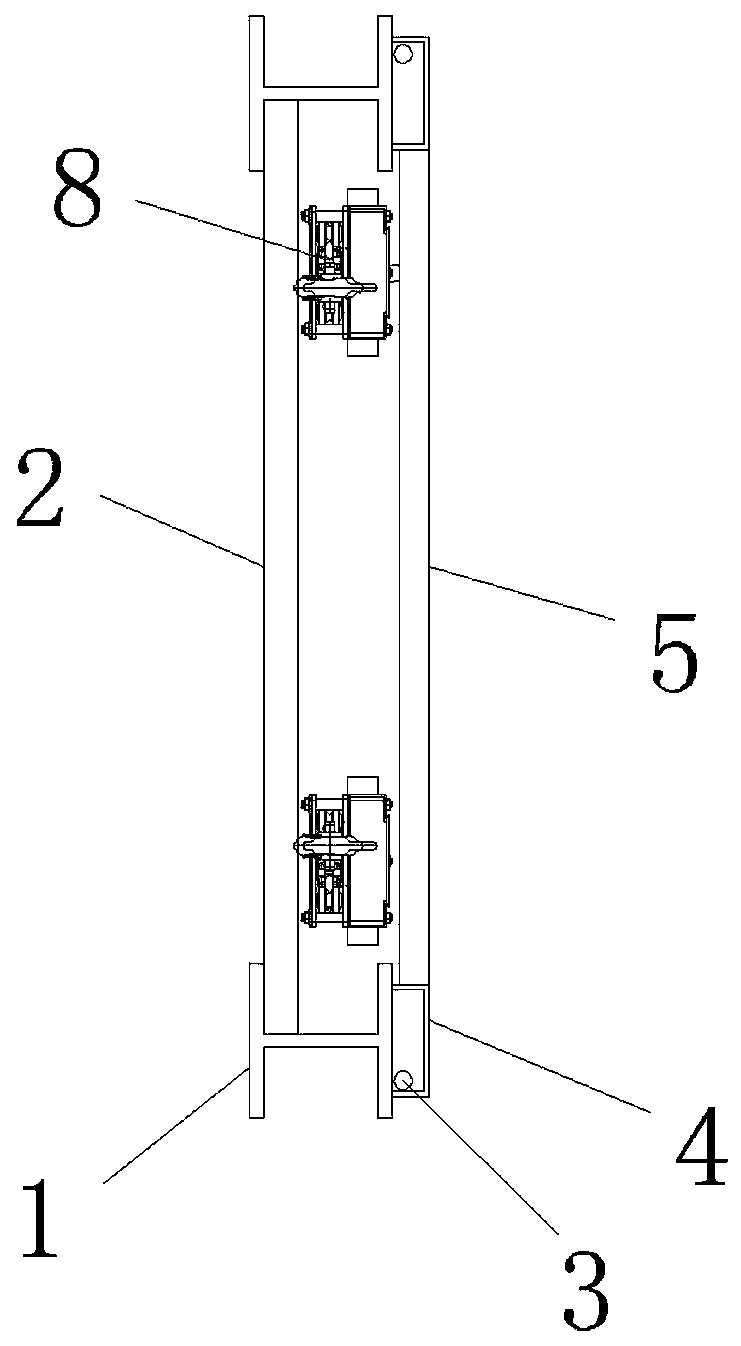

[0014] combine Figure 1~3 As shown, the present invention provides a slideway device for transporting heavy equipment, including a slideway base and a support bracket arranged on the top of the slideway base; the slideway base includes two slide rails 1 arranged in parallel and spaced apart, The slide rail 1 can be made of I-shaped steel, and the two slide rails 1 are fixedly connected by a set of longitudinal connecting rods 2. The tops of the two slide rails 1 are respectively provided with guiding ribs 3 along the axial direction; the supporting bracket includes Two crossbeams 4 arranged at intervals are fixedly connected by a group of longitudinal beams 5, and the two crossbeams 4 correspond to two slide rails 1 respectively; preferably, the slide rails 1 are 15mm wider than the crossbeam 4.

[0015] The crossbeam 4 is in the shape of "冂" with the opening downward; the opening of the crossbeam 4 cooperates with the guiding rib 3; preferably, the guiding rib 3 is located i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com