Automatic tightening device for pumping rod sealing device

A polished rod sealer, automatic technology, applied in the direction of sealing/packing, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of cumbersome management and heavy workload, reduce management work, prevent wellhead oil leakage, Manageable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

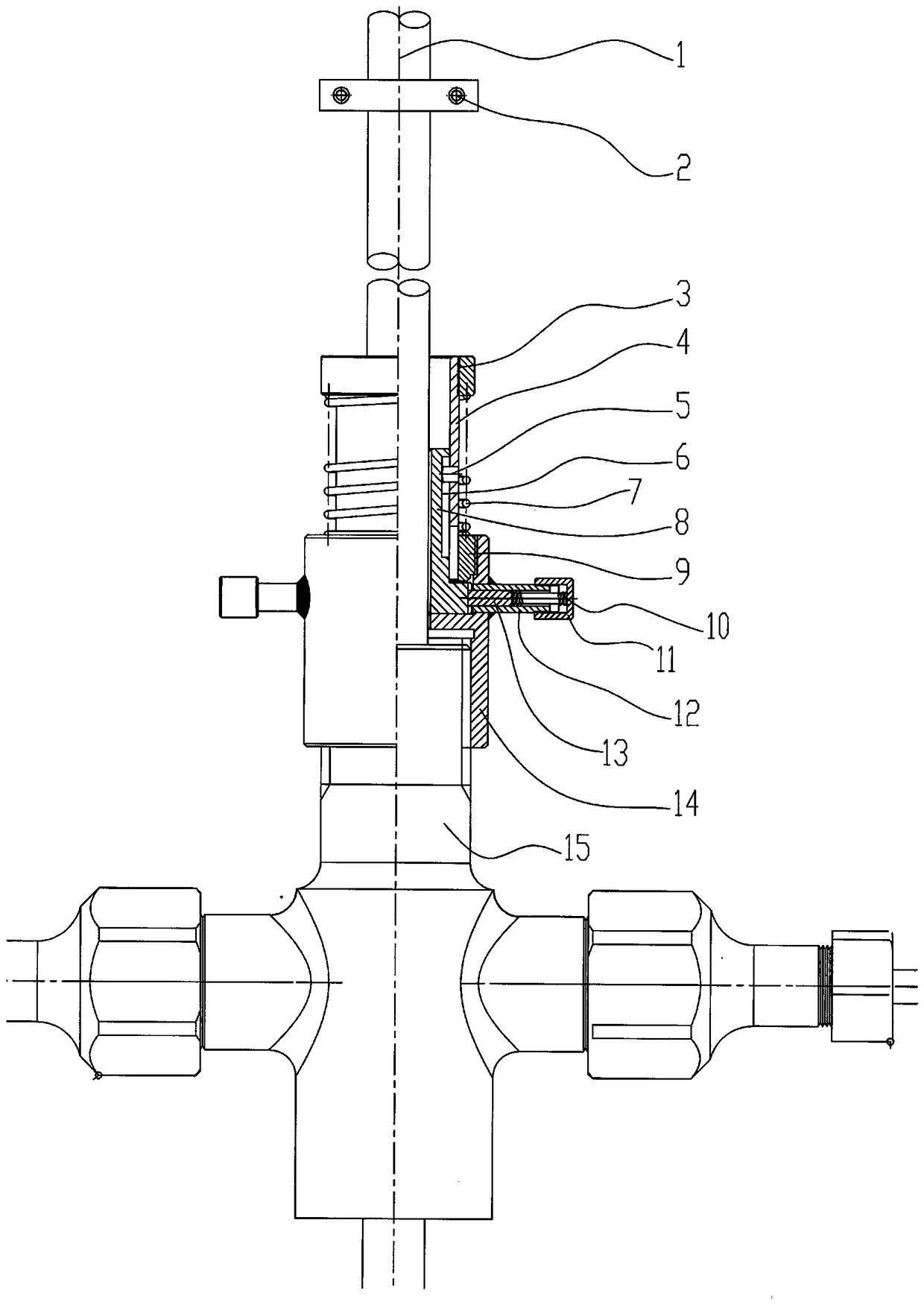

[0009] Attached below figure 1 Embodiments of the present invention will be described.

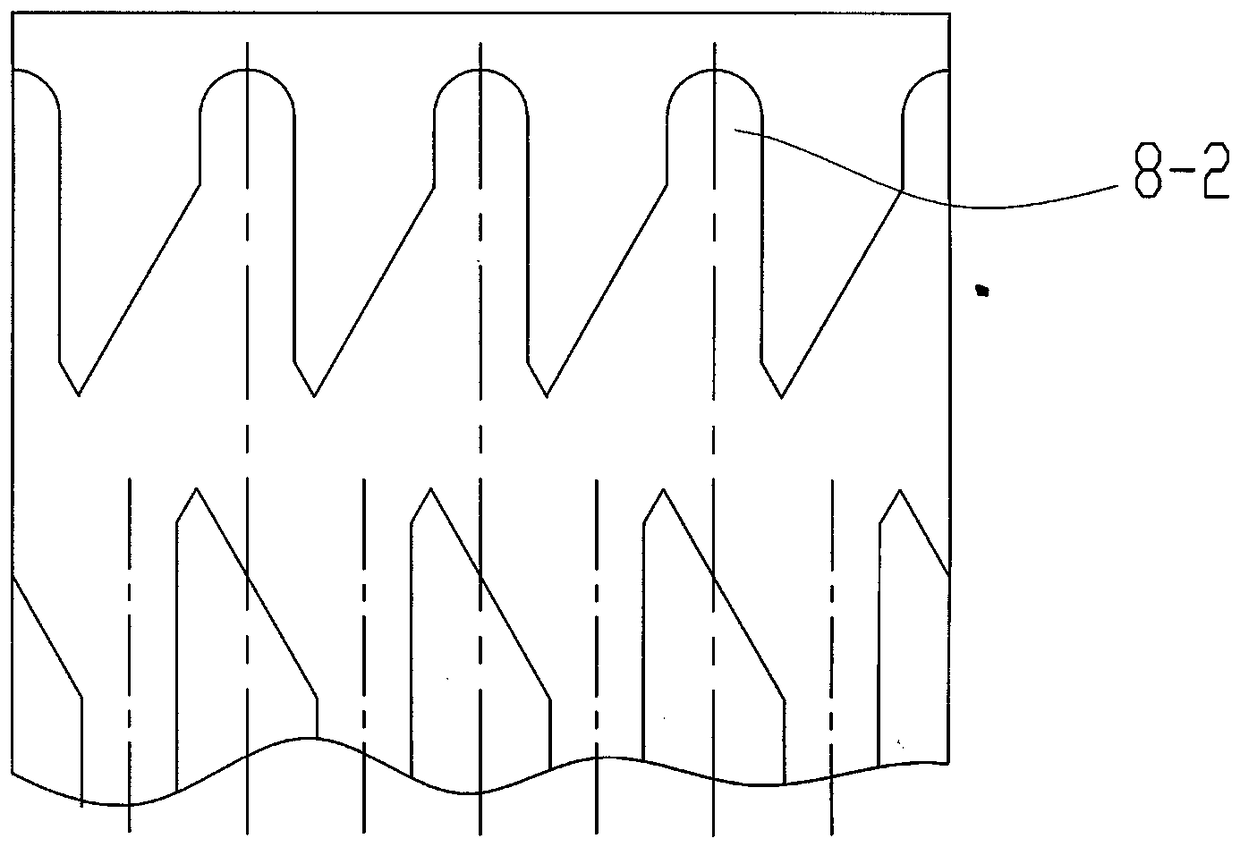

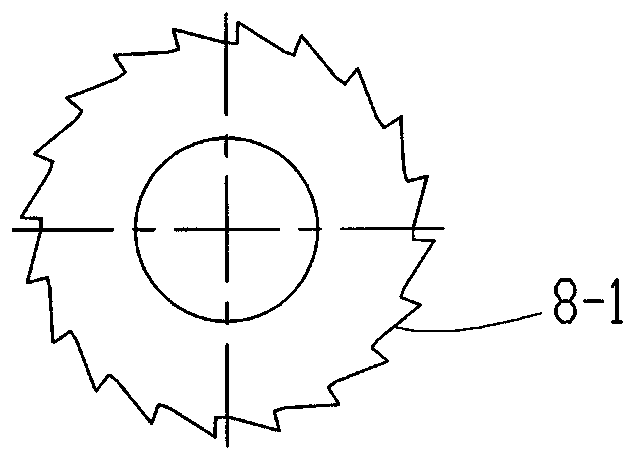

[0010] attached by figure 1 It can be seen that the embodiment of the present invention includes a polished rod 1, a clip 2, a spring seat 3, a pin sleeve 4, a pin 5, a spring 7, a track tube 8, a retaining sleeve 9, an anti-back spring 10, an adjustment cap 11, a pin tube 12, and a ratchet Pin 13, rotary sleeve 14, polished rod sealer 15, the bottom of track pipe 8 has ratchet tooth 8-1 (as image 3 Shown), there is a track 8-2 on the track tube 8 (as figure 2 As shown), the orbital tube 8 is placed in the upper part of the rotary sleeve 14, the lower part of the orbital tube 8 is connected with the polished rod sealer 15, and the pin tube 12 is installed horizontally on the side wall of the rotary sleeve 14, and the pin tube 12 corresponds to the above-mentioned ratchet Tooth 8-1, ratchet pin 13, anti-back spring 10 are installed in the pin tube 12, the front end of ratchet pin 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com