Liquid cooling system, and quick connector female connector

A female joint, fast technology, applied in the direction of functional valve type, lighting and heating equipment, heat exchanger sealing device, etc., can solve the problem of cooling module damage, system supply pressure instability, and the pressure in the liquid cooling module cannot be completely removed and other issues to achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

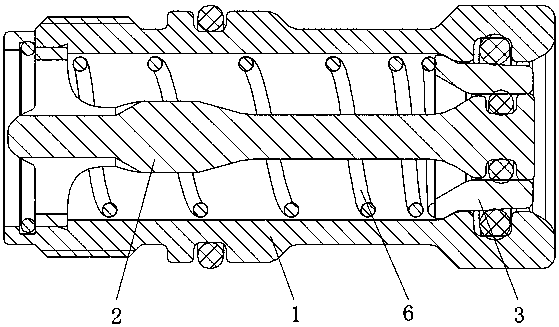

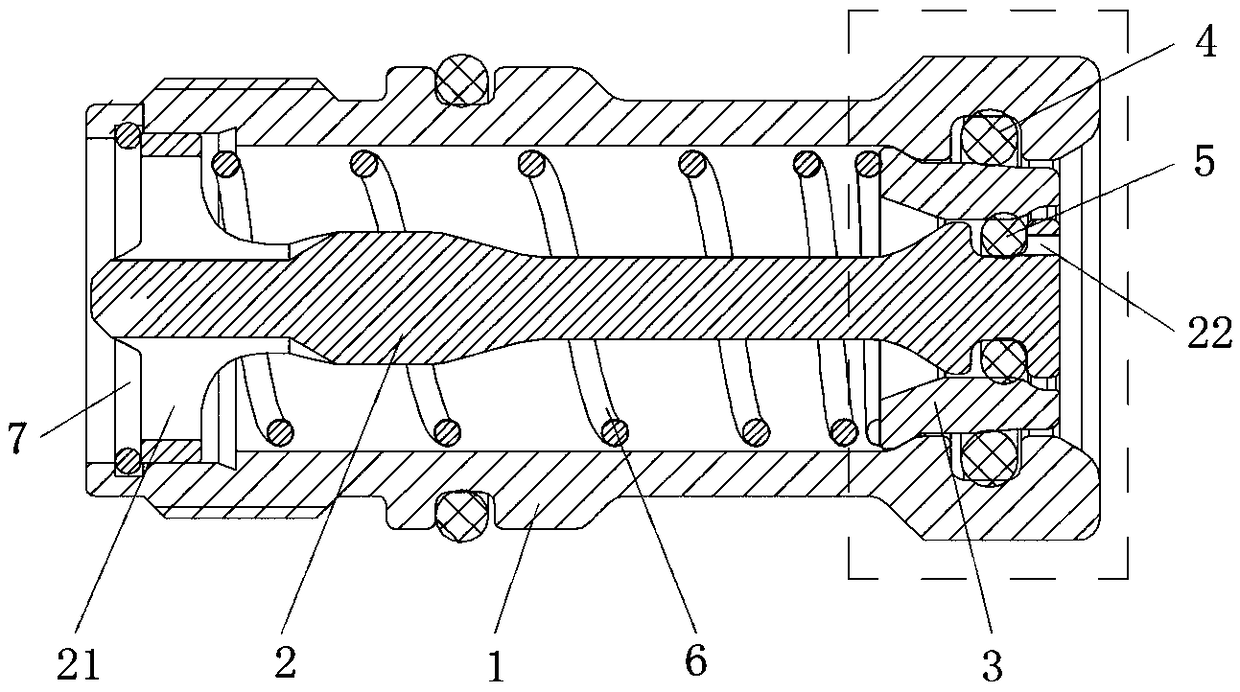

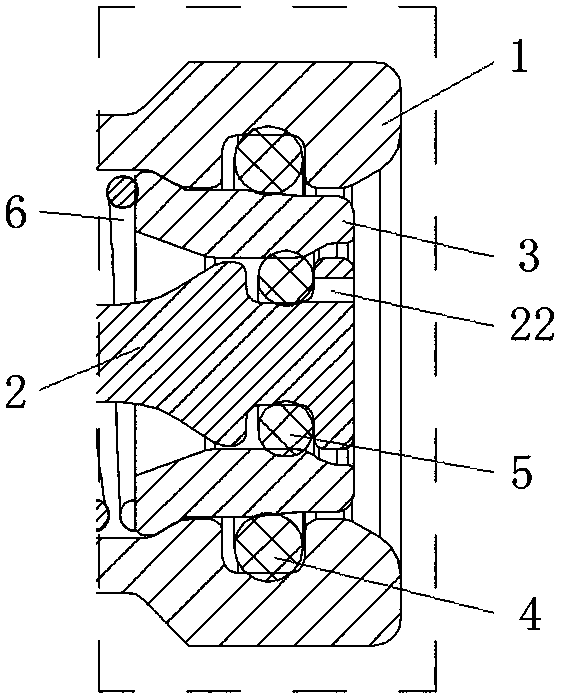

[0020] A specific embodiment 1 of a liquid cooling system of the present invention includes a cooling module, and the cooling module is provided with a quick connector female connector, and the specific structure of the quick connector female connector is as follows figure 2 As shown, it includes a cylindrical shell 1. The inner side of the cylindrical shell 1 is in the shape of a three-stage stepped hole. The diameter of the stepped hole gradually increases from the insertion end to the rear, and a front end step is formed between the small diameter section at the front end and the stepped section at the middle. The stepped surface is an inclined surface, and the rear-end stepped surface is formed between the middle stepped section and the rear-end large-diameter section.

[0021] The cylindrical housing 1 is provided with a sealing rod 2 along the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com