Projector hoisting mechanism convenient to install and remove for electrified education equipment

A technology that is convenient for installation and instrument hoisting. It is applied in the direction of mechanical equipment, supporting machines, machine tables/supports, etc. It can solve the problems of inconvenient installation and disassembly of projectors, slow bolt screwing speed, etc., and achieves convenient maintenance, quick installation and disassembly, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

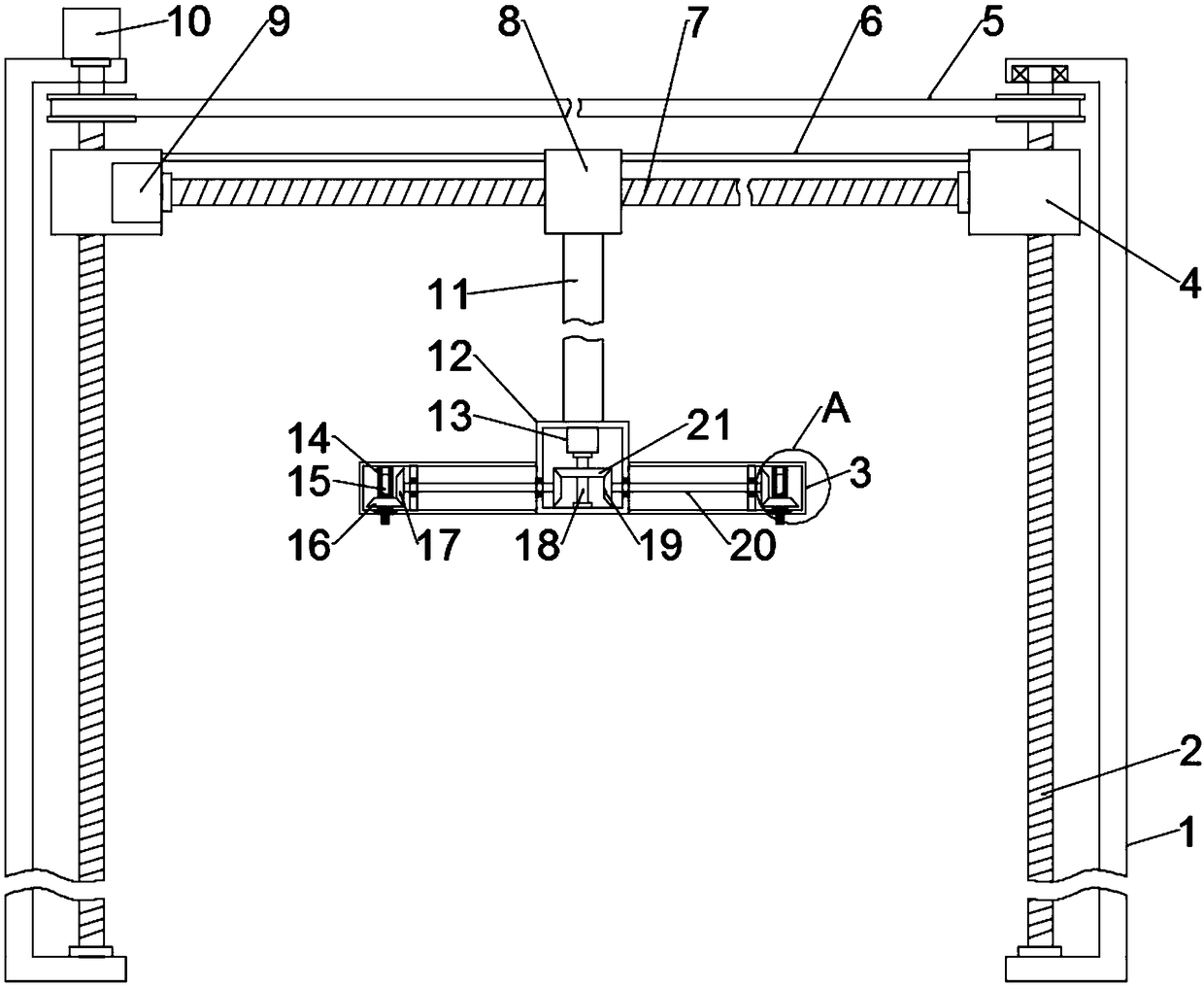

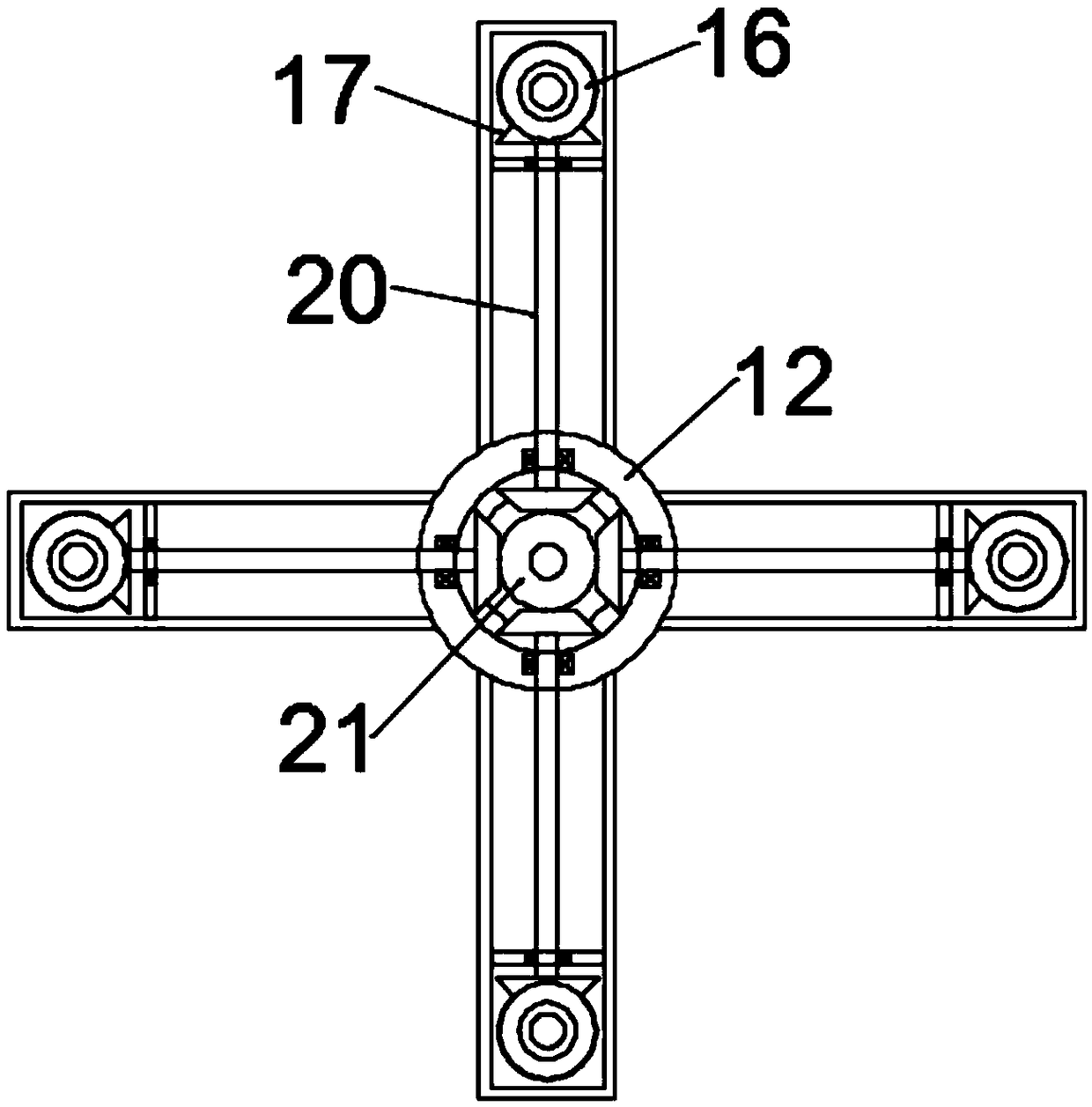

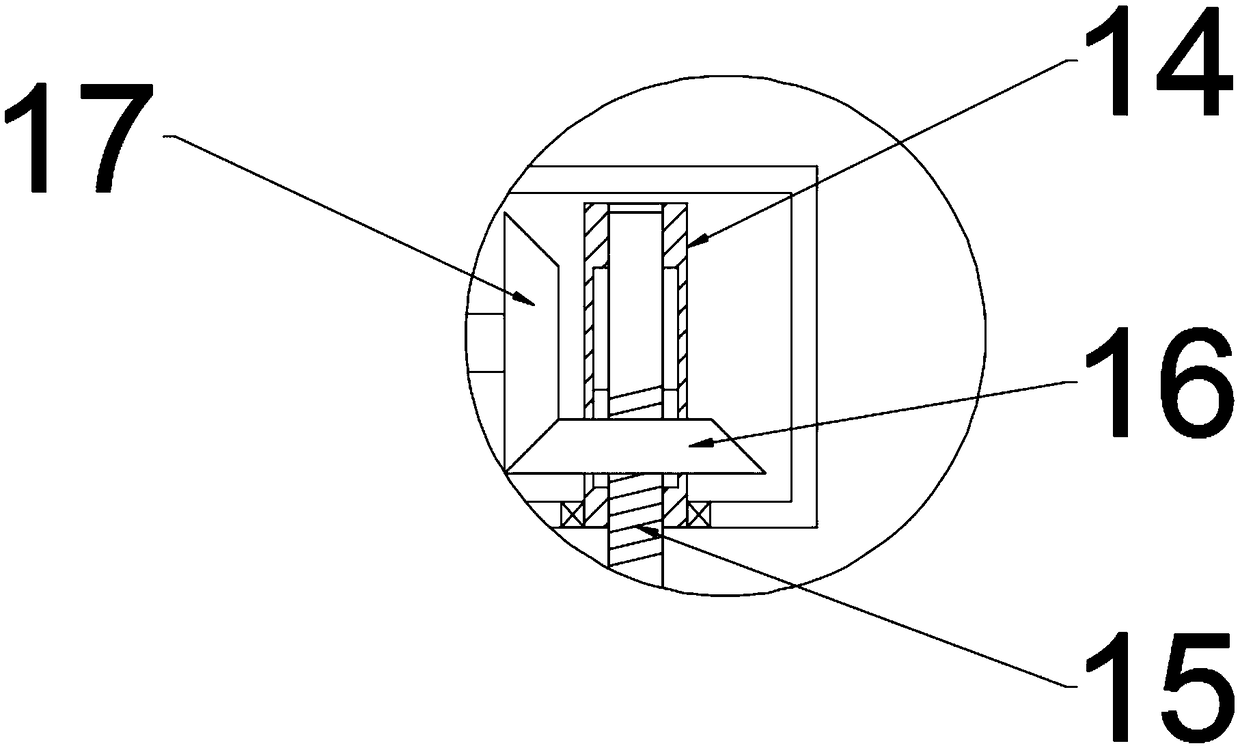

[0024] see Figure 1~3 , in an embodiment of the present invention, a projector hoisting mechanism for an audio-visual equipment that is convenient for installation and disassembly includes a hoisting seat 8, a hoisting column 11, a mounting shell 12, and a hoisting claw 3, and the bottom of the hoisting seat 8 is welded with a hoisting column 11 , the bottom end of the hoisting column 11 is connected with an installation shell 12 by screws, and four hoisting claws 3 are mounted equidistantly around the installation shell 12 by screws. There is an internally threaded hole threaded with the first threaded rod 7, the two ends of the first threaded rod 7 are rotatably connected to the movable seat 4 through bearings, and the first threaded rod 7 is fixed to the output shaft of the first motor 9 through a coupling Connection, the first motor 9 is installed in the movable seat 4 by screws, the upper part of the lifting seat 8 is pierced with a guide rod 6, and the lifting seat 8 is...

Embodiment 2

[0026] see Figure 4, The difference between this embodiment and Embodiment 1 is that it also includes a steering device, the steering device includes a stepping motor 23, a gear 24 and an outer ring gear 25, and the lifting column 11 is installed through a bearing seat and a bearing The shell 12 is rotatably connected, the two sides of the hoisting column 11 are welded and fixed with a support rod 22, the bottom end of the support rod 22 is slidingly connected with the top of the installation shell 12 through a T-shaped slider, and the top of the installation shell 12 is provided with an annular The chute, the stepper motor 23 is installed on the hoisting column 11 through the mounting plate, the output shaft end of the stepper motor 23 is equipped with a gear 24, the gear 24 meshes with the outer ring gear 25 on the installation shell 12, and the outer ring gear The connection mode between 25 and the installation shell 12 is preferably welding, and the stepper motor 23 drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com