Straight-plugged LED decorative lamp structure and manufacturing process thereof

A technology of LED decorative lights and manufacturing process, which is applied to lighting devices, lighting device components, light sources, etc., can solve the problems of time-consuming and labor-consuming, poor stability of bonding chips, and increased risk of failure, so as to increase the light-splitting effect , Reduce the trouble of assembly and reduce the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

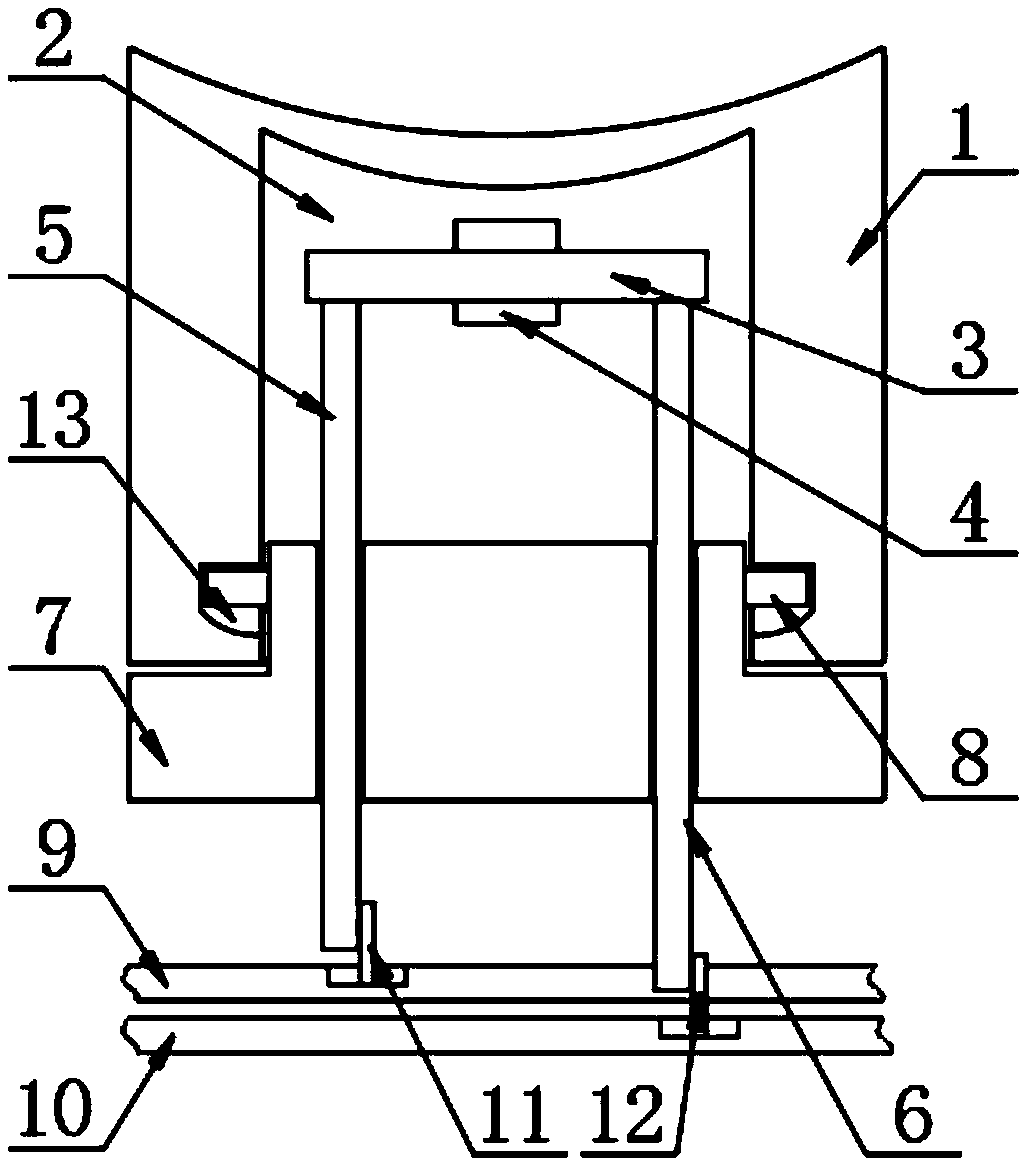

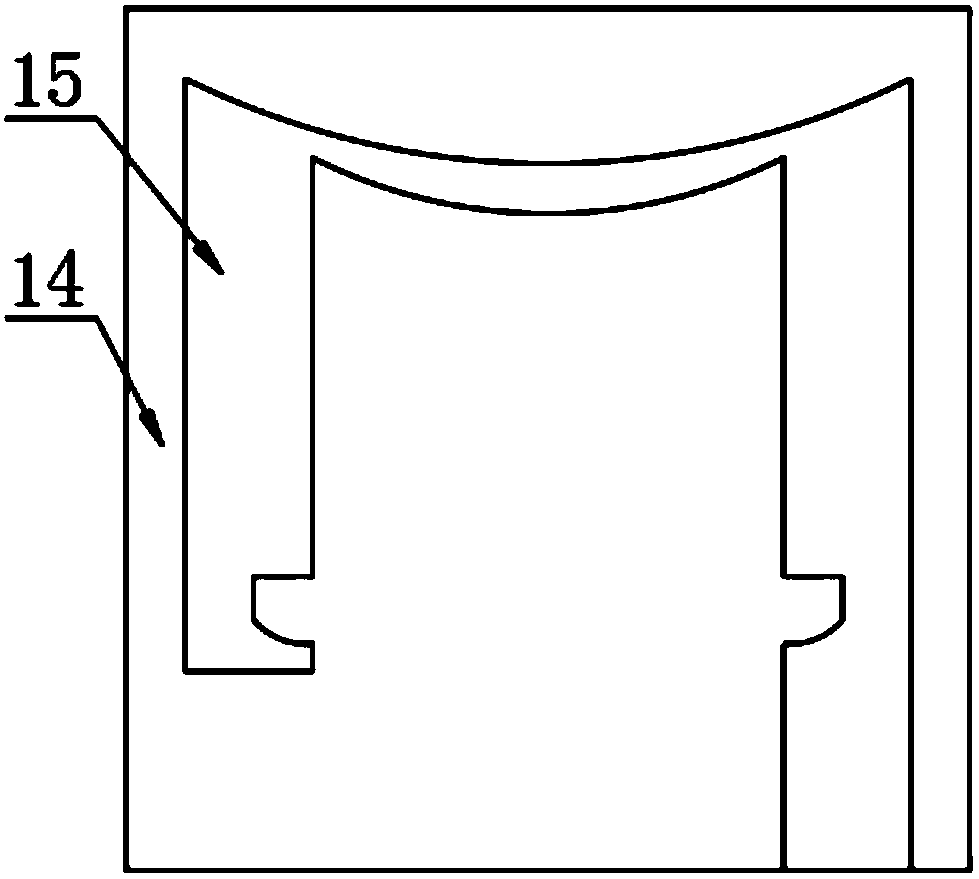

[0023] The present invention provides such Figure 1-2 An in-line LED decorative lamp structure is shown, which includes a housing 1 and a mold 14. The housing 1 is provided with a storage compartment 2 inside. The storage compartment 2 is provided with a light-emitting board 3 inside. Lamp holder 4, a first pin 5 is provided at the bottom of the light-emitting board 3, a second pin 6 is provided on one side of the first pin 5, a patch 7 is provided at the bottom of the shell 1, and the patch 7 A protruding ring 8 is provided on the outside, a first connection line 9 is provided at the bottom of the patch 7, a second connection line 10 is provided at the bottom of the first connection line 9, and a first connection line is provided on the surface of the first connection line 9. 11. The surface of the second connecting wire 10 is provided with a second wire 12 , the surface of the inner wall of the housing 1 is provided with an inner groove 13 , and the inner side of the mold 1...

Embodiment 2

[0027] The present invention also provides a manufacturing process for an in-line LED decorative lamp, comprising the following steps:

[0028] Step 1, material selection: select 2 parts of the first pin 5, 2 parts of the second pin 6, 1 part of the light-emitting board 3, 1 part of the lamp holder 4, 2 parts of the patch 7, 1 part of glue, and 4 parts of polycarbonate and 3 parts of transparent silica gel, the first pin 5 and the second pin 6 can be made of copper bracket material or chrome-plated iron bracket material, and the length of the second pin 6 is greater than the length of the first pin 5;

[0029] Step 2, preparation of shell 1: choose sand to make two molds 14 of the same size, and then carve the same mold cavity 15 inside the mold 14, place the two molds 14 correspondingly, melt the polycarbonate, and then pass through the mold 14 Pour in the gap at the bottom, and after cooling for a period of time, spread the sand to obtain Shell 1. The polycarbonate is heated...

Embodiment 3

[0033] The present invention also provides a manufacturing process for an in-line LED decorative lamp, comprising the following steps:

[0034] Step 1, material selection: select 4 parts of the first pin 5, 4 parts of the second pin 6, 3 parts of the light-emitting board 3, 3 parts of the lamp holder 4, 4 parts of the patch 7, 5 parts of glue, and 8 parts of polycarbonate and 7 parts of transparent silica gel, the first pin 5 and the second pin 6 can be made of copper bracket material or chrome-plated iron bracket material, and the length of the second pin 6 is greater than the length of the first pin 5;

[0035] Step 2, preparation of shell 1: choose sand to make two molds 14 of the same size, and then carve the same mold cavity 15 inside the mold 14, place the two molds 14 correspondingly, melt the polycarbonate, and then pass through the mold 14 Pour in the bottom gap, and after cooling for a period of time, spread the sand to obtain shell 1. The polycarbonate is heated and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com