Air outlet device and control method and air conditioner

A technology of air outlet device and air conditioner, which is applied in the direction of airflow control components, heating methods, high-efficiency adjustment technology, etc. It can solve the problems of high wind speed and small dispersion of wind field, and achieve stable temperature control, easy conversion, and precise adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

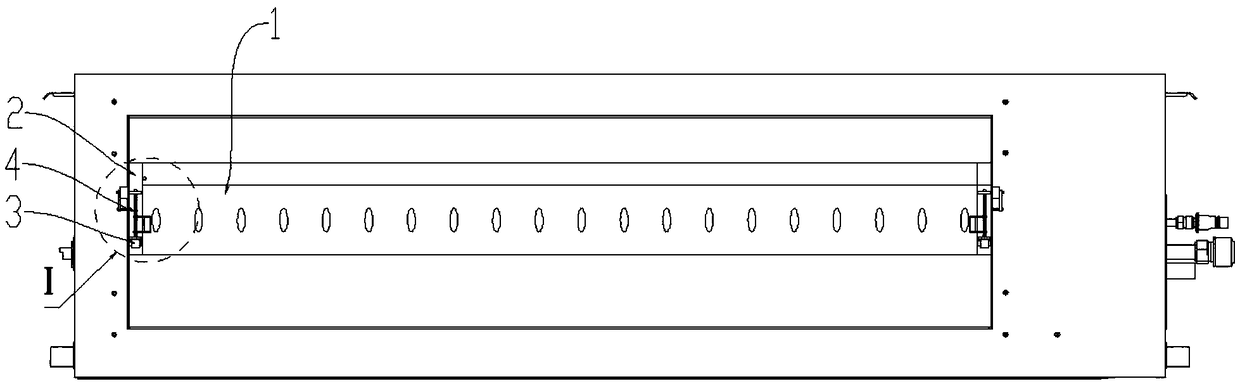

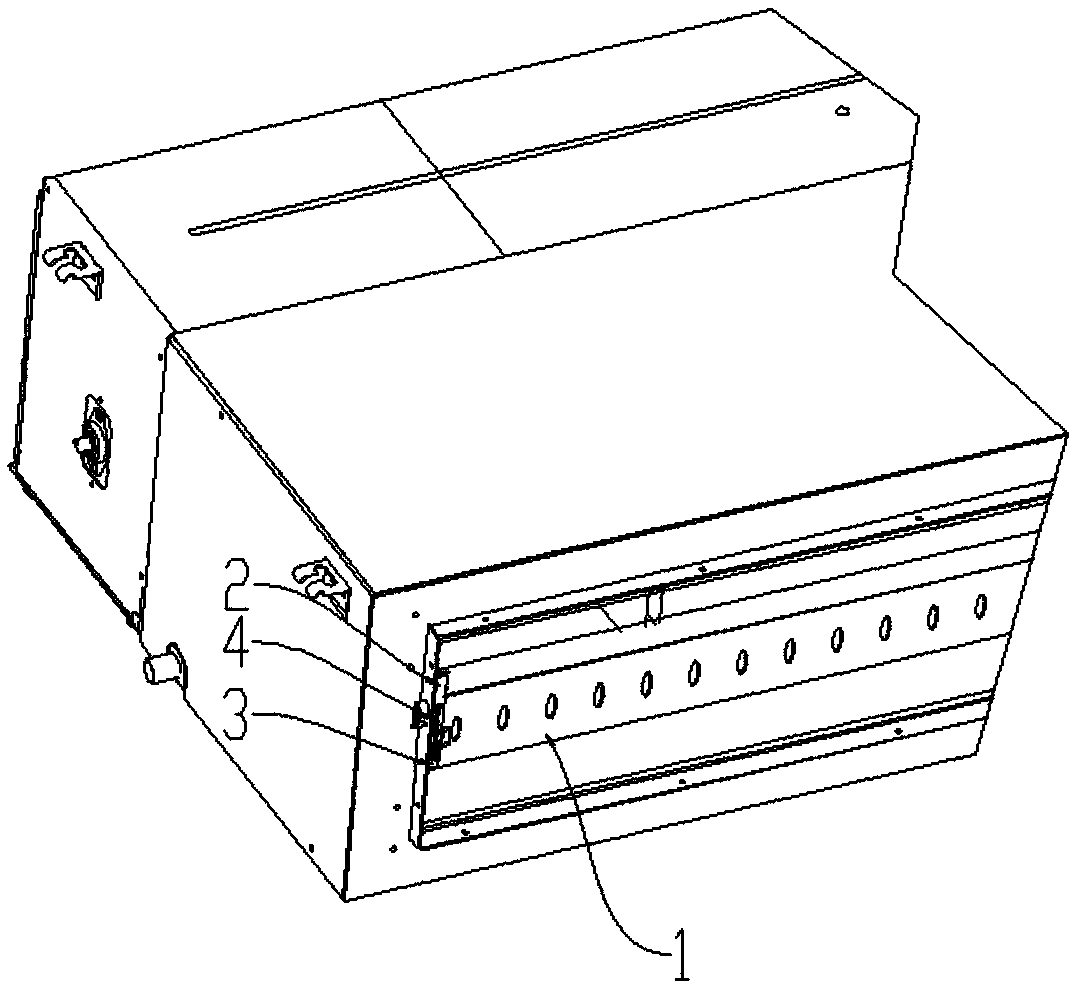

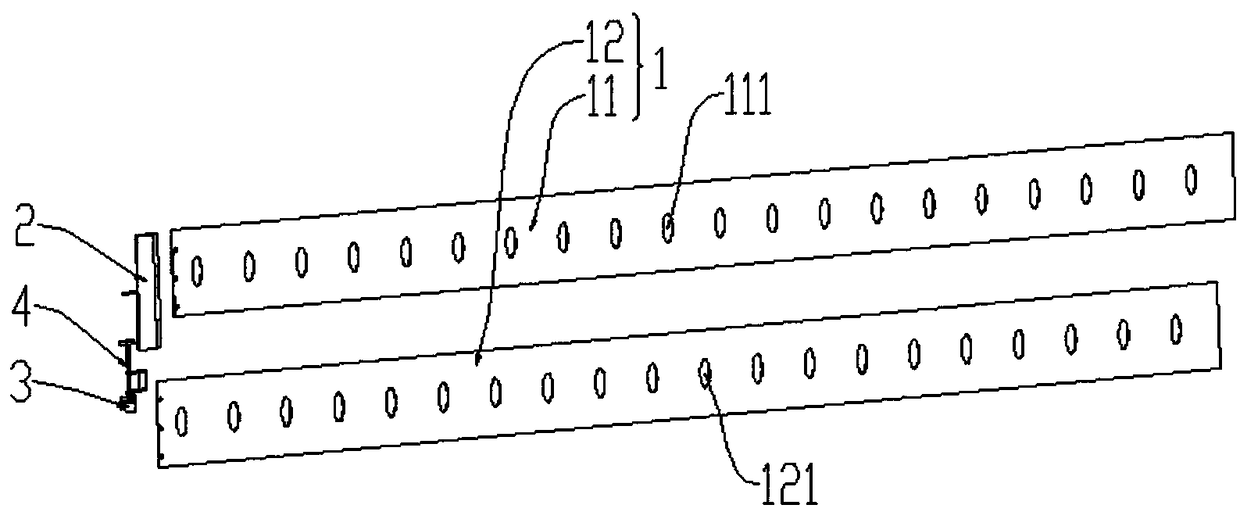

[0044] This embodiment provides an air outlet device, combined with Figure 1-Figure 4 As shown, the air outlet device includes a wind guide vane 1, a bracket 2, a first stepping motor 3 and a transmission device 4, the wind guide vane 1 is installed at the air outlet of the air conditioner, the wind guide vane 1 is a double-layer structure, and the wind guide The vane 1 is made of metal or injection molding material. Specifically, the wind guide vane 1 includes a first vane 11 and a second vane 12. The first vane 11 and the second vane 12 are both strip-shaped, and the first vane 11 and the second vane 12 are The second blade 12 is overlapped, that is, a plate surface of the first blade 11 is in contact with a plate surface of the second blade 12, and the first blade 11 is fixed on the bracket 2. Preferably, the two ends of the first blade 11 The brackets 2 are fixedly connected respectively.

[0045] The brackets 2 at both ends are provided with a first stepping motor 3 and...

Embodiment 2

[0052] On the basis of the above-mentioned embodiments, this embodiment combines Figure 6 As shown, the first through hole 111 and the second through hole 121 are both waist-shaped holes or elliptical holes, which can better control the size of the dislocation hole, and the first through hole 111 and the second through hole 121 have the same size The position where the first through hole 111 is located on the first blade 11 corresponds to the position where the second through hole 121 is located on the second blade 12, and the width D1 of the first through hole 111 and the second through hole 121 is in the range of 4-10 mm, It is preferably 6 mm, and the width D1 is the shortest inner diameter of the waist or the semi-minor diameter of the elliptical hole. In this embodiment, the width direction of the first through hole 111 is the same as the length direction of the first blade 11, and the second through hole 111 is the same as the length direction of the first blade 11. The...

Embodiment 3

[0056] On the basis of the above-mentioned embodiments, this embodiment combines Figure 4 As shown, the left end of support 2 is also provided with a second stepper motor 5, the axis of the rotating head of the second stepper motor 5 is parallel to the length direction of the wind guide vane 1, and the second stepper motor 5 is used to drive the wind guide vane 1 Make a swing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com