Combustion chamber

A combustion chamber and air duct technology, applied in the field of combustion chamber, can solve the problems of long combustion flame, low combustion efficiency, large combustion chamber volume, etc., and achieve the effects of improving the utilization rate of heat energy, prolonging the working life, and improving the degree of atomization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

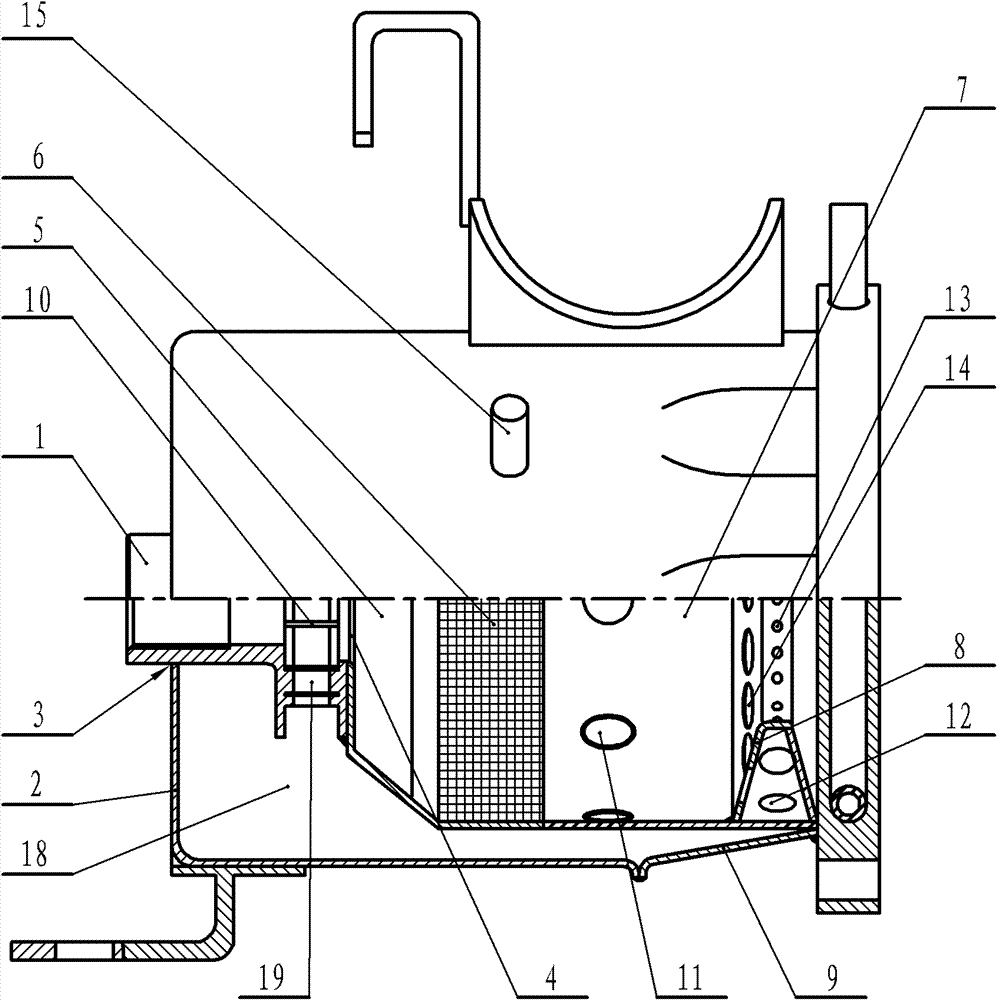

[0029] Combustion chamber of the present invention, structure such as attached figure 1As shown, it includes fuel injector seat 1, combustion chamber casing 2, front air cylinder 5, rear air cylinder 7, butterfly wind plate 8 and plum blossom cylinder 9, the connection between combustion chamber casing 2 and front air cylinder 5 and rear air cylinder 7 An air channel 18 completely surrounding the front air cylinder 5 and the rear air cylinder 7 is arranged between them, and the shell of the fuel injector seat 1 is fixedly connected with the front center hole 3 of the combustion chamber shell 2 and the central oil inlet hole 4 of the front air cylinder 5 respectively. The axis of the fuel injector seat 1 coincides with the axis of the front air cylinder 5, the fuel injection port of the fuel injector seat 1 is flush with the inner wall of the front end of the front air cylinder 5, and the fuel injector seat 1 is located outside the outer wall of the front air cylinder 5 An air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com