Slicer

A slicer and cutting mechanism technology, applied in the field of cable equipment, can solve the problems of manpower consumption, expensive equipment cost, and high labor cost, and achieve the effects of low cost, reduced labor cost, and improved slicing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following is further described in detail through specific implementation methods:

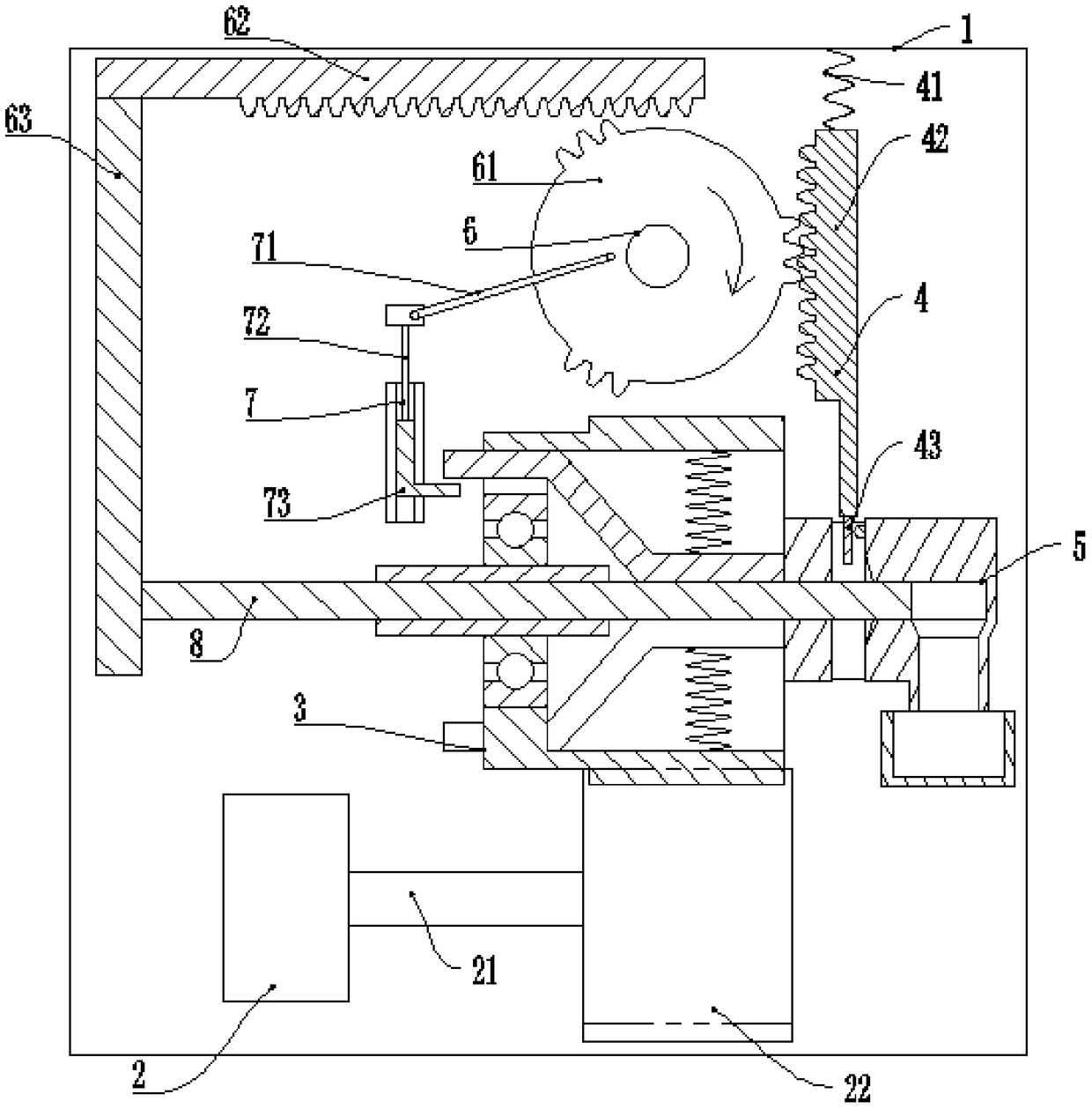

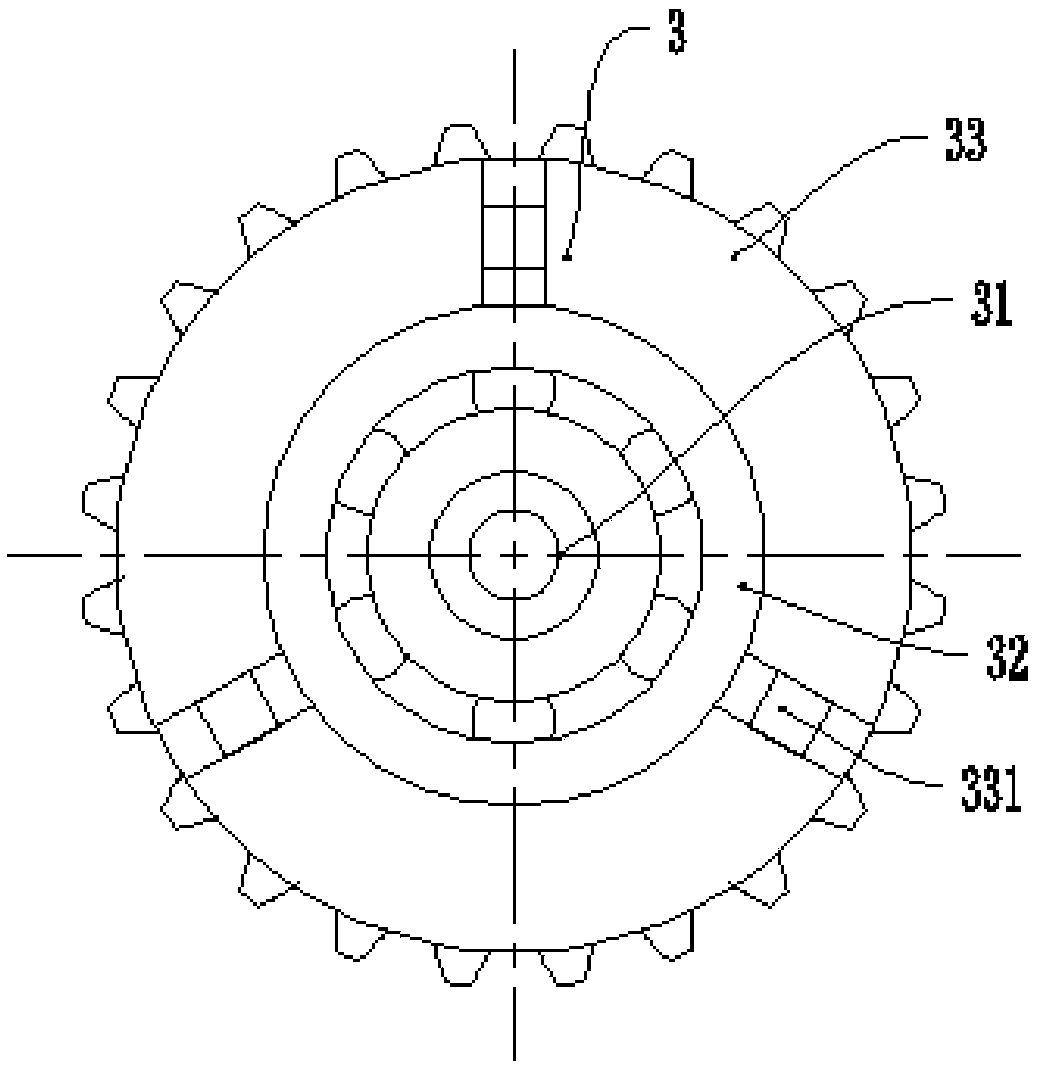

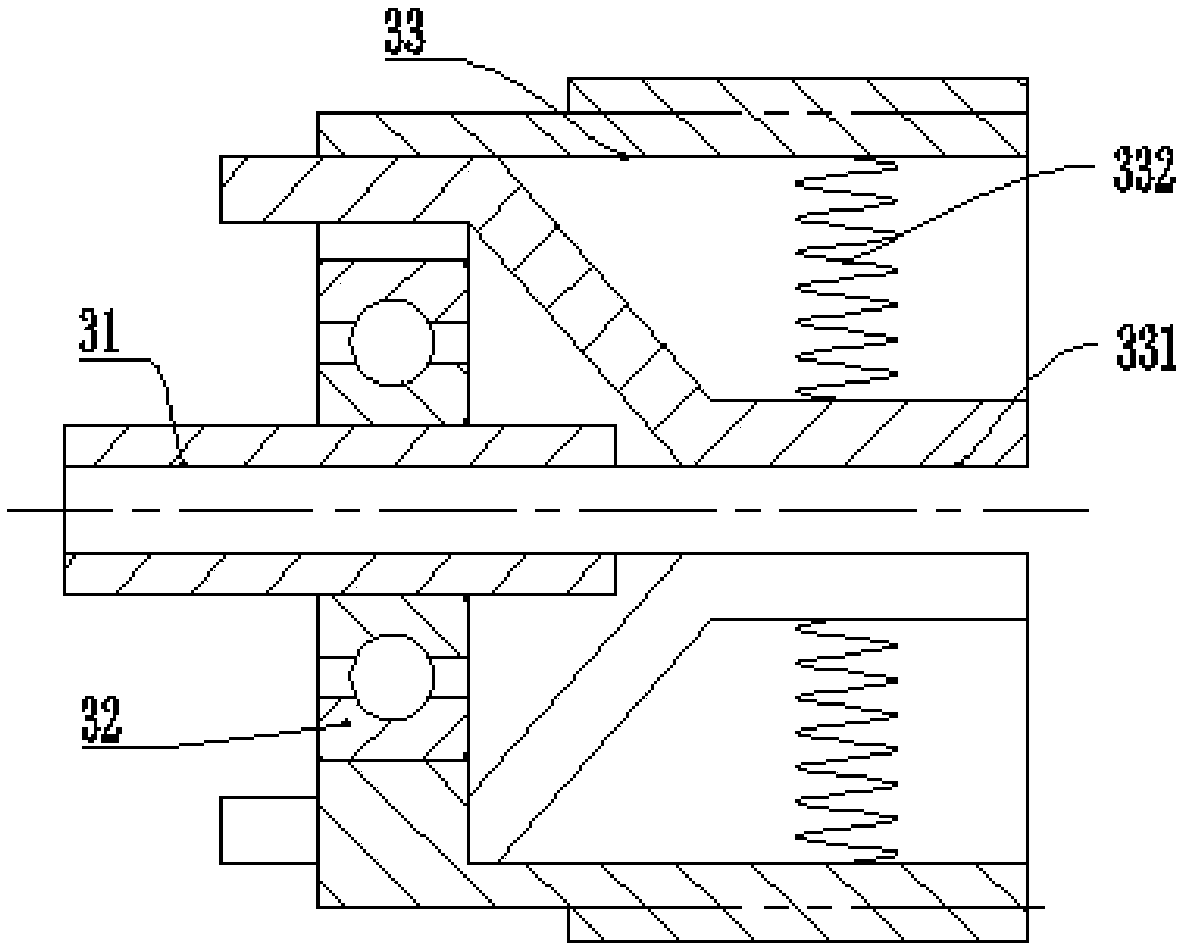

[0033]The reference signs in the accompanying drawings are: frame 1, servo motor 2, clamping mechanism 3, cutting mechanism 4, blanking seat 5, feeding mechanism 6, crank slider mechanism 7, cable 8, output shaft 21, gear 22 , hollow shaft 31, ball bearing 32, clamping plate 33, clamping block 331, first spring 332, second spring 41, knife holder 42, circular slicer 43, blanking seat body 51, button switch 52, collection Frame 53, feeding hole 511, cutting hole 512, incomplete gear 61, transverse rack 62, push plate 63, crank 71, connecting rod 72 and slide block 73, the direction indicated by arrow is the rotational direction of incomplete gear among the figure.

[0034] Figure 1 to Figure 4 Shown is an embodiment of the microtome of the present invention.

[0035] Such as figure 1 As shown, the slicer includes a frame 1, a servo motor 2, a clamping mechanism 3, a cutting mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com