Novel all-purpose tensile machine clamp and application

A tensile machine, a versatile technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problem of inability to clamp the bracket pins, achieve simple structure, enhance reliability, and reduce testing. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

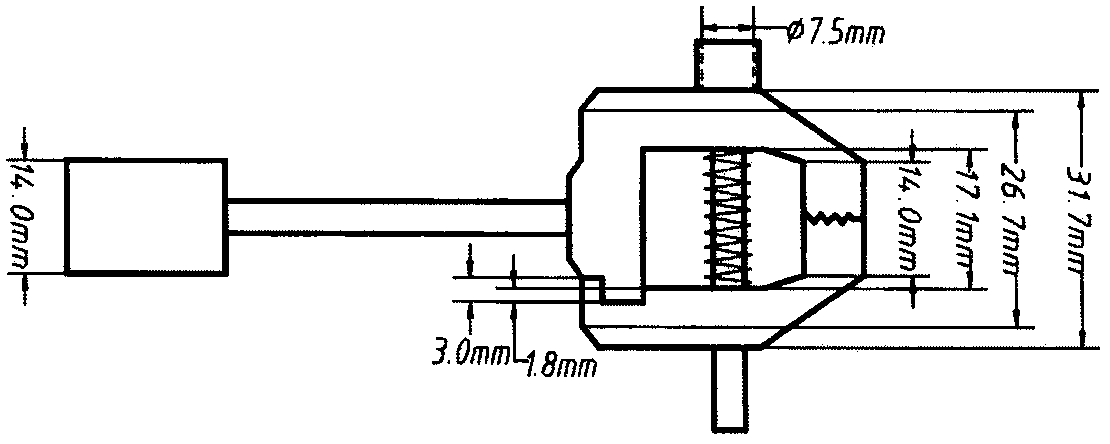

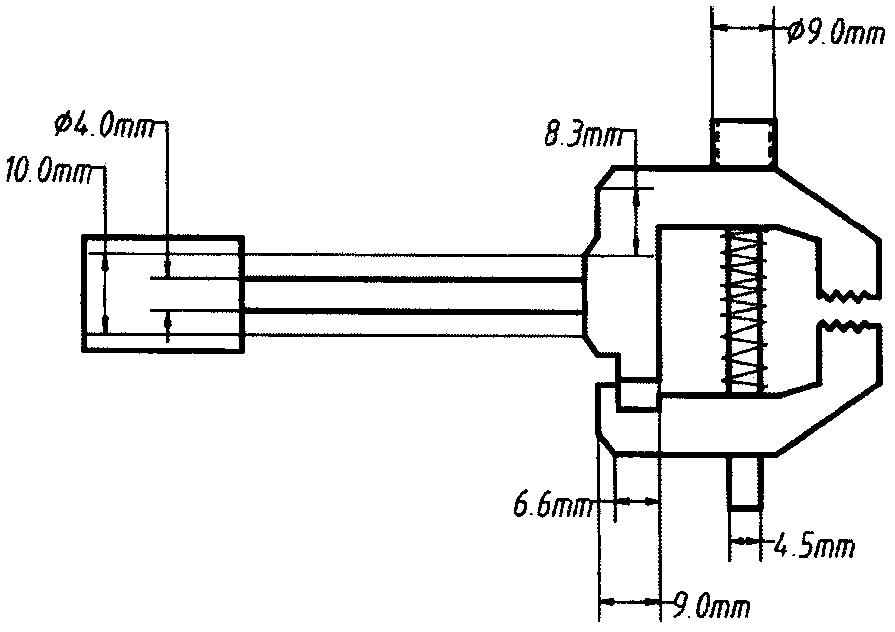

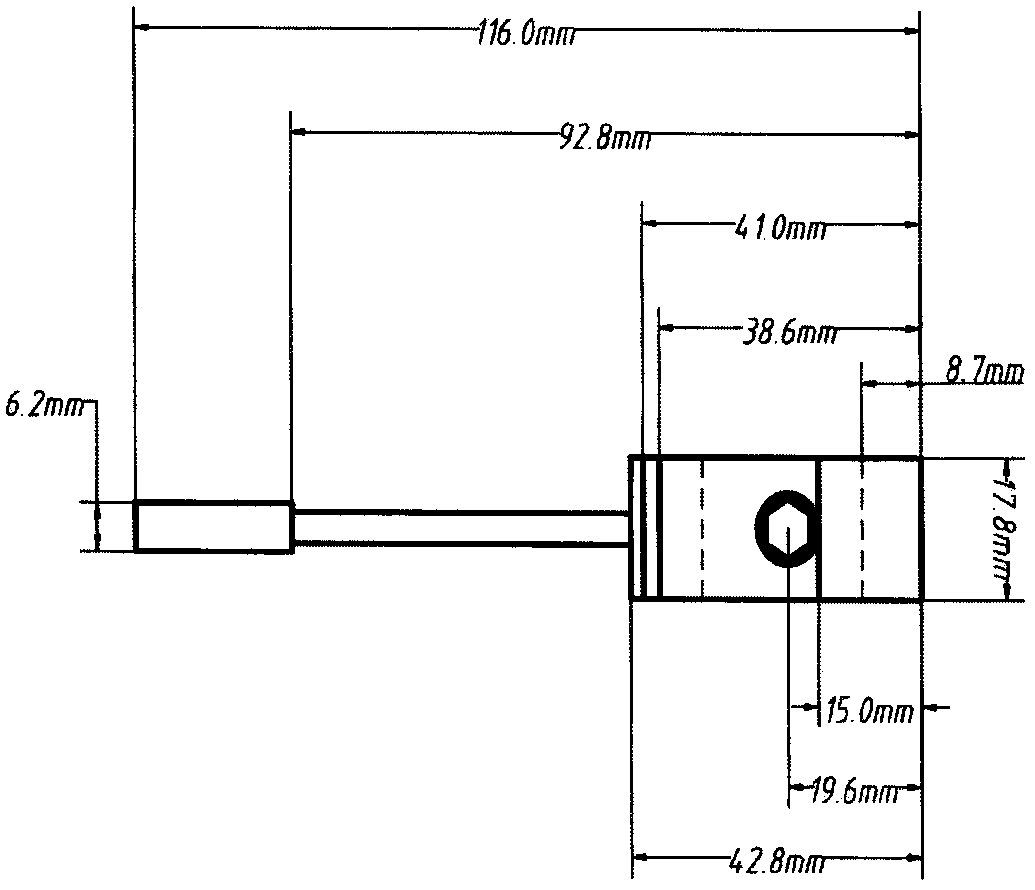

[0012] Embodiment 1 A new type of clamp for a universal tensile machine according to the present invention includes three parts: an iron clip, an alloy force transmission bracket, and an alloy chuck. The three parts are fixed by electric welding. For specific dimensions, see Figure 1-Figure 3 .

[0013] The clip is an iron sheet with a length of 23.2mm, a width of 14.0mm, and a thickness of 6.2mm, which is fixed by the chuck of the universal tensile machine;

[0014] The alloy force transmission bracket is a cylindrical alloy bracket with a length of 50.0mm and a diameter of 4.0mm, which is used to conduct the tension between the iron clip and the alloy chuck;

[0015] The alloy collet includes a fixed collet and a movable collet, and the fixed collet and the movable collet are connected by a hexagon socket bolt with a diameter of 9.0 mm. A spring is convenient for the use of the fixture; the jaws are serrated to increase the clamping force of the jaws and improve the stabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com