Multi-core cable terminal pressing method and multi-core cable terminal pressing machine by employing same

A technology of terminal crimping machine and multi-core wire, which is applied to circuit/collector parts, electrical components, circuits, etc., can solve the problems of high product defect rate, increase the burden on enterprises, and cannot use multi-core wire, etc., and achieve convenient control. , the effect of improving production efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

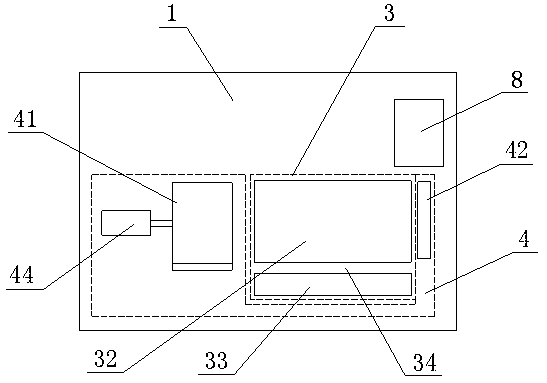

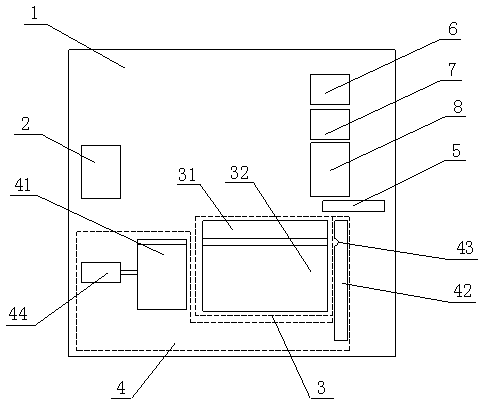

[0042] This embodiment proposes a multi-core wire crimping terminal method with a high degree of automation and a multi-core wire crimping machine applying this method to replace the traditional manual operation method, thereby improving production efficiency, ensuring product quality, and reducing production costs. .

[0043] The multi-core wire crimp terminal method in this embodiment includes the following steps:

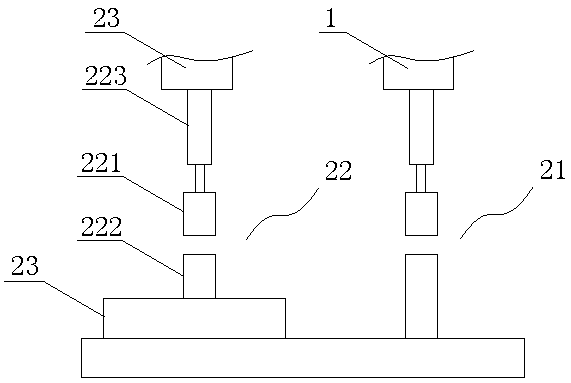

[0044] A: Strip the end of the multi-core wire to expose the wires of the multi-core wire, use the first clamp to clamp the unstripped part of the multi-core wire, and use the second clamp to clamp the exposed wire of the multi-core wire. The clamping force of the clamp is less than the clamping force of the first clamp, and then the second clamp is moved to the end of the wire, so that the exposed wire is clamped into a row by the second clamp to form a wire row; in this embodiment, the second clamp The first clamp is the multi-core wire clamping device in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com