Gas desulfurization method and apparatus

A treatment device and gas injection device technology, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of changing desulfurization agent, interrupting combustion power generation operation, affecting power generation efficiency, etc., so as to increase the contact area, Evenly distributed, the effect of improving the efficiency of sulfur removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

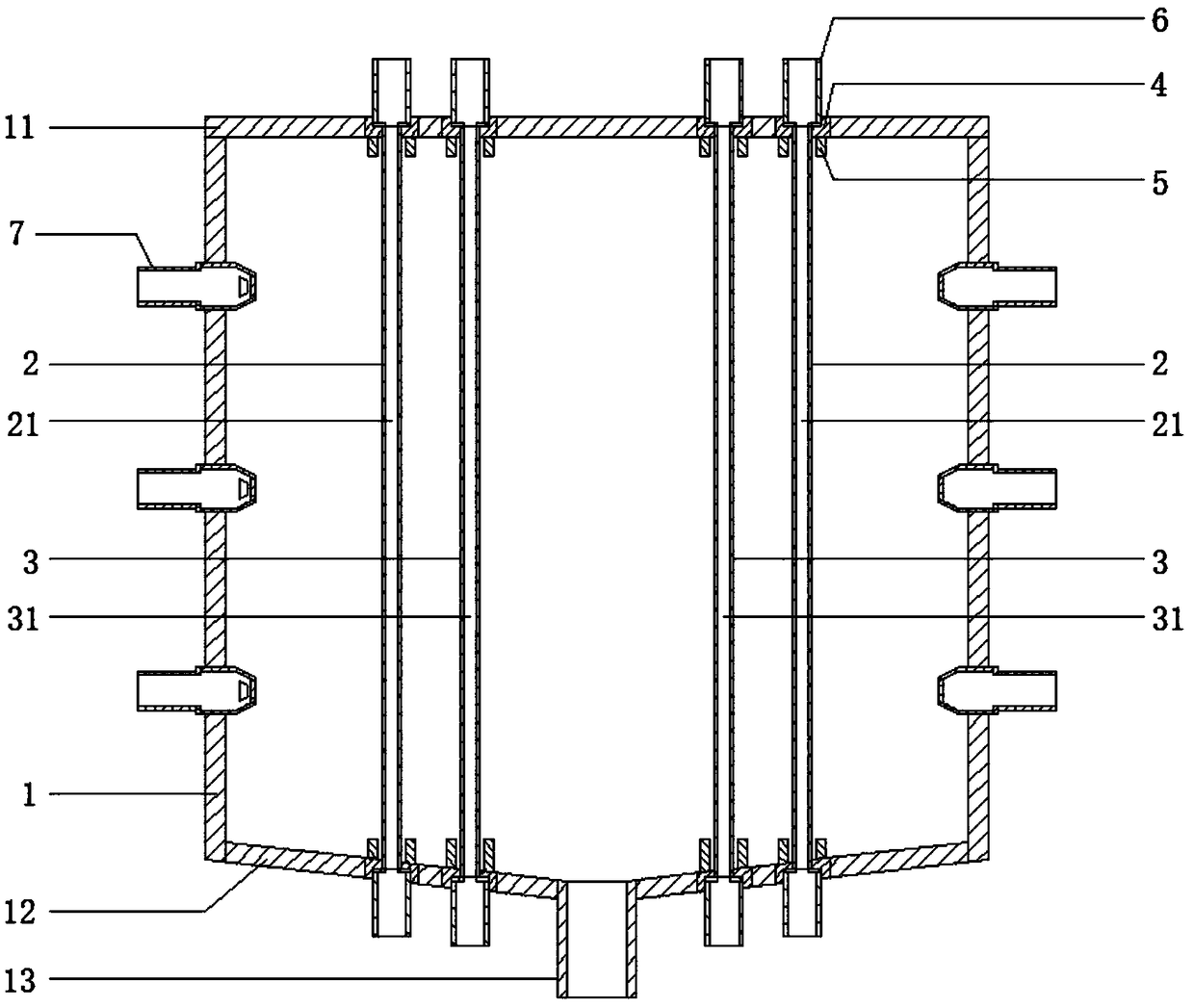

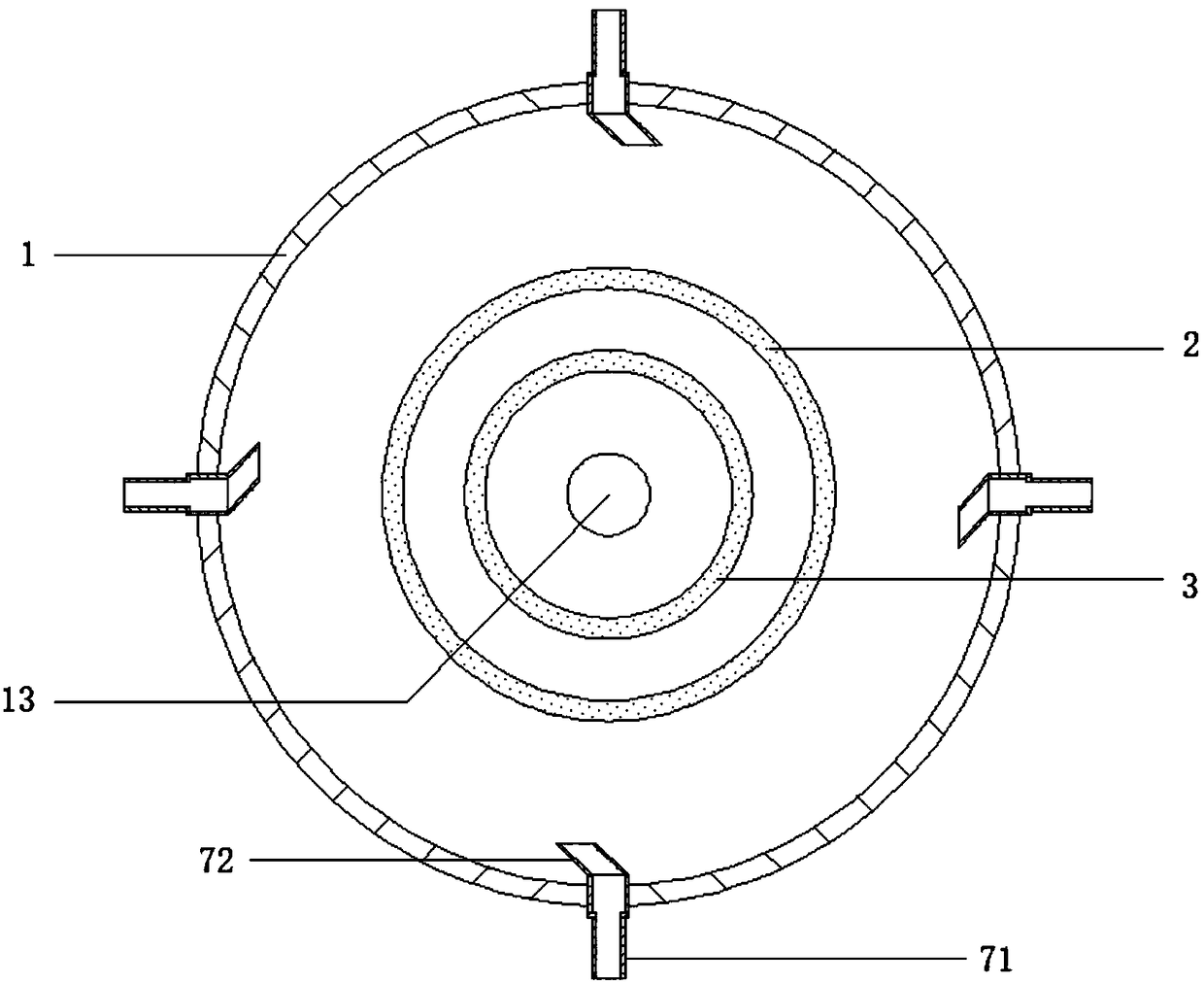

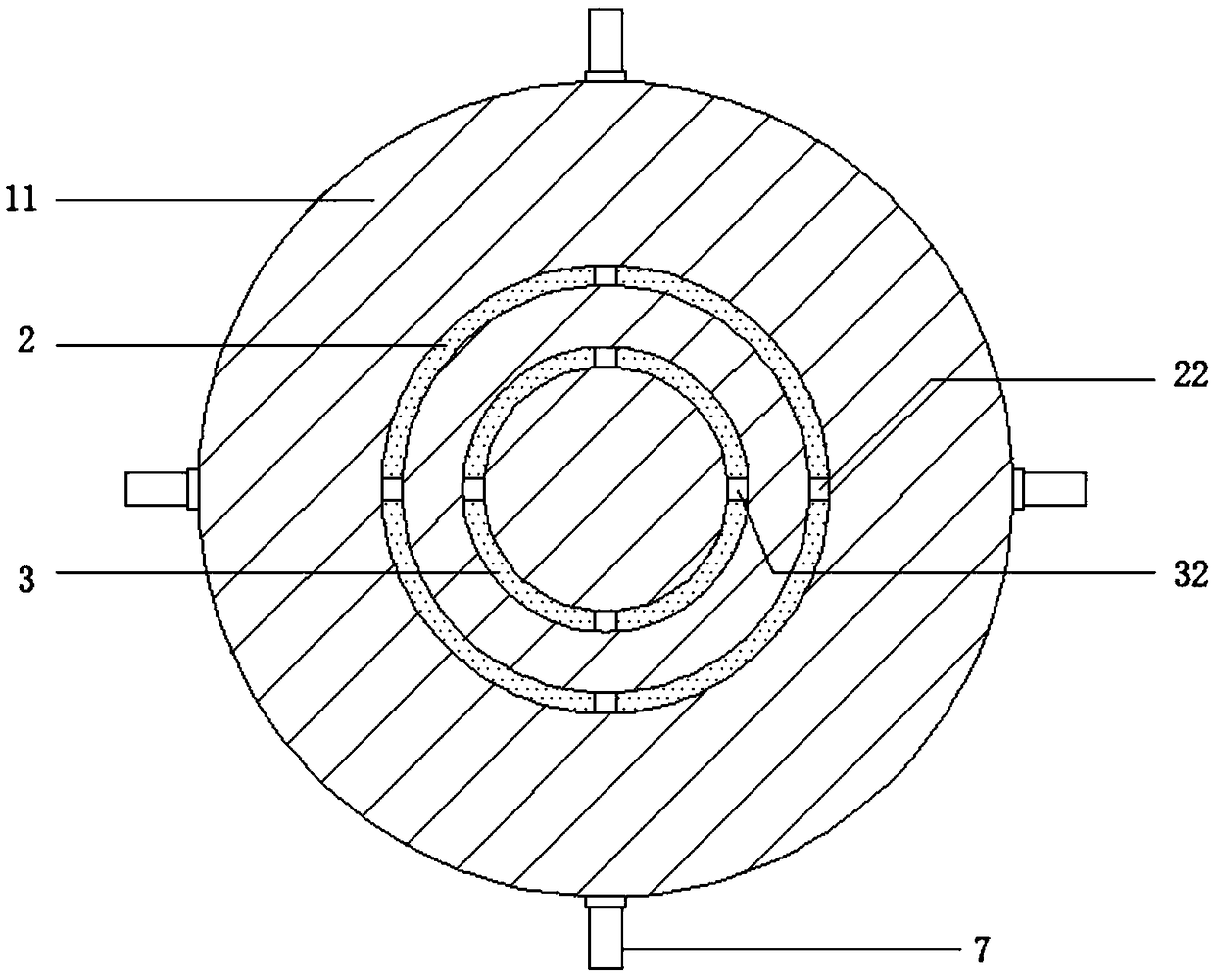

[0026] as attached Figure 1-4 As shown, the present invention includes a housing 1, a top plate 11 arranged at the top of the housing 1 and a bottom plate 12 arranged at the bottom of the housing 1, including an air injection device arranged on the housing 1 and a filtering device arranged inside the housing 1 The air injection device includes at least two air injection pipes 7, and the air injection pipe 7 includes an air injection pipe 71 and an air injection head 72 for changing the direction of the air flow, and the air flow ejected by the two air injection heads 72 is in the same direction in the housing 1 Circular movement; the filter device includes a filter cartridge I2 and a filter cartridge II3 fixed between the top plate 11 and the bottom plate 12, the filter cartridge I2 is set outside the filter cartridge II3, and the bottom plate 12 surrounded by the filter cartridge II3 is provided with a useful In the outlet pipe 13 leading out the desulfurized gas, the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com