A high-efficiency desulfurization tower

A desulfurization tower, high-efficiency technology, applied in the field of environmental protection facilities, can solve the problems of incomplete sulfur removal, low efficiency, and impact, and achieve the effect of ensuring the effect of sulfur removal, ensuring the effect of sulfur removal, and improving the efficiency of sulfur removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

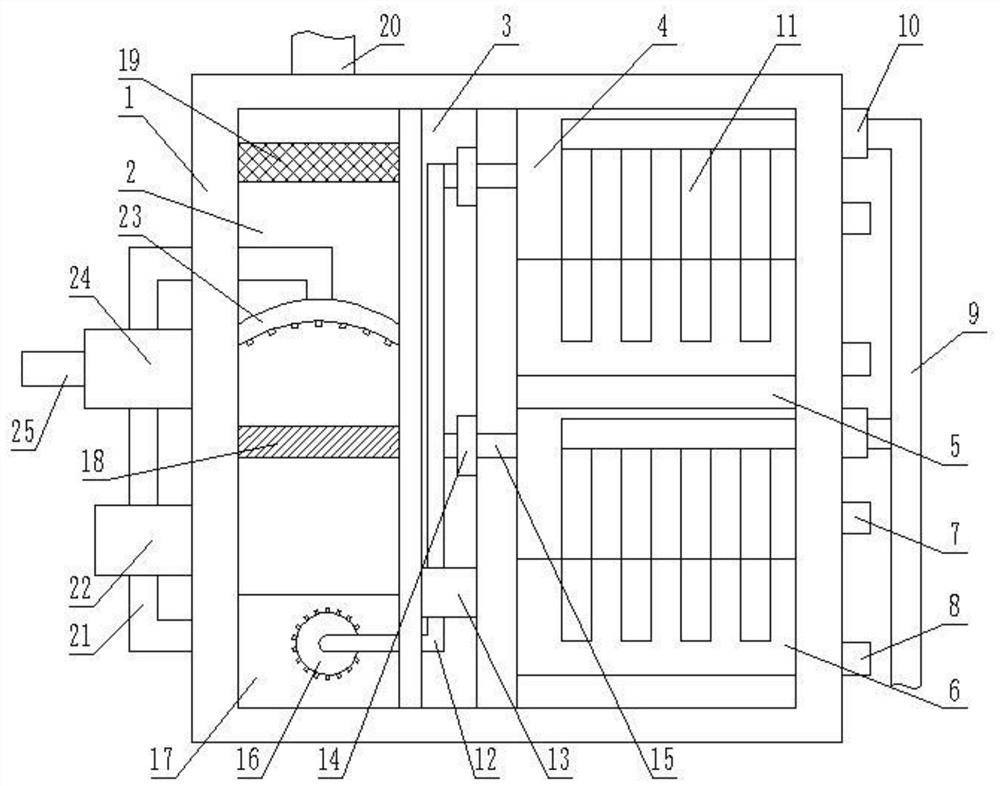

[0019] see Figure 1-2 , a high-efficiency desulfurization tower, including a tower body 1, the tower body 1 is in the shape of a cuboid, and a discharge tower 2 and a transfer tower 3 are arranged in parallel and sequentially discharged in the tower body 1, between the discharge tower 2 and the transfer tower 3 A sealing plate is provided, and two input towers 4 arranged side by side in the vertical direction are arranged on the other side of the transfer tower 3, and the two input towers 4 are separated by a partition 5, and the bottom of each input tower 4 is provided with a There is a lime slurry tank 6 with an opening at the top of the lime slurry tank 6. The lime slurry tank 6 is used to load lime slurry, and firstly purify the gas that needs to be desulfurized. The side of the tower body 1 is provided with an input pipe 9, and the input pipe 9 has Two branch pipes, the branch pipes are inserted into the input tower 4 one by one, and a plurality of shunt insertion pipes ...

Embodiment 2

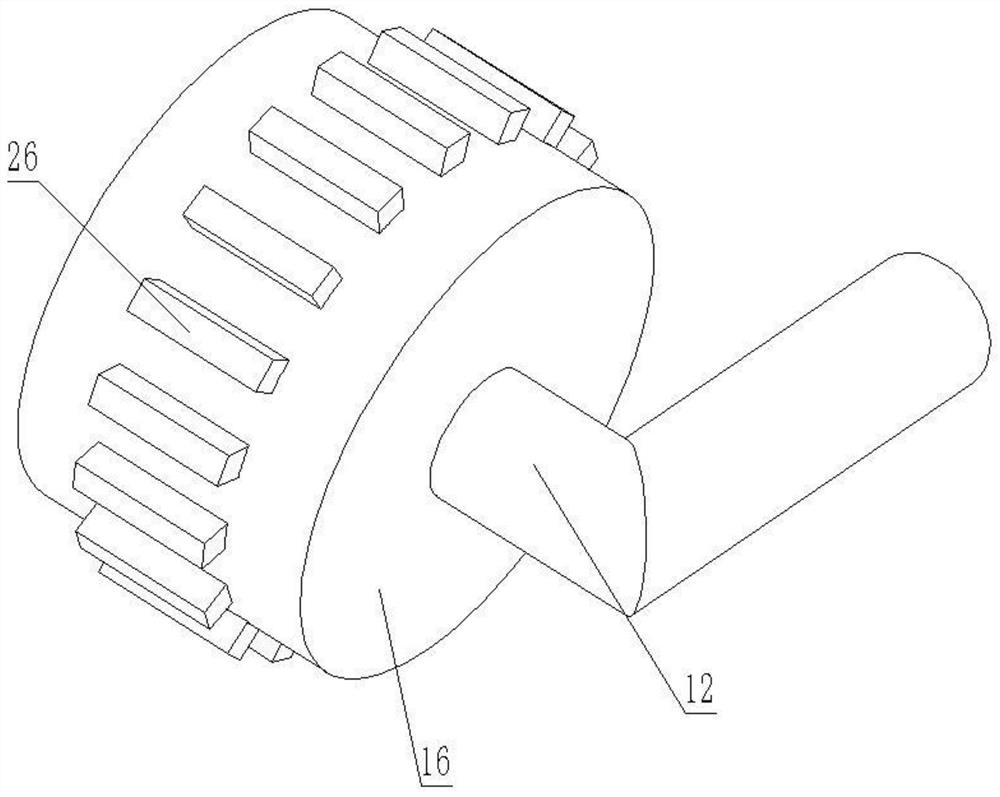

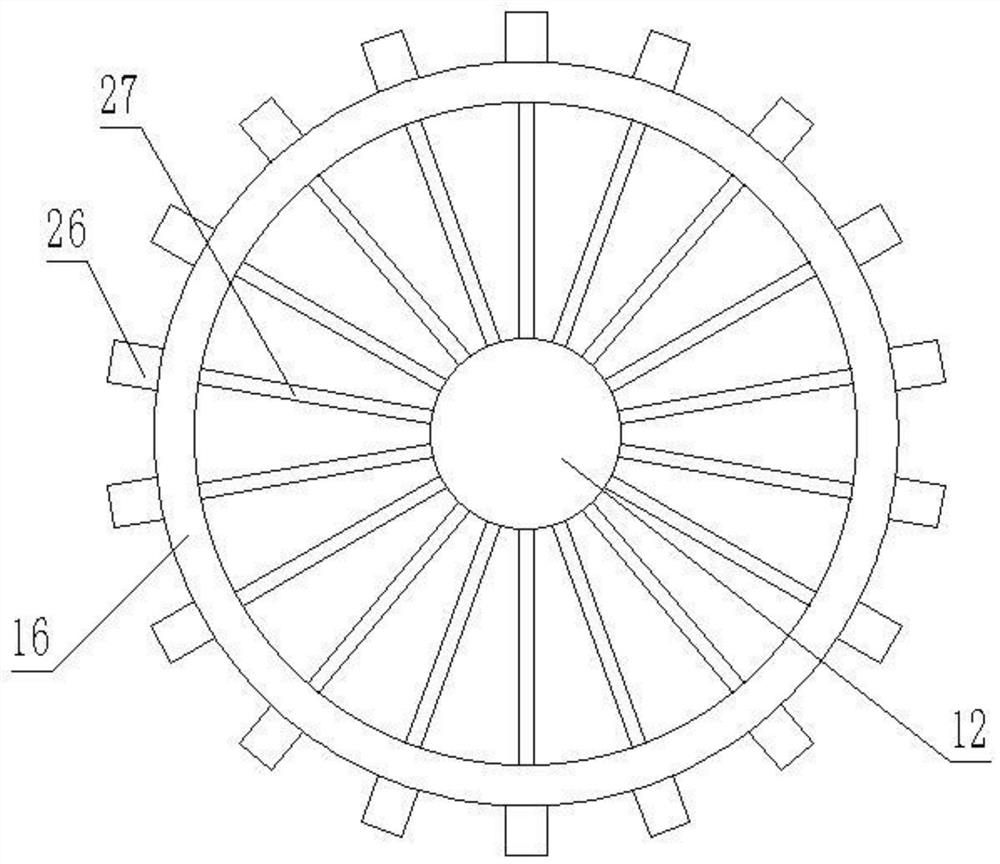

[0024] refer to image 3 On the basis of Embodiment 1, the front end of the transfer pipe 12 is in a closed state and extends into the air distribution pipe 16, and a plurality of internal pressurization connecting pipes 27 communicating with the transfer pipe 12 are arranged in the air distribution pipe 16, The diameter of described internal pressurization connecting pipe 27 is less than the width of protruding shower head 26, when carrying out the omnidirectional ejection of gas by gas distribution pipe 16, the speed when gas ejection can be improved through internal pressurization connecting pipe 27, thereby It has ensured that the protruding nozzle 26 positioned at the lower half of the gas distribution pipe 16 can carry out the gas ejection work smoothly, and the dispersion of the gas has been guaranteed, that is, the sufficient contact of the gas and the lye has been guaranteed.

Embodiment 3

[0026] On the basis of Example 1, a heat exchange tube is provided at the bottom of the lime slurry tank 6. When the lime slurry tank 6 is performing desulfurization work, the heat in the waste gas is transferred to the lime slurry, and by adding Cold water can both recover waste heat and avoid slurry splashing caused by excessive temperature in the lime slurry tank 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com