Sewage desulfurization system and desulfurization method

A technology of sewage and water inlet branch pipes, which is applied in the direction of chemical instruments and methods, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of inability to meet the requirements of effluent indicators, complex treatment process and operation, and sulfide content. Instability and other problems, to achieve the effect of reducing sulfur removal cost, improving sulfur removal efficiency, and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

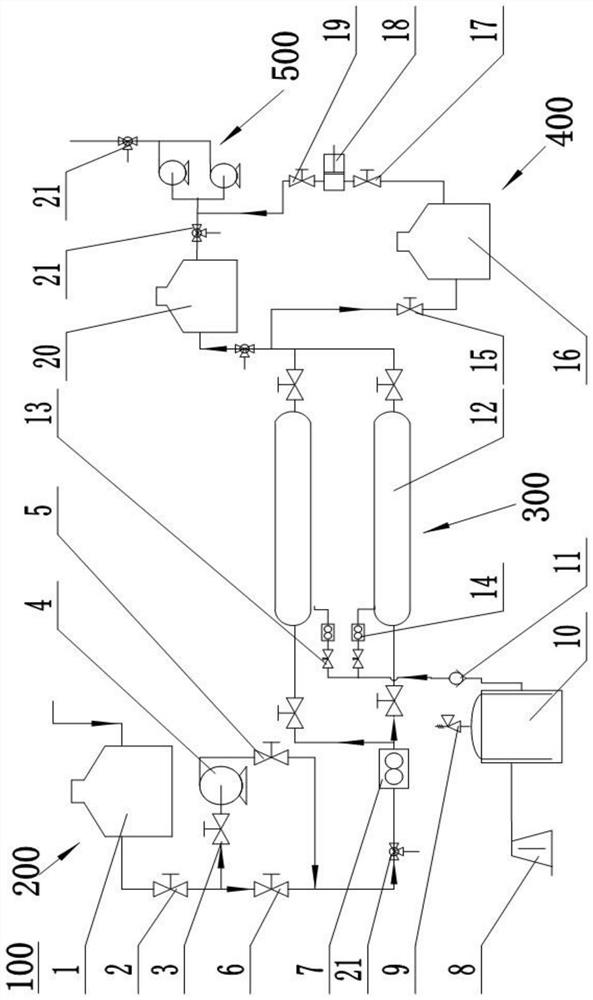

[0034] Such as figure 1 As shown, this embodiment provides a sewage desulfurization system 100, including a pretreatment unit 200, a mixing reaction unit 300, and a dosing unit 400. One end of the pretreatment unit 200 is used to communicate with the treatment station and to separate the sewage from solid and liquid. , and then separate the sewage from the insoluble matter therein, the other end of the pretreatment unit 200 communicates with one end of the mixing reaction unit 300, the sewage after solid-liquid separation enters the mixing reaction unit 300, and mixes and aerates in the mixing reaction unit 300 , increase the amount of air bubbles in the sewage, and then increase the contact area between the air and the sulfide in the sewage, and use the oxygen in the air to remove sulfur, which not only has low operating costs, but also does not cause any impact on equipment and pipelines, and improves the conversion of sulfide rate, the other end of the mixed reaction unit 3...

Embodiment 2

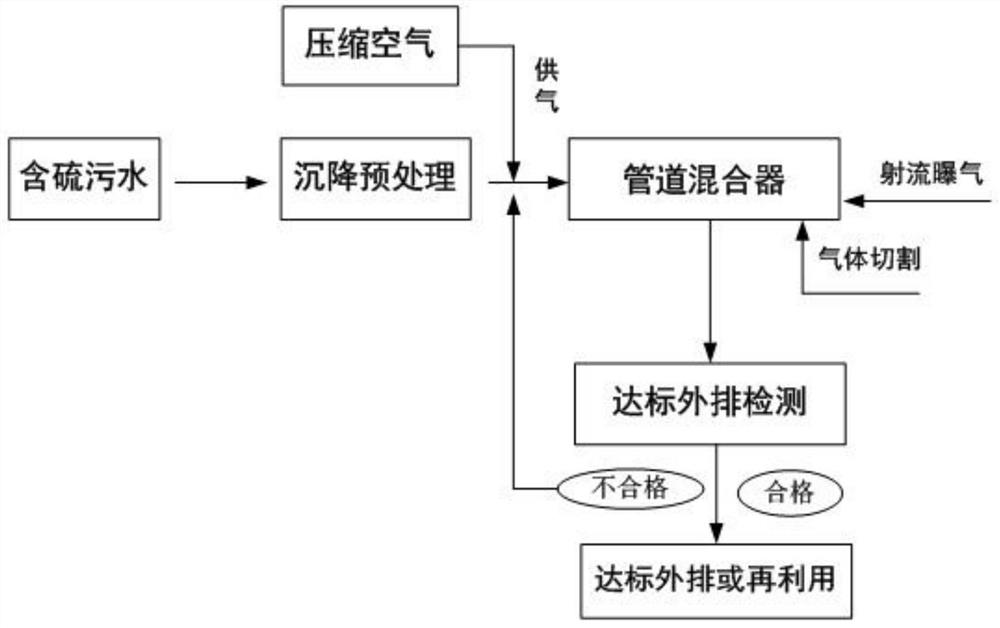

[0044] Such as figure 2 As shown, this embodiment provides a sewage desulfurization method, using the sewage desulfurization system 100 in Embodiment 1, including the following steps:

[0045] S1: Check the tightness of the connection of each valve, the switch is not blocked, and then make each valve in a closed state, and check that the pretreatment unit 200, the mixing reaction unit 300 and the dosing unit 400 can work normally;

[0046] S2: Start the main power supply, turn on the screw air compressor 8, inject compressed air into the air storage tank 10, introduce the sewage into the pretreatment unit 200, and conduct sedimentation and solid-liquid separation of the sewage through the pretreatment unit 200, Then the sewage is separated from the insoluble substances in it;

[0047] S3: start the centrifugal pump 4, introduce the sewage after solid-liquid separation into the pipeline mixer 12, then introduce the compressed air in the air storage tank 10 into the pipeline m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com