A nanobubble flotation device

A flotation device and nano-bubble technology, applied in flotation, solid separation, etc., can solve the problem that it is difficult to fully recover fine-grained minerals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

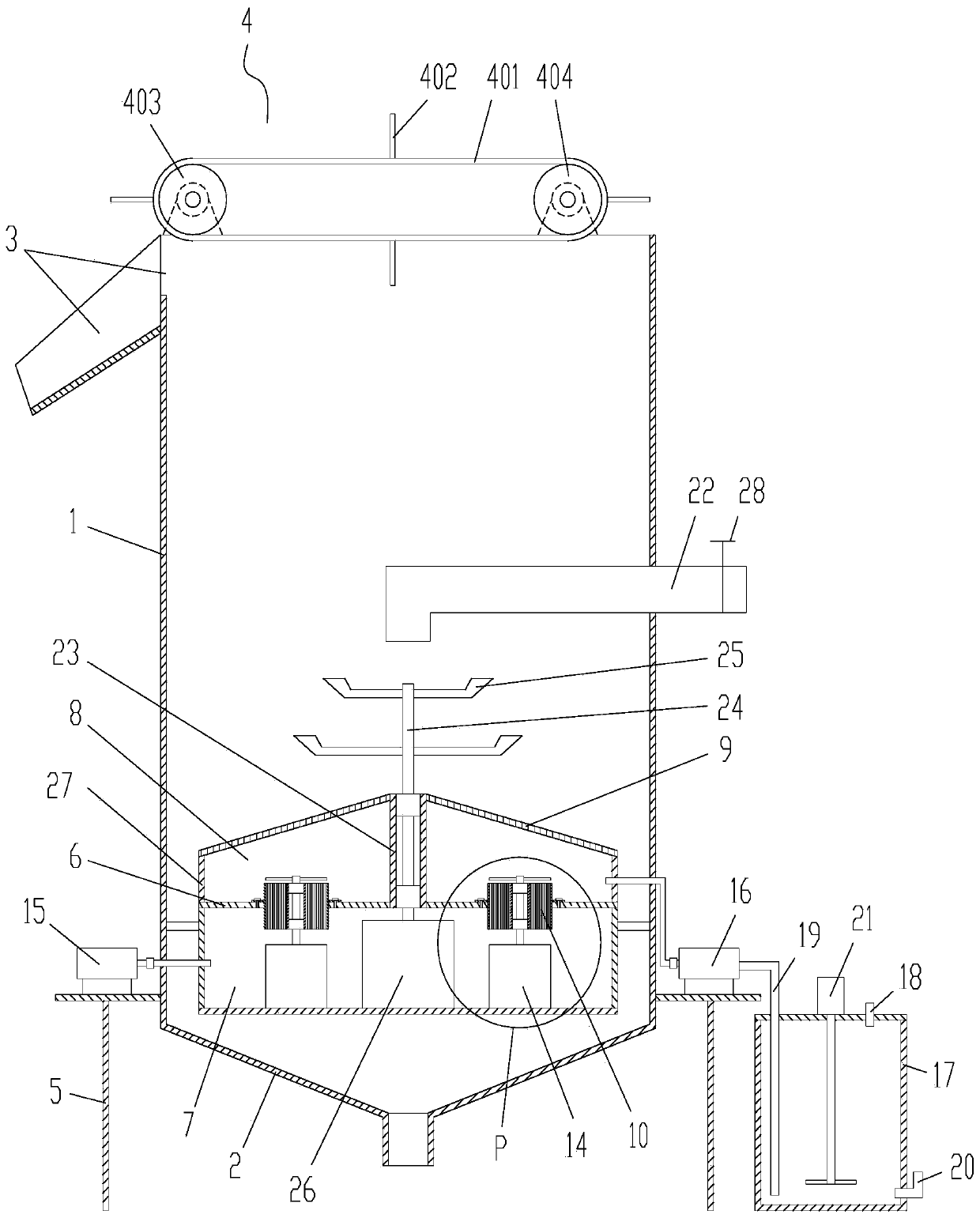

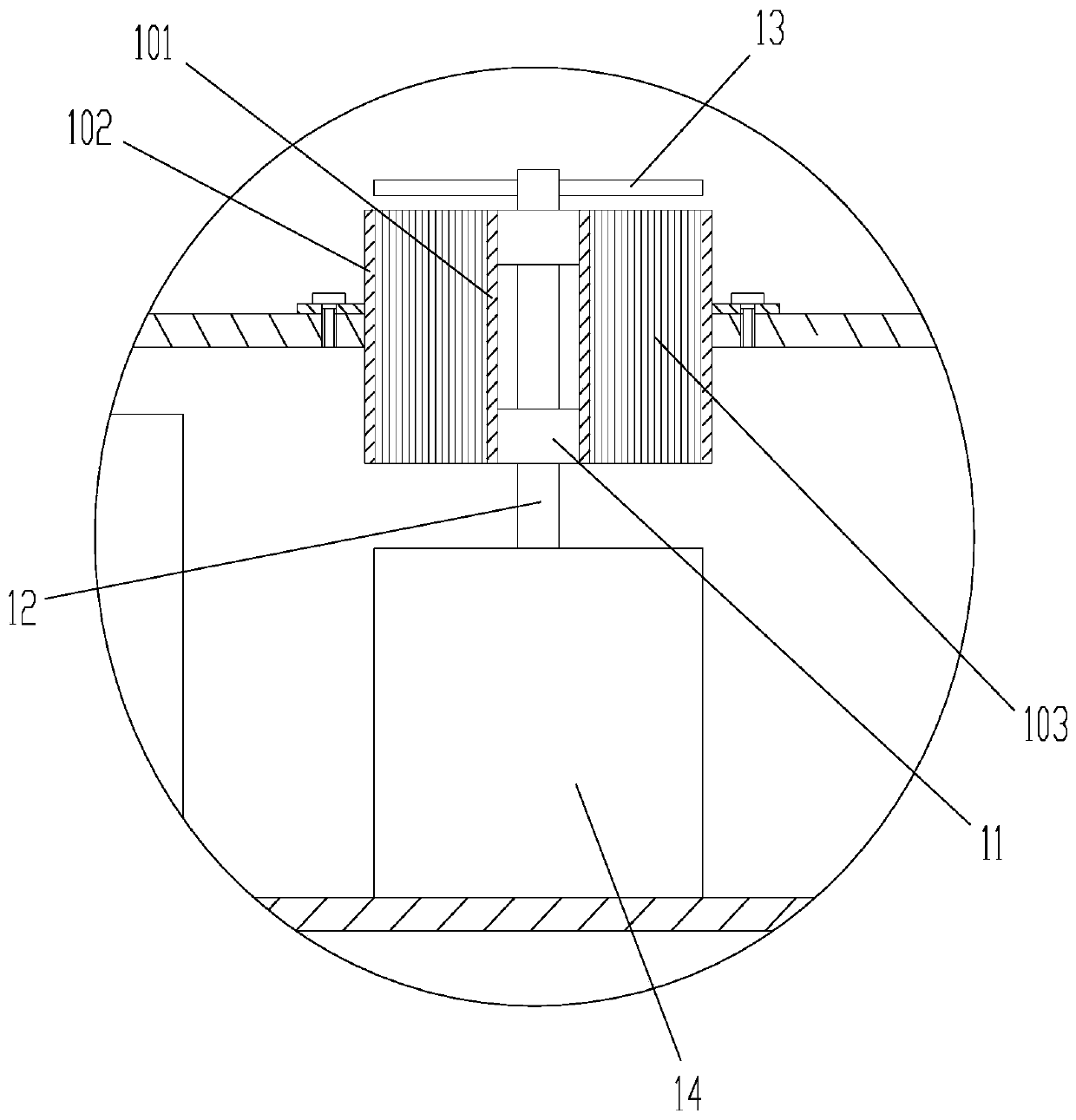

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] As shown in the figure, the nano-bubble flotation device of this embodiment includes a vertically arranged rectangular tubular casing 1, the lower end of which is connected to a funnel-shaped waste collection and discharge bucket 2, and the rectangular tubular casing One side of the upper end is provided with a foam discharge port 3, and the upper end of the rectangular tubular shell is also provided with a bubble scraper 4 that drives the foam to the foam discharge port; the outer side of the lower end of the rectangular tubular shell is also connected with a support frame 5 .

[0019] In this embodiment, the foam scraper 4 includes a belt 401, a foam scraper 402 arranged on the outer surface of the belt, a driving pulley 403 and a driven pulley 404 arranged on a rectangular tubular housing and matched with the belt, and a driving pulley. A thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com